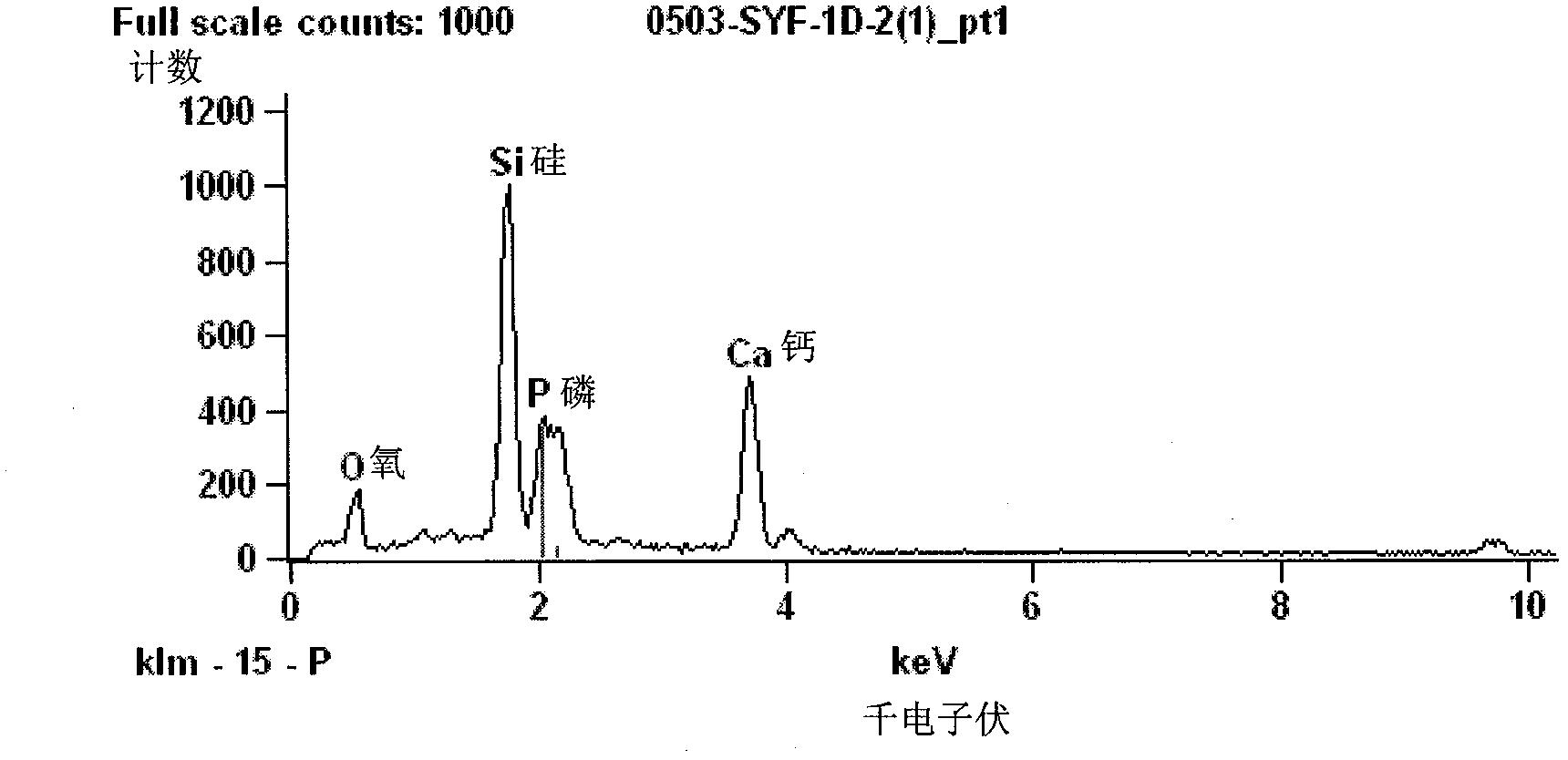

Method for preparing micron-sized biological activity glass and application thereof in departments of orthopedics and dentistry

A bioactive glass and solution technology, applied in dentistry, dental preparations, dental prostheses, etc., to achieve the effect of simple equipment and low raw material prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

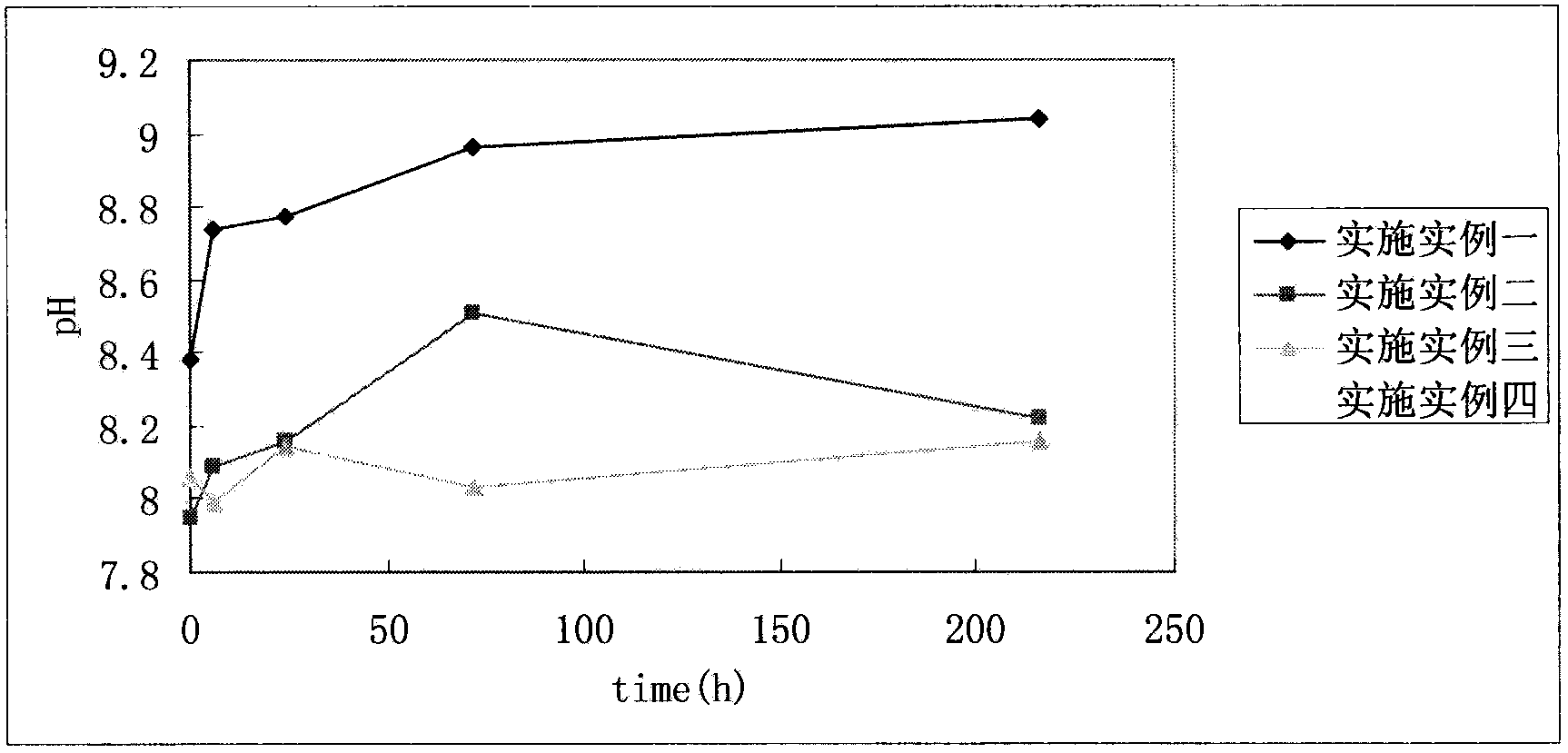

Embodiment 1

[0026] 1) Add 7ml of concentrated nitric acid to 53g of absolute ethanol and mix to obtain solution I;

[0027] 2) Add 24.17g of ethyl orthosilicate to solution I, pre-hydrolyze for 30min (room temperature, 1000rpm) to obtain solution II;

[0028] 3) Add 1.7g of phosphorus pentoxide to solution II, stir at 1000rpm for 30min, to obtain solution III;

[0029] 4) Add 17g of calcium nitrate tetrahydrate to solution III, stir at 1000rpm for 1h, fully dissolve and form a clear gel.

[0030] 5) Place the clear gel in a closed container and age it in an oven at 60°C for 72 hours to form a gel;

[0031] 6) Dry the gel in an oven at 130°C for 72 hours, sieving by ball milling to obtain dry gel powder;

[0032] 7) The dry gel powder is calcined at 700° C. for 2 hours to obtain bioactive glass powder.

Embodiment 2

[0034] 1) Add 7ml of concentrated nitric acid to 53g of absolute ethanol and mix to obtain solution I;

[0035] 2) Add 24.17g of ethyl orthosilicate to solution I, pre-hydrolyze for 30min (room temperature, 1000rpm) to obtain solution II;

[0036] 3) Add 2.83g of phosphorous pentoxide to solution II, stir at 1000 rpm for 30 minutes to obtain solution III;

[0037] 4) Add 15.11 g of calcium nitrate tetrahydrate to solution III, stir at 1000 rpm for 1 hour, and fully dissolve to form a clear gel.

[0038] 5) Place the clear gel in a closed container and age it in an oven at 60°C for 72 hours to form a gel;

[0039] 6) Dry the gel in an oven at 130°C for 72 hours, sieving by ball milling to obtain dry gel powder;

[0040] 7) The dry gel powder is calcined at 700° C. for 2 hours to obtain bioactive glass powder.

Embodiment 3

[0042] 1) Add 7ml of concentrated nitric acid to 53g of absolute ethanol and mix to obtain solution I;

[0043] 2) Add 24.17g of ethyl orthosilicate to solution I, pre-hydrolyze for 30min (room temperature, 1000rpm) to obtain solution II;

[0044] 3) Add 4.25g of phosphorous pentoxide to solution II, stir at 1000 rpm for 30 minutes to obtain solution III;

[0045] 4) Add 12.75g of calcium nitrate tetrahydrate to solution III, stir at 1000 rpm for 1 hour, fully dissolve and form a clear gel.

[0046] 5) Place the clear gel in a closed container and age it in an oven at 60°C for 72 hours to form a gel;

[0047] 6) Dry the gel in an oven at 130°C for 72 hours, sieving by ball milling to obtain dry gel powder;

[0048] 7) The dry gel powder is calcined at 700° C. for 2 hours to obtain bioactive glass powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com