Soy protein curd product and preparation method thereof

A technology of soybean protein and soybean protein isolate, which is applied in the field of soybean protein curd products and its preparation, can solve the problems of unpleasant powdery taste, affecting consumers' acceptance of soybean protein isolate products, and low soybean protein content, and achieves Effects of weight control and health, rich taste, delicate and smooth taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

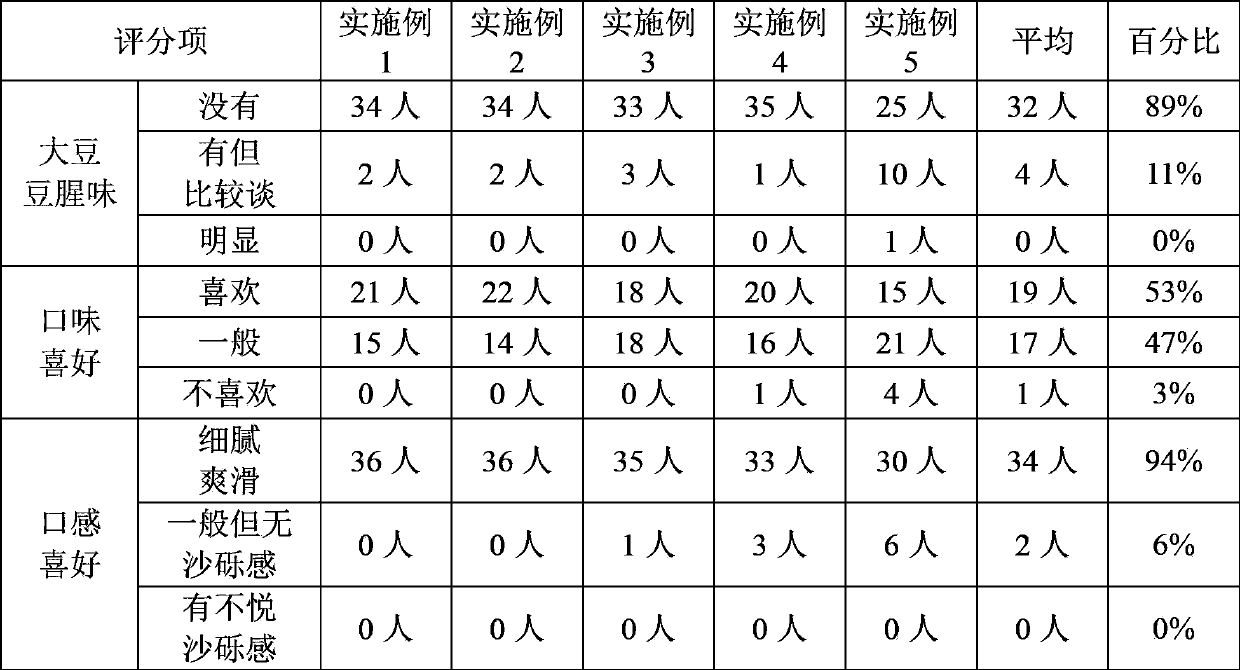

Examples

Embodiment 1

[0025] The components of the soybean protein curd product contain (parts by weight): isolated soybean protein 5.5, whole milk powder 3, skim milk powder 2, fructose syrup 6, maltitol 0.8, gluconolactone 0.3, pectin 0.05 , gelatin 0.1, blueberry essence 0.1, blueberry jam 7, strawberry jam 2, water 75.

[0026] The preparation steps of the soybean protein curd product are as follows:

[0027] (1) Mixing: Mix 5.5 parts by weight of soybean protein isolate, 3 parts by weight of whole milk powder, 2 parts by weight of skim milk powder, 6 parts by weight of fructose syrup, and 0.8 parts by weight of maltitol, and then add 75 parts by weight of water , and fully stirred and dissolved to make a feed liquid;

[0028] (2) Heating the gel: heat the material liquid in step (1) to 85°C, keep it warm for 15 minutes, then add 0.3 parts by weight of gluconolactone, stir evenly and control the temperature at 85°C for 30 minutes, then take it out and cool it to 60°C, made into a gel;

[002...

Embodiment 2

[0034] The components of the soybean protein curd product contain (parts by weight): isolated soybean protein 5.5, whole milk powder 1, skim milk powder 4, white sugar 5, aspartame 0.01, gluconolactone 0.25, carboxymethyl Base cellulose sodium 0.15, xanthan gum 0.05, peach flavor 0.06, apricot flavor 0.04, peach jam 5, apricot jam 3, water 76.

[0035] The preparation method of the soybean protein curd product comprises the following steps:

[0036] (1) Mixing: Mix 5.5 parts by weight of soybean protein isolate, 1 part by weight of whole milk powder, 4 parts by weight of skimmed milk powder, 5 parts by weight of white sugar, and 0.01 part by weight of aspartame, and then add 76 parts by weight of water part, and fully stirred and dissolved to make a feed liquid;

[0037] (2) Heating the gel: heat the material liquid in step (1) to 95°C, keep it warm for 3 minutes, then add 0.25 parts by weight of gluconolactone, stir evenly and control the temperature at 85°C for 30 minutes, ...

Embodiment 3

[0043] The components of the soybean protein curd product contain (parts by weight): isolated soybean protein 5.5, whole milk powder 1, skim milk powder 2, sucralose 0.001, neotame 0.001, gluconolactone 0.2, carboxymethyl Sodium cellulose 0.1, konjac gum 0.05, milk flavor 0.15, chocolate sauce 5, water 86.

[0044] The preparation steps of the soybean protein curd product are as follows:

[0045] (1) Mixing: Mix 5.5 parts by weight of soybean protein isolate, 1 part by weight of whole milk powder, 2 parts by weight of skimmed milk powder, 0.001 part by weight of sucralose, and 0.001 part by weight of neotame, then add 86 parts by weight of water , and fully stirred and dissolved to make a feed liquid;

[0046](2) Heating the gel: heat the material liquid in step (1) to 85°C, keep it warm for 15 minutes, then add 0.2 parts by weight of gluconolactone, stir evenly and control the temperature at 85°C for 30 minutes, then take it out and cool it to 60°C, made into a gel;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com