RF power supply with digitally adjustable RF signal phase

A technology of radio frequency signal and radio frequency power supply, applied in electrical components, output power conversion devices, plasma, etc., can solve problems such as large phase difference, processing failure, plasma oscillation, etc., to eliminate signal phase difference and improve process stability performance, to avoid the effect of crosstalk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

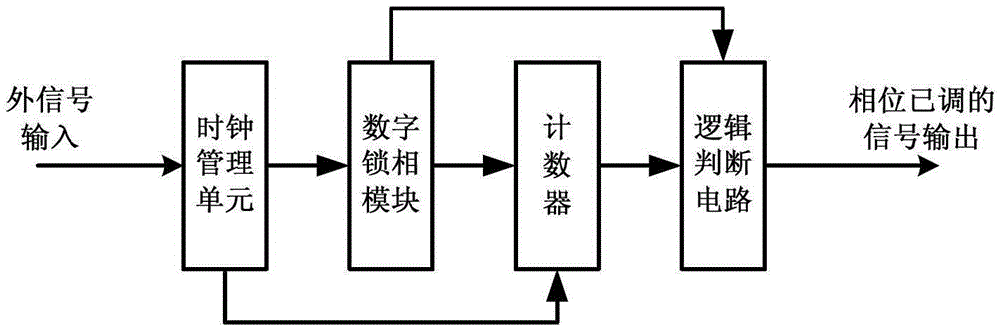

[0034] Such as image 3As shown, Embodiment 1 discloses a schematic circuit diagram of the phase adjustment circuit in the embodiment of the present invention. The phase adjustment circuit can be composed of devices with independent functions, including a clock management unit, a digital phase lock module, a counter and a logic judgment circuit.

[0035] The clock management unit accesses the external input signal, and after the signal is conditioned by filtering and shaping, it is sent as the reference clock signal CLKIN to the digital phase-locking module and the counter respectively.

[0036] The digital phase-locking module performs frequency multiplication processing on the reference clock signal CLKIN, and the multiple can be 2 to 360 times. After frequency multiplication, the frequency multiplication signal CLKX is obtained, and is output to the counter and logic judgment circuit.

[0037] The counter includes a phase-shift counter and a hold counter, wherein the phase...

Embodiment 2

[0047] Such as Figure 4 As shown, Embodiment 2 discloses another schematic circuit diagram of the phase adjustment circuit in the embodiment of the present invention. The phase adjustment circuit can use a programmable logic device (such as a field programmable logic gate device FPGA) to realize the phase adjustment circuit, Figure 4 The functions of each component in the image 3 The corresponding parts in the same.

Embodiment 3

[0049] Such as Figure 5 As shown, Embodiment 3 discloses another schematic circuit diagram of the phase adjustment circuit in the embodiment of the present invention. The phase adjustment circuit can use a special integrated chip to realize the phase adjustment circuit, Figure 5 The functions of each component in the image 3 The corresponding parts in the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com