Paste resin and composite cloth for composite cloth

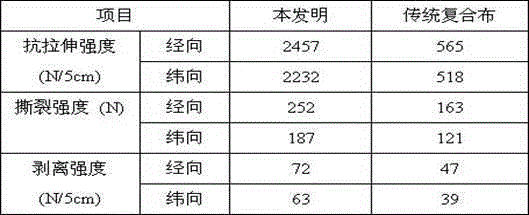

A paste resin and composite cloth technology, applied in the field of advertising, can solve the problems of short service life, increased production costs, uneven coating, etc., and achieve the effects of excellent tensile strength, long service life and good softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A paste resin for composite cloth, the paste resin is composed of the following components in parts by weight: 100 parts of PVC paste resin, 120 parts of plasticizer, 2 parts of stabilizer, and 35 parts of environmentally friendly solvent oil , 30 parts of ethyl ester diluent, 20 parts of adhesive, and 20 parts of benzoic acid inhibitor.

[0027] The general pasty resin will be cured and agglomerated within 10-30 minutes, while the pasty resin of the present invention can maintain a certain viscosity for 8-12 hours in an open state without curing.

Embodiment 2

[0029] A paste resin for composite cloth, the paste resin is composed of the following components in parts by weight: 100 parts of PVC paste resin, 110 parts of dioctyl phthalate, and 3 parts of barium-zinc stabilizer , 25 parts of D80 solvent oil, 25 parts of ethoxyethyl acrylate, 15 parts of polyacrylate, and 15 parts of butyl p-hydroxybenzoate.

[0030] The general pasty resin will be cured and agglomerated within 10-30 minutes, while the pasty resin of the present invention can maintain a certain viscosity for 8-12 hours in an open state without curing.

Embodiment 3

[0032] A composite cloth is prepared by the following steps: using mesh cloth as a skeleton material, after being impregnated with a paste resin, drying and pre-forming, hot-melting and pasting a PVC film on both sides of the skeleton material, and then embossing , made after cooling, shaping and trimming;

[0033] Wherein, the paste resin is composed of the following components in parts by weight: 100 parts of PVC paste resin, 120 parts of triethyl citrate, 2 parts of calcium zinc stabilizer, 35 parts of D80, 30 parts of diethyl ester, isocyanate 20 parts, 20 parts of butyl parahydroxybenzoate;

[0034] During the dipping process, control the dipping amount to 28g / m 2 ;

[0035] During the pre-setting process of drying, the control temperature is 110℃;

[0036] The temperature of thermal lamination was controlled at 165°C, the lamination pressure was 320N, and the lamination speed was 13m / min.

[0037] In the open state, the paste resin of the present invention can mainta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com