Electrostatic spraying PE op-coat paint

An electrostatic spraying and clear topcoat technology, applied in the field of coatings, can solve problems such as low work efficiency and difficult construction, and achieve the effects of facilitating construction, reducing construction difficulty and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In this embodiment, a PE clear finish paint by electrostatic spraying includes components:

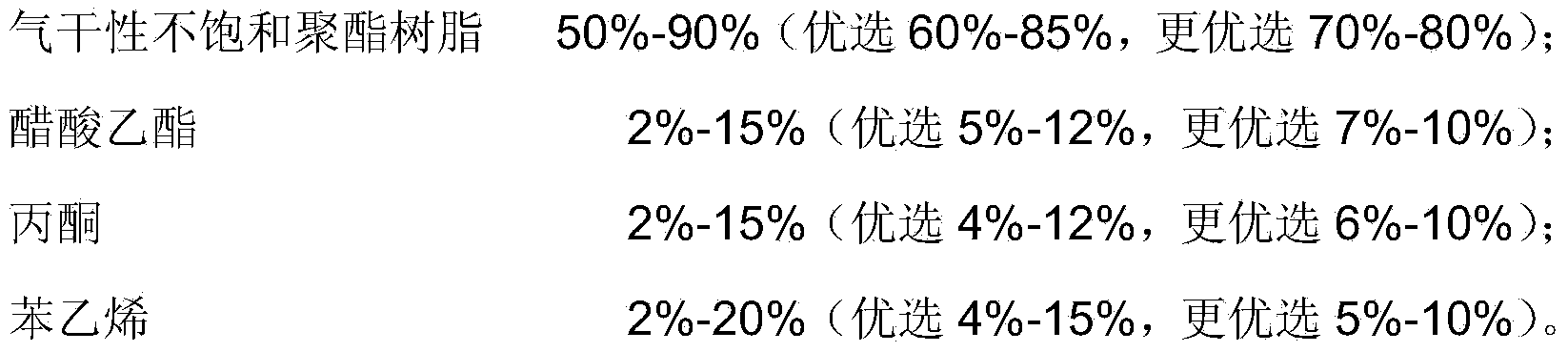

[0035] Main agent:

[0036]

[0037]

[0038] Accelerator:

[0039] Mass concentration is 6% cobalt isooctanoate 1kg;

[0040] Initiator:

[0041] 1.2 kg of methyl ethyl ketone peroxide with an effective oxygen content of 10%.

[0042] When preparing the PE clear topcoat in this example, first prepare the main agent, stir evenly, then add the accelerator and stir evenly, then add the initiator, stir evenly, and carry out electrostatic spraying.

Embodiment 2

[0044] In this embodiment, a PE clear finish paint by electrostatic spraying includes components:

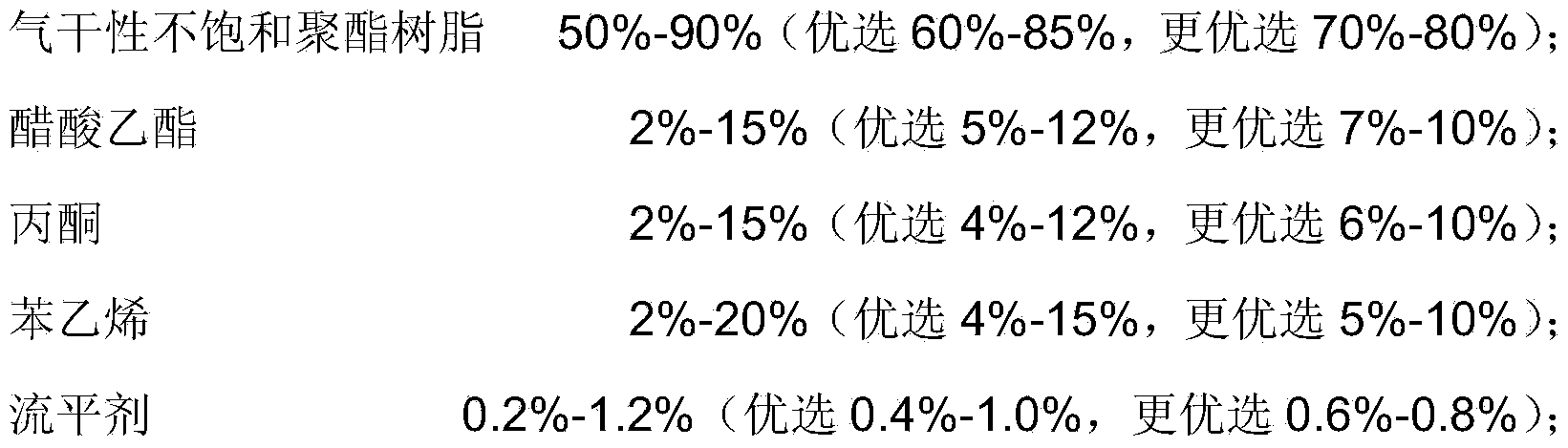

[0045] Main agent:

[0046]

[0047] Accelerator:

[0048] 1.1kg of cobalt isooctanoate with a mass concentration of 6%;

[0049] Initiator:

[0050] 1 kg of methyl ethyl ketone peroxide with an effective oxygen content of 10%.

[0051] When preparing the PE clear topcoat in this example, first prepare the main agent, stir evenly, then add the accelerator and stir evenly, then add the initiator, stir evenly, and carry out electrostatic spraying.

Embodiment 3

[0053] In this embodiment, a PE clear finish paint by electrostatic spraying includes components:

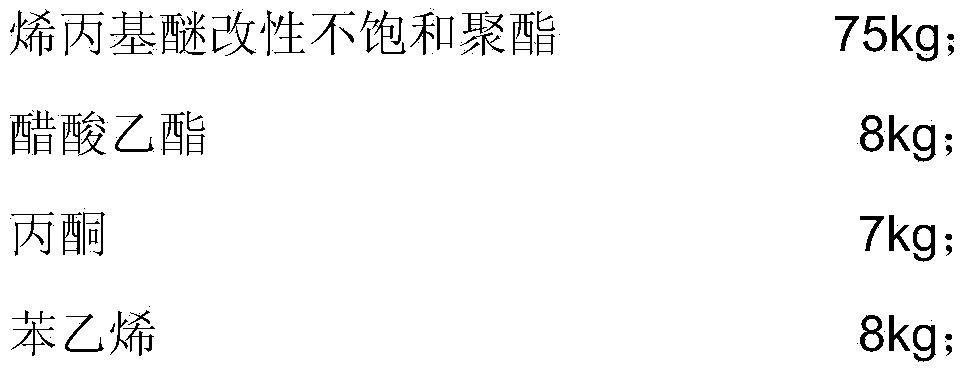

[0054] Main agent:

[0055]

[0056] Accelerator:

[0057] 1.2kg of cobalt isooctanoate with a mass concentration of 6%;

[0058] Initiator:

[0059] 1.3 kg of methyl ethyl ketone peroxide with an effective oxygen content of 10%.

[0060] When preparing the PE clear topcoat in this example, first prepare the main agent, stir evenly, then add the accelerator and stir evenly, then add the initiator, stir evenly, and carry out electrostatic spraying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com