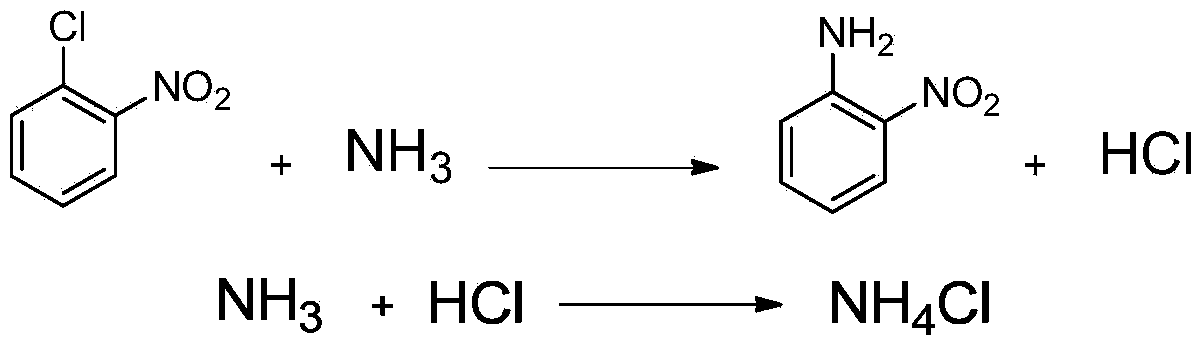

Method for preparing ortho-nitroaniline by high pressure ammonolysis

A technology for o-nitroaniline and o-chloronitrobenzene, applied in the field of preparing o-nitroaniline, can solve the problems of complex production operation, many reaction steps, few industrialized production and the like, and achieves low production cost, simple operation, good quality The effect of industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 800g of o-chloronitrobenzene and 300g of liquid ammonia to a 2L autoclave, raise the temperature to 170°C, press at 8MPa, keep at 170°C for 7 hours, cool down, recover excess liquid ammonia, then add 1000g of toluene into the reaction kettle, and stir for 15 Minutes later, it was filtered, and the obtained filtrate was distilled to recover the solvent to obtain 681 g of o-nitroaniline with a gas chromatography purity of 99.5% and a molar yield of 97.1%.

Embodiment 2

[0024] Add 800g of o-chloronitrobenzene and 480g of liquid ammonia to a 2L autoclave, raise the temperature to 150°C, press at 10MPa, keep at 150°C for 15 hours, cool down, recover excess liquid ammonia, and then add 1000g of dichloroethane into the reaction kettle , after stirring for 15 minutes, filtered, and the obtained filtrate was distilled to recover the solvent to obtain 683g of o-nitroaniline, with a gas chromatography purity of 99.6% and a molar yield of 97.4%.

Embodiment 3

[0026] Add 800g of o-chloronitrobenzene and 240g of liquid ammonia to a 2L autoclave, raise the temperature to 200°C, and the pressure is 7.5MPa, keep at 200°C for 11 hours, cool down, recover excess liquid ammonia, then add 1000g of toluene into the reaction kettle, stir After 15 minutes, it was filtered, and the obtained filtrate was distilled to recover the solvent to obtain 675 g of o-nitroaniline with a gas chromatography purity of 99.2% and a molar yield of 96.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com