Intelligent control system of hydraulic gyratory crusher

A control system and gyratory breaking technology, applied in grain processing and other directions, can solve problems such as lack of comprehensive consideration, and achieve the effect of improving use efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

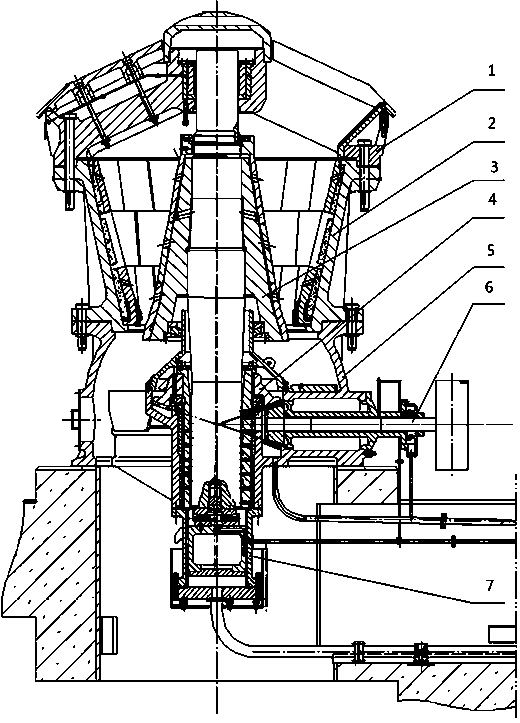

[0026] The hydraulic gyratory crusher consists of a beam part 1, a middle frame body 2, a crushing cone part 3, an eccentric sleeve 4, a base part 5, a base part 6, and a hydraulic transmission part 7, such as figure 1 shown. The original drive, oil cylinder, hydraulic pressure, pulley, electrical and dry, thin oil lubrication and other parts, such as figure 1shown. The motor is driven by the belt pulley and the bevel gear to make the crushing cone and the center line of the crusher do a pendulum motion, and the surface of the crushing cone approaches and leaves the surface of the fixed cone from time to time, so that the ore fed into the crushing chamber is continuously squeezed And the bending action surface is crushed, and the crushed ore is discharged from the bottom of the crushing chamber by its own weight.

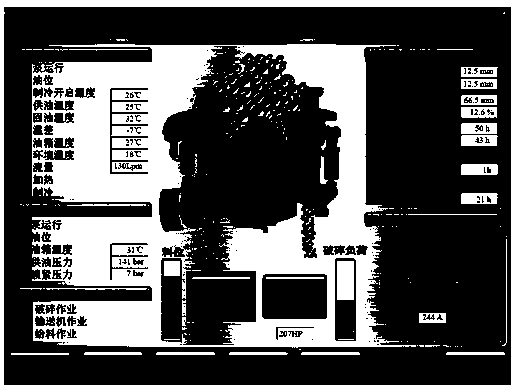

[0027] Hydraulic intelligent control system: The pressure sensor is used to monitor the pressure of the hydraulic system in real time, the displacement sensor is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com