Single-dispersity and opposite-polarity Janus gel microsphere with core-shell structure, preparation method and microfluid control device used

A technology of polar anisotropy and core-shell structure, which is applied in the preparation of microspheres, microcapsule preparations, chemical instruments and methods, etc., to achieve the effects of uniform particle size, easy assembly and disassembly, and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

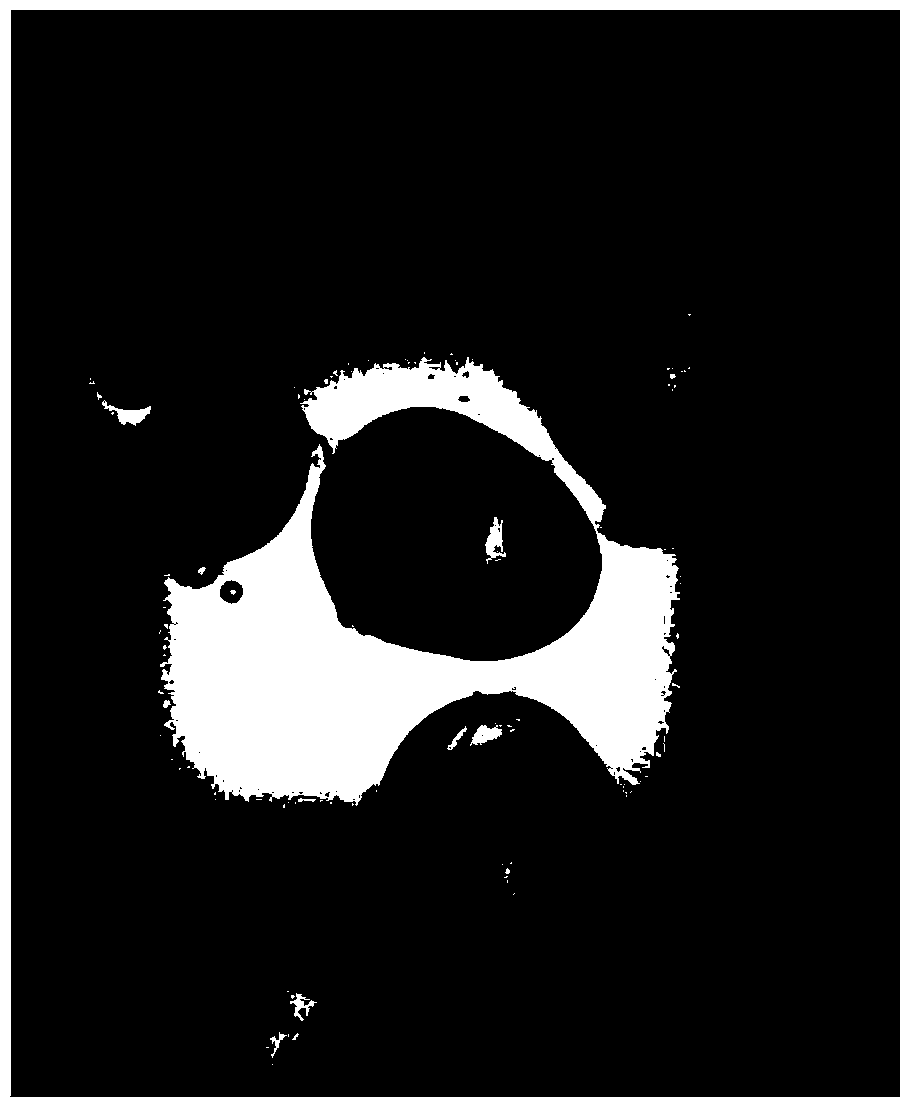

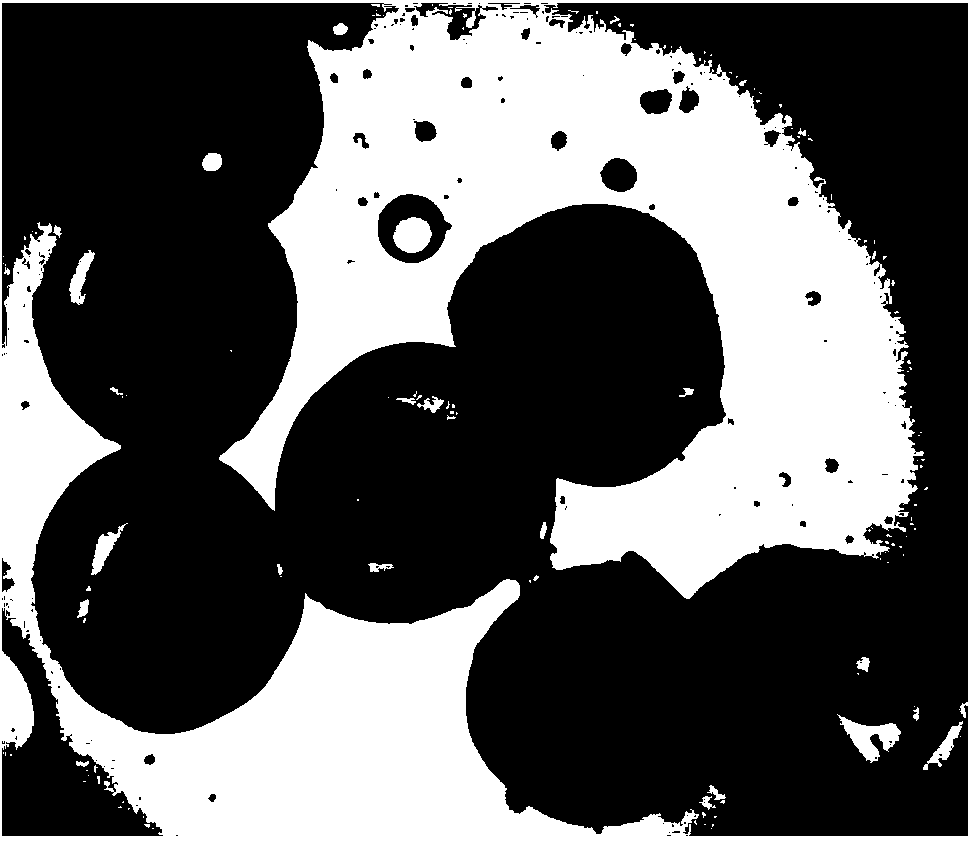

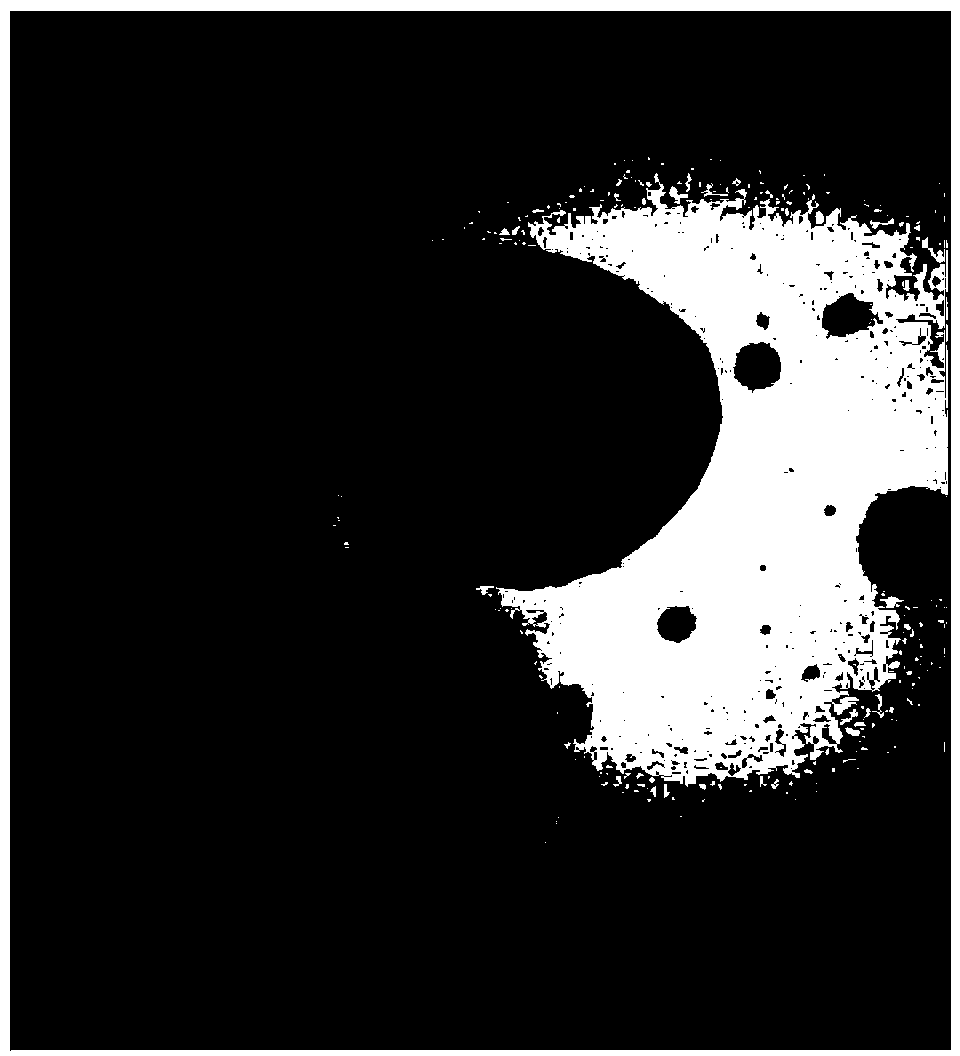

Image

Examples

Embodiment 1

[0049] Mix 19.2g TPGDA and 0.8g HCPK, dissolve with magnetic stirring, and make a non-polar dispersed phase solution.

[0050] Take 2g of acrylamide, 0.3g of bisacrylamide, 0.1g of ammonium persulfate, mix them, add 0.1g of sodium dodecylbenzenesulfonate (SDBS), add water to 20g, stir and dissolve with magnetic force, and make polar dispersions respectively. phase solution and polar nucleation phase solution.

[0051] The above-mentioned polar dispersed phase solution, polar nucleation phase solution and non-polar dispersed phase solution were respectively filled into 1 mL syringes, placed on corresponding syringe pumps, and connected to microfluidic control devices. Then take simethicone as the continuous phase solution and place it in a 20mL continuous phase syringe, install it on the continuous phase syringe pump, and connect it to the microfluidic control device. Set the flow rate of the polar dispersed phase solution to 2 μL min-1, the flow rate of the non-polar disperse...

Embodiment 2

[0054] Mix 19.2g TPGDA and 0.8g HCPK, dissolve with magnetic stirring, and make a non-polar dispersed phase solution.

[0055] Take 2g of acrylamide, 0.3g of bisacrylamide, 0.1g of ammonium persulfate, mix them, add 0.1g of sodium dodecylbenzenesulfonate (SDBS), add water to 20g, stir and dissolve with magnetic force, and make polar dispersions respectively. phase solution and polar nucleation phase solution.

[0056] The above-mentioned polar dispersed phase solution, polar nucleation phase solution and non-polar dispersed phase solution were respectively filled into 1 mL syringes, placed on corresponding syringe pumps, and connected to microfluidic control devices. Then take simethicone as the continuous phase solution and place it in a 20mL continuous phase syringe, install it on the continuous phase syringe pump, and connect it to the microfluidic control device. Set the flow rate of the polar dispersed phase solution to 2 μL min-1, the flow rate of the non-polar disperse...

Embodiment 3

[0059] Mix 19.2g TPGDA and 0.8g HCPK, dissolve with magnetic stirring, and make a non-polar dispersed phase solution.

[0060] Take 2g of acrylamide, 0.3g of bisacrylamide, 0.1g of ammonium persulfate, mix them, add 0.1g of sodium dodecylbenzenesulfonate (SDBS), add water to 20g, stir and dissolve with magnetic force, and make polar dispersions respectively. phase solution and polar nucleation phase solution.

[0061] The above-mentioned polar dispersed phase solution, polar nucleation phase solution and non-polar dispersed phase solution were respectively filled into 1 mL syringes, placed on corresponding syringe pumps, and connected to microfluidic control devices. Then take simethicone as the continuous phase solution and place it in a 20mL continuous phase syringe, install it on the continuous phase syringe pump, and connect it to the microfluidic control device. Set the flow rate of the polar dispersed phase solution to 2 μL min-1, the flow rate of the non-polar disperse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com