Reverse osmosis-based high-concentration sewage treatment method

A sewage treatment method and reverse osmosis technology, applied in the direction of osmosis/dialysis water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of hydraulic explosive diffusion, short service life of equipment, Unstable effluent effect and other problems, to achieve the effect of reducing membrane fouling, prolonging life, and reducing fouling on the membrane surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

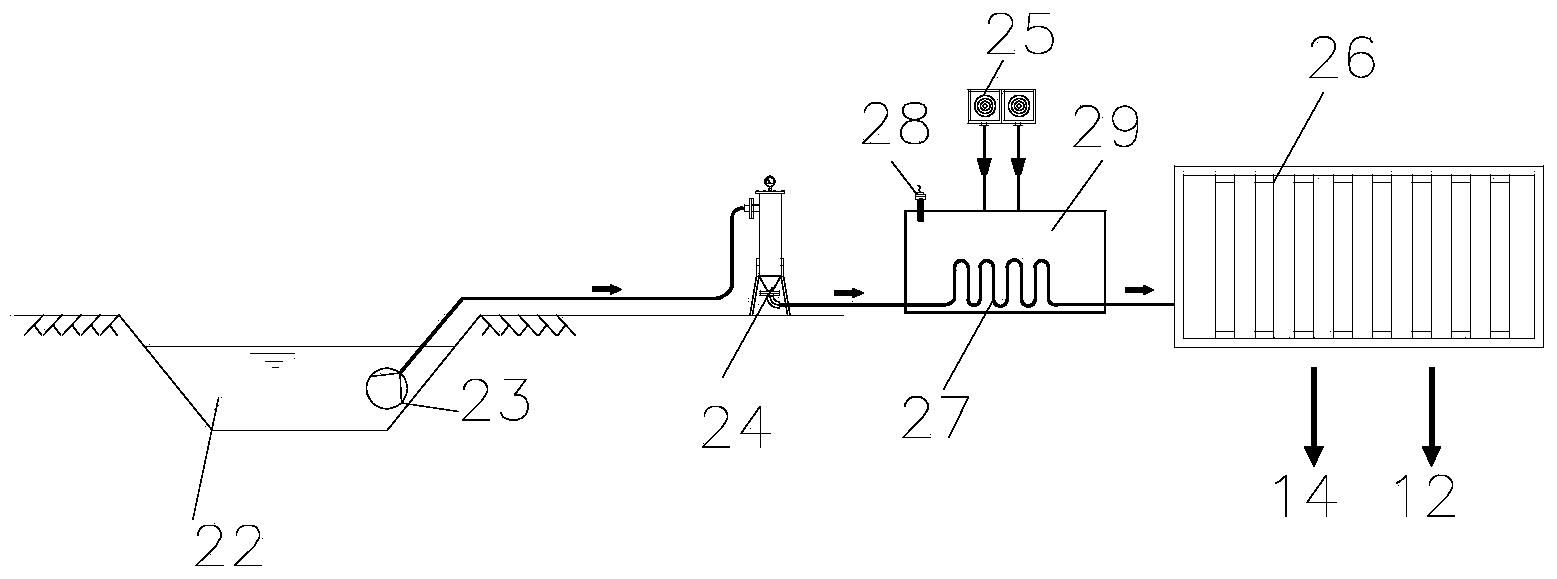

[0049] Such as figure 1 Shown, a kind of processing method of the landfill leachate based on reverse osmosis of the present invention, the method may further comprise the steps:

[0050] (1) Pre-filtering treatment:

[0051] Such as figure 1 As shown in , a leachate lifting pump 23 is installed in the leachate regulating tank 22, and the landfill leachate to be treated enters the filter 24 through the lift pump 23, and the large particles in the raw water of the landfill leachate are removed in the filter 24 And impurities are filtered out to ensure less impurities in landfill leachate.

[0052] (2) Preheating treatment:

[0053] The pre-filtered landfill leachate is transported to the pre-heating device 25 through pipelines for pre-heating treatment; Heat, the preheated heat transfer medium circulates in the heating pipe 27, transfers heat to the landfill leachate in the leachate preheating pool 29, and the leachate preheats the pool through the temperature controller 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com