System and technology for continuously concentrating and collecting crystals

A process and system pressure technology, applied in the field of solvent extraction process, can solve the problems of difficult control of product quality and product yield, many operators, high labor costs, etc., and achieve the effects of reduced labor, overall investment and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

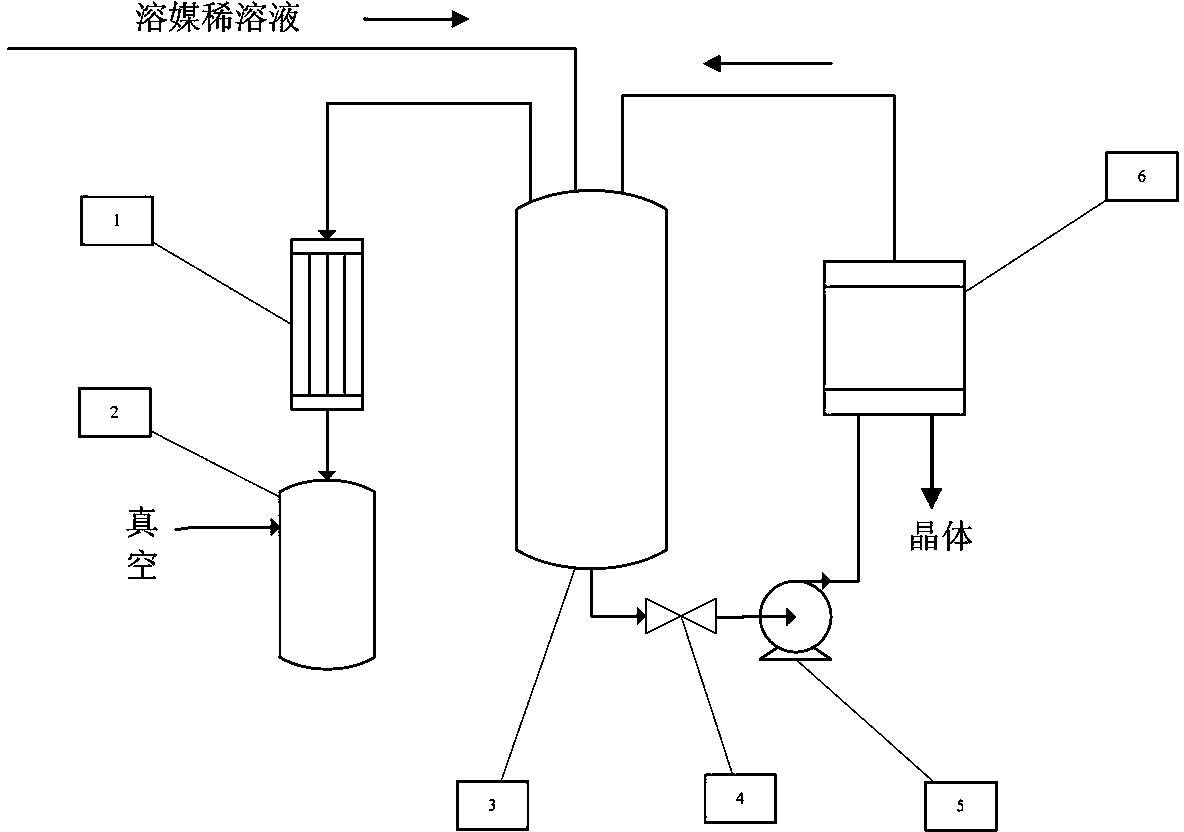

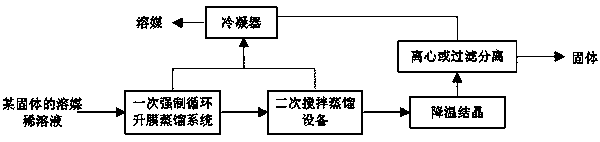

[0018] like figure 1 As shown, the continuous concentration crystal mining system is a closed-circuit circulation system formed by a fluidly connected high-efficiency distiller 3, a solvent condenser 1, a solvent receiving tank 2, a delivery pump 5, and a crystallizer 6, which can realize solvent distillation and continuous crystallization. Function. The upper part of the high-efficiency distiller 3 is respectively in fluid communication with the upper part of the solvent condenser 1 and the upper part of the crystallizer 6 through a circulation pipeline. The lower part of the high-efficiency distiller 3 and the lower part of the crystallizer 6 are communicated through a flow pipeline, and a valve 4 and a delivery pump 5 are installed on the flow pipeline. The lower part of the solvent condenser 1 is connected with the solvent receiving tank 2 through a circulation pipeline. The bottom of the crystallizer 6 is connected to a crystal collection device for continuous crystal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com