Citric acid and rare earth complex as well as preparation method and application of rare earth catalyst

A rare-earth citric acid and rare-earth catalyst technology, applied in the field of rare-earth catalysts and their preparation, and rare-earth citric acid complexes, to achieve the effects of easy transportation, low price, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

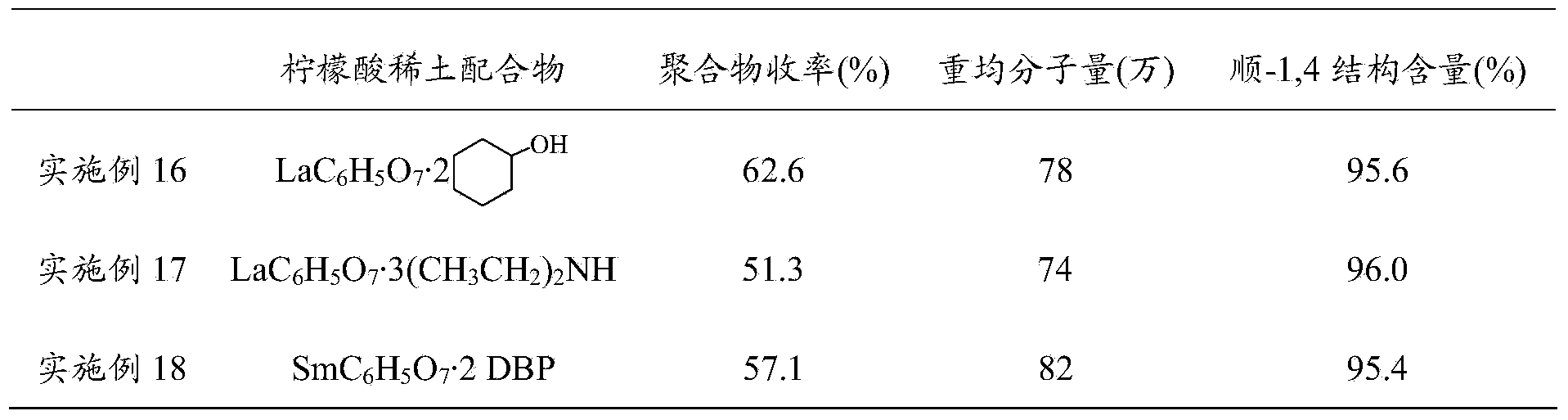

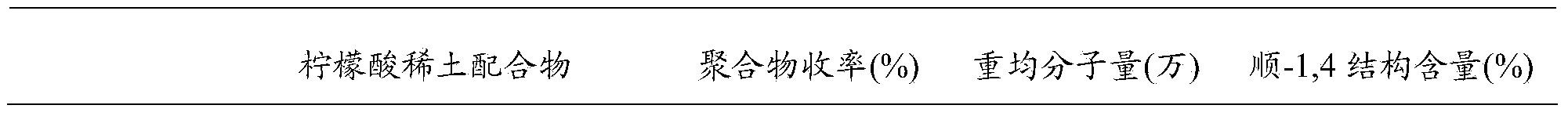

Examples

preparation example Construction

[0027] The present invention also provides a kind of preparation method of rare earth citrate complex, comprising the following steps:

[0028] The citrate rare earth compound and the electron-donating ligand are mixed in the first organic solvent, heated to carry out a reflux reaction, and the citrate rare earth complex is obtained after the first organic solvent is removed.

[0029] Wherein, the present invention has no special limitation on the sources of all raw materials, which can be commercially available or self-made.

[0030] The rare earth citrate compound is preferably prepared according to the following method: mixing the alcoholic aqueous solution of citric acid and the alcoholic aqueous solution of rare earth chloride to obtain a mixed solution, adjusting the pH value of the mixed solution to be alkaline, and filtering to obtain the rare earth citrate compound.

[0031] The invention mixes the alcoholic aqueous solution of citric acid and the alcoholic aqueous so...

Embodiment 1

[0048] 1.1 Dissolve citric acid and neodymium chloride in aqueous ethanol solution with a volume ratio of 1:1, and slowly drop the ethanol aqueous solution of neodymium chloride into the aqueous solution of citric acid and ethanol at a temperature of 50°C, and then drop them into the mixed solution. Add sodium hydroxide solution until the pH value is 4-5, and obtain a large amount of precipitate, filter, wash with absolute ethanol for 2-3 times, and dry to obtain a neodymium citrate compound.

[0049] 1.2 Add the neodymium citrate compound and isooctyl alcohol obtained in 1.1 into the reactor at a molar ratio of 1:3, then add 40ml of tetrahydrofuran as a solvent, condense and reflux for 5 to 24 hours in a boiling state, and evaporate the solvent. and dried to constant weight to obtain the rare earth citrate complex NdC 6 h 5 o 7 ·3(CH 3 ) 2 C(CH 2 ) 5 Oh.

Embodiment 2

[0051] Add the neodymium citrate compound and ethylamine obtained in 1.1 into the reactor at a molar ratio of 1:2, then add 20ml of tetrahydrofuran as a solvent, condense and reflux for 5 to 24 hours in a boiling state, evaporate the solvent, and dry to constant weight, the rare earth complex NdC of citrate was obtained 6 h 5 o 7 ·2CH 3 CH 2 NH 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com