Amination-acidification modified activated carbon material

An activated carbon and modified technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of corrosion equipment, limited increase of double capacitance value, limited specific surface area value, etc., to reduce self-discharge and increase pseudo Capacitance value, the effect of increasing the specific capacitance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

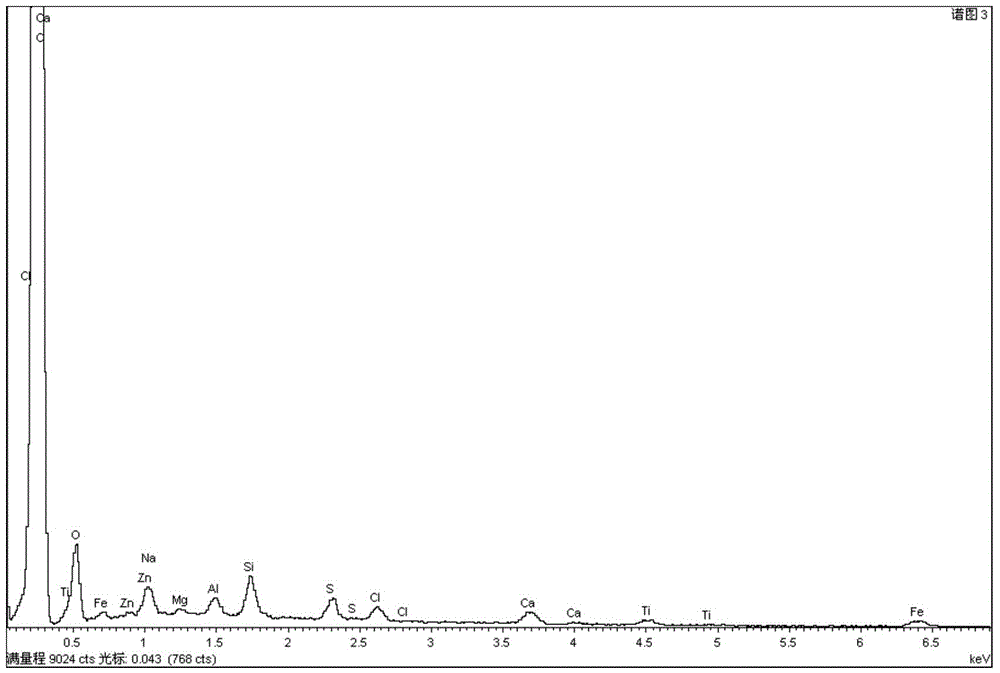

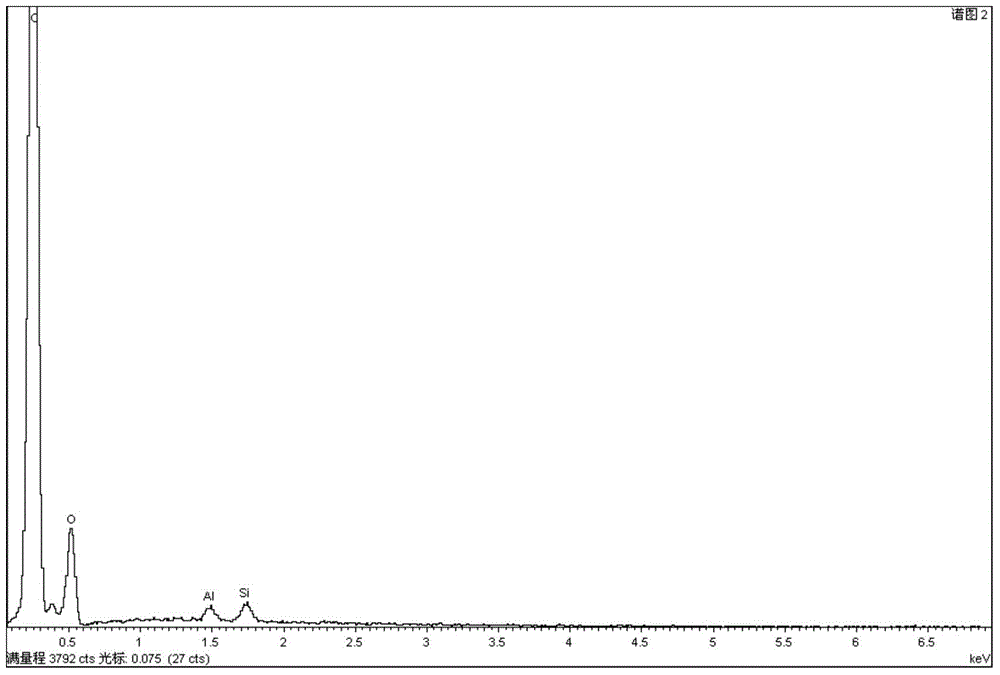

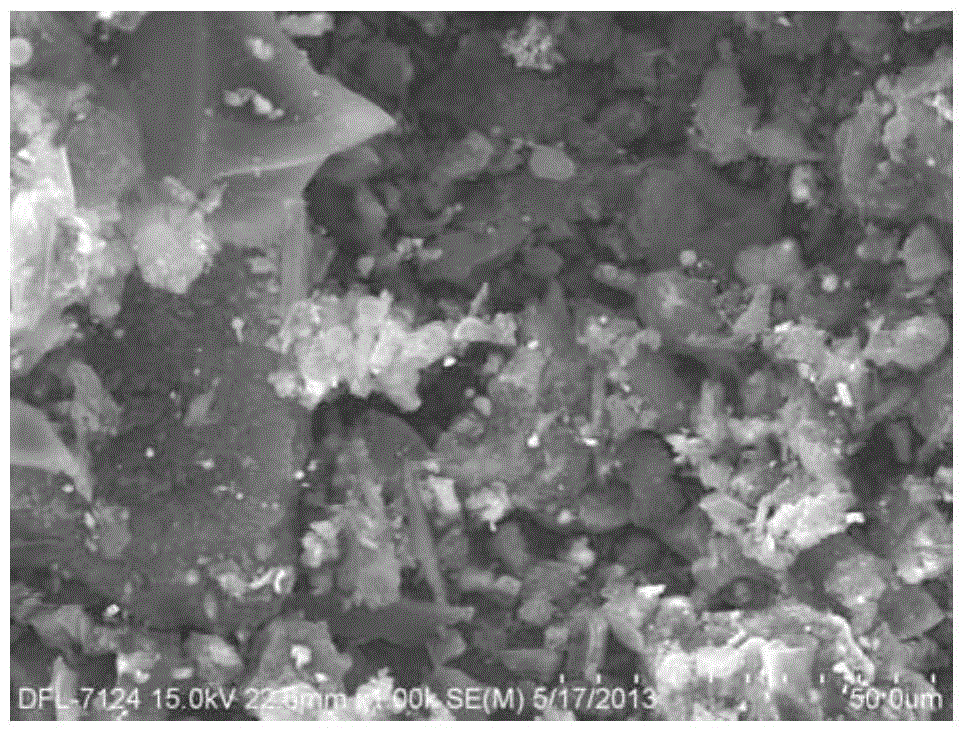

Image

Examples

Embodiment 1

[0025] (1) Weigh 0.4g of activated carbon and 0.8g of sodium dodecylbenzenesulfonate, add 60mL of 1M H 2 SO 4 Medium, ultrasonic 30min;

[0026] (2) Add 1.8mL of aniline into the solution obtained in (1), stir rapidly, and then stir at 0°C for 2h;

[0027] (3) Weigh 1.88g of ammonium persulfate to prepare a solution, add it to the solution in step (2) at a rate of 1 drop per second, and then continue to stir the mixed solution at 0°C for 6 hours;

[0028] (4) Filter the solution obtained after the reaction in step (3) to obtain a black-green solid, which is washed continuously with deionized water and alcohol, and then dried in a vacuum oven at 70°C for 6 hours;

[0029] (5) Put the black-green solid obtained in (4) into a tube furnace at a heating rate of 5°C / min, heat up to 600°C, 700°C, and 800°C for carbonization, and keep it warm for two hours to form N-rich carbon materials;

[0030] (6) Pour concentrated nitric acid (63% to 68% by mass) into the solid obtained in st...

Embodiment 2

[0033] (1) Weigh 0.4g of activated carbon and 1.6g of sodium dodecylbenzenesulfonate, add 60mL of 1M H 2 SO 4 Medium, ultrasonic 30min;

[0034] (2) Add 3.6mL of aniline to the solution obtained in (1), stir rapidly, and then stir at 0°C for 2h;

[0035] (3) Weigh 3.76g of ammonium persulfate to form a solution, add it to the solution in step (2) at a rate of 1 drop per second, and then continue to stir the mixed solution at 0°C for 6 hours;

[0036] (4) Filter the solution obtained after the reaction in step (3) to obtain a black-green solid, which is washed continuously with deionized water and alcohol, and then dried in a vacuum oven at 70°C for 6 hours;

[0037] (5) Put the black-green solid obtained in (4) into a tube furnace at a heating rate of 5°C / min, heat up to 600°C, 700°C, and 800°C for carbonization, and keep it warm for two hours to form N-rich carbon materials;

[0038] (6) Add concentrated nitric acid (63% to 68% by mass) to the solid obtained in step (5) u...

Embodiment 3

[0041] (1) Weigh 0.4g of activated carbon and 0.8g of sodium dodecylbenzenesulfonate, add 60mL of 1M H 2 SO 4 Medium, ultrasonic 30min;

[0042] (2) Add 1.8mL of aniline into the solution obtained in (1), stir rapidly, and then stir at 0°C for 2h;

[0043] (3) Weigh 1.88g of ammonium persulfate to prepare a solution, add it to the solution in step (2) at a rate of 1 drop per second, and then continue to stir the mixed solution at 0°C for 6 hours;

[0044] (4) Filter the solution obtained after the reaction in step (3) to obtain a black-green solid, which is washed continuously with deionized water and alcohol, and then dried in a vacuum oven at 70°C for 6 hours;

[0045] (5) Put the black-green solid obtained in (4) into a tube furnace at a heating rate of 5°C / min, heat up to 600°C, 700°C, and 800°C for carbonization, and keep it warm for two hours to form N-rich carbon materials;

[0046] (6) Add concentrated nitric acid (63% to 68% by mass) to the solid obtained in step (5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com