An ultrasonic-assisted DC resistance brazing aluminum alloy method

A DC resistance, ultrasonic-assisted technology, used in welding equipment, metal processing equipment, welding/welding/cutting items, etc., can solve problems such as blasting, affecting the formation of welded joints, and inability to provide large currents to increase energy. Input, ensure grain refinement, reduce the effect of heat affected zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

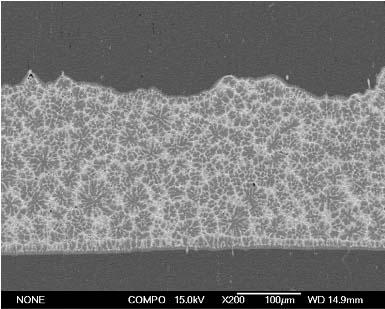

Image

Examples

specific Embodiment

[0031] The following are specific embodiments of the present invention, including the following steps:

[0032] one. Preparation before welding:

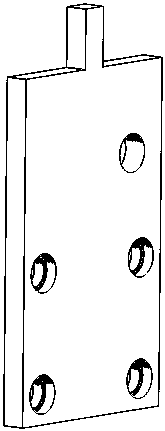

[0033] Before welding, process a 6mm×8mm arc groove with a depth of 0.15mm at the joint of the lower workpiece, and polish the surface of the upper and lower workpieces to be welded to remove the continuous and dense oxide film on the aluminum alloy surface, and then wipe it with cotton dipped in acetone solution Remove grease and other impurities on the surface of the workpiece to be welded, and then clean the surface of the workpiece to be welded with absolute ethanol to remove residual acetone solution; combine the previous practical experience and existing equipment, install the upper and lower workpieces on the existing insulating sliding device, Use bolts and insulating caps to connect the assembly holes on the base metal and the positioning holes of the upper insulation, lower insulation plate, upper slide plate, and lower p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com