Side stream causticization method and apparatus of Bayer process alumina production

An alumina and Bayer process technology, applied in alumina/aluminum hydroxide and other directions, can solve the problems of increased energy consumption, the impact of decomposition speed, complex process flow, etc., to reduce energy consumption, reduce investment and operating costs, and simplify the process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

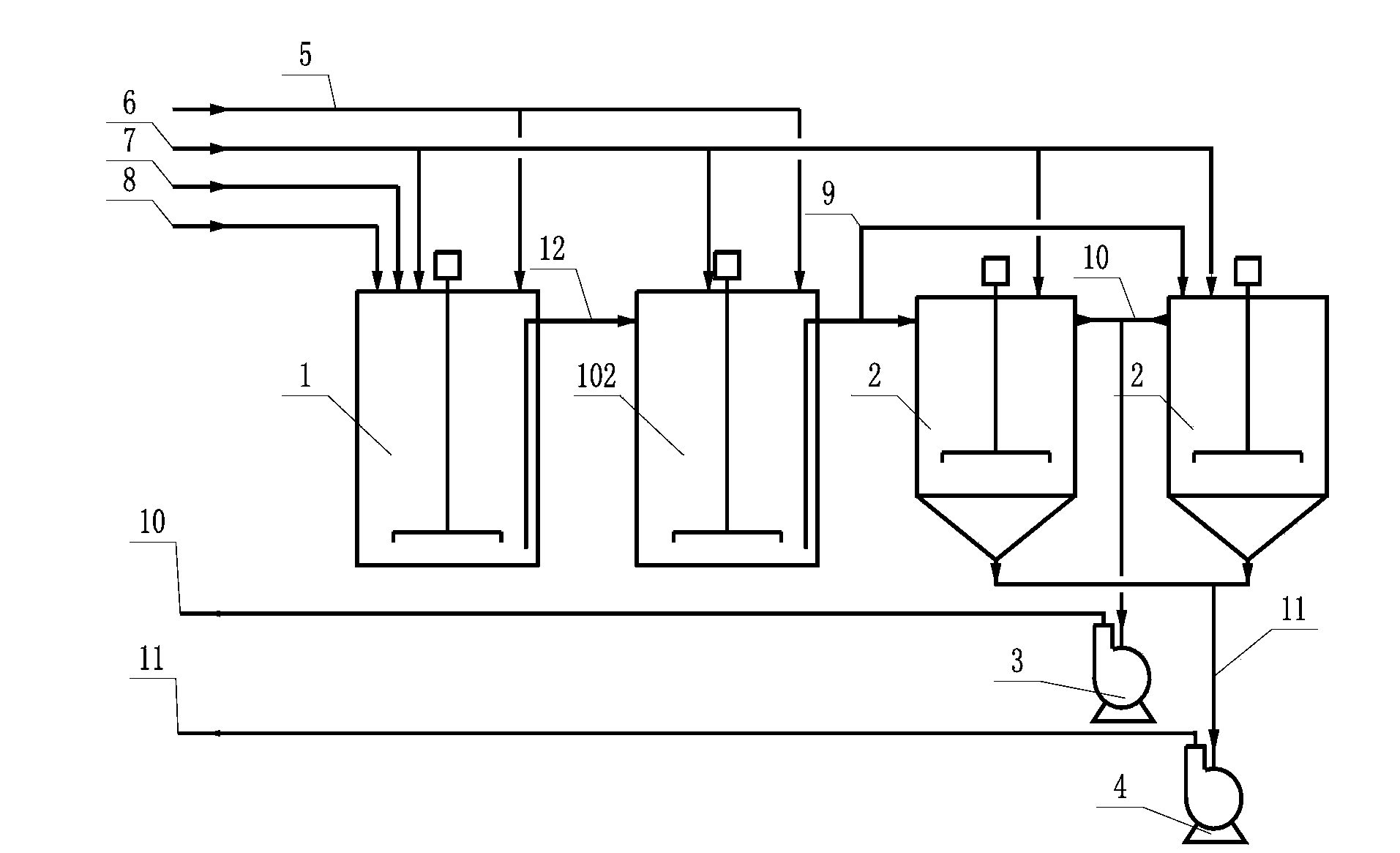

Embodiment 1

[0023] This embodiment is causticizing step by step, such as figure 1 As shown, the secondary or tertiary washing liquid from the red mud separation and washing process is used as the causticizing raw liquid 7 and entered into the first tank 1 of the causticizing tank, and the lime milk 8 is added to the first tank 1 of the causticizing tank, and the material is fed to the causticizing tank. Pass into compressed air 5 to make the causticizing solution 12 enter the secondary causticizing tank 102, stay in the secondary causticizing tank for at least 2 hours and stir evenly, after causticizing, the solution 9 enters the settling tank 2 for solid-liquid separation, and the settling tank The overflow 10 is the causticized liquid pumped to the red mud separation and washing process by the causticized liquid pump 3 for one or two washing settling tanks, and the bottom flow of the settling tank 11 is the causticized slag pumped to the red mud separation and washed by the causticized s...

Embodiment 2

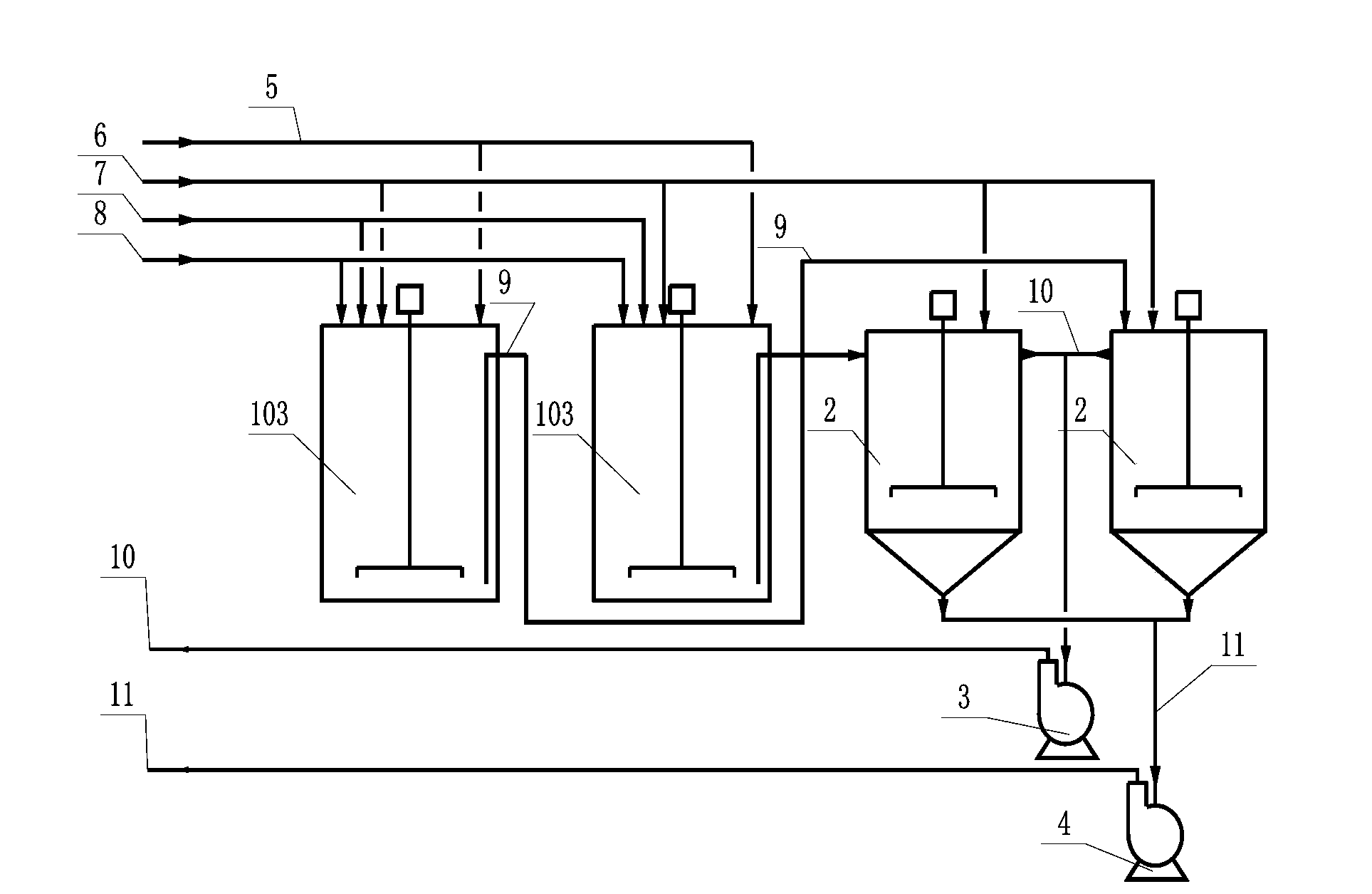

[0028] This embodiment is simultaneous causticization

[0029] Such as figure 2 As shown, the difference between this embodiment and embodiment 1 is that the secondary or tertiary washing liquid from the red mud separation and washing process enters each causticizing tank 103 as the causticizing stock solution 7 and lime milk 8, and the others are the same as in the embodiment 1. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com