A method for laser coordinated bending of metal laminates

A technology of laminates and metal layers, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of forming accuracy and quality difficult to accurately control, limit the carrying capacity of high-end equipment, failure and other problems, to improve the laser bending forming The effect of precision and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

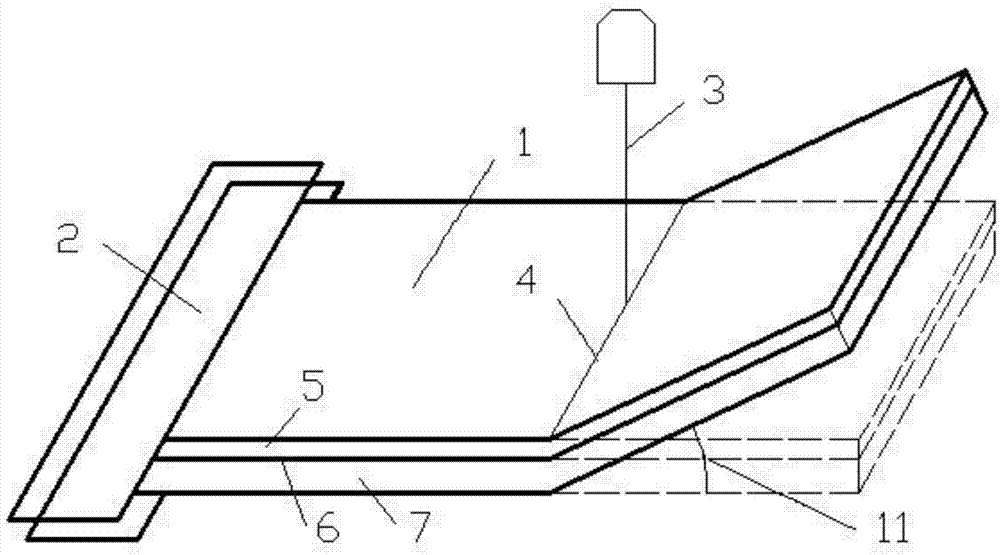

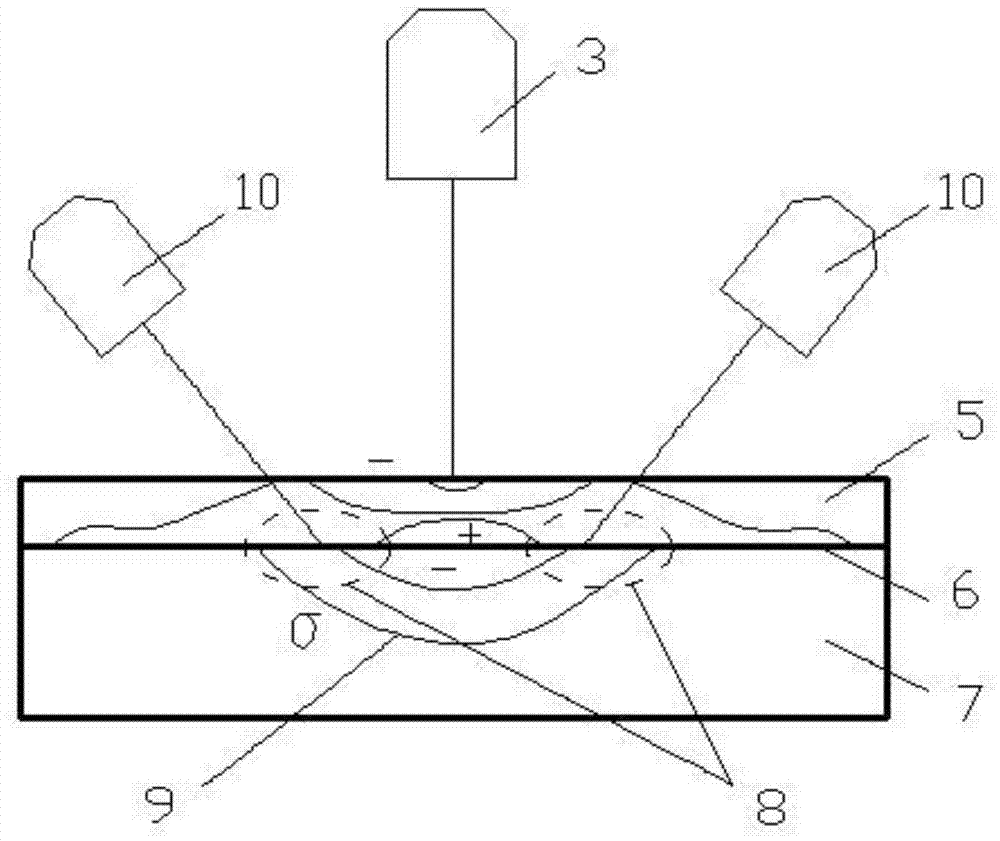

[0012] Aiming at the heating and bending forming of grooved bulkheads of metal laminates, the coordinated bending forming method is used in the laser heating and bending of metal laminates, and the laser energy input, transfer process and control method that can describe the metal laminates are established. The laser energy mode is superimposed and transformed to suppress the sudden change of the internal stress of the metal laminate when the laser is bent, to prevent local wrinkling, cracking, expansion and peeling of the joint surface, and to obtain the shape of the plate that meets the engineering technical requirements. Its detailed implementation is as follows:

[0013] There are many combinations of metal laminate materials that can be used for bending forming, such as stainless steel-carbon steel laminates, titanium alloy-carbon steel laminates, aluminum alloy-carbon steel laminates, etc. There are also various combinations and preparations of laminates , can be a doubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com