Fluorine-containing polymer and preparation method thereof

A technology for polymers and monomers, applied in the field of fluorine-containing polymers and its preparation, can solve problems such as foaming or cracking, discoloration, unfavorable processing and application, and achieve high transparency, excellent tensile strength and heat resistance

Inactive Publication Date: 2014-06-18

SHANDONG HUAXIA SHENZHOU NEW MATERIAL

View PDF3 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Ethylene-tetrafluoroethylene (molar ratio 1:1) binary copolymer has a high melting point and is close to the thermal decomposition temperature. If the processing time is longer, it will cause discoloration, foaming or cracking, which is not conducive to processing and application; therefore, in order to improve Its thermal stability and mechanical properties at high temperature generally need to be modified, and a small amount of functional monomers are added according to special purposes to obtain certain characteristics

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

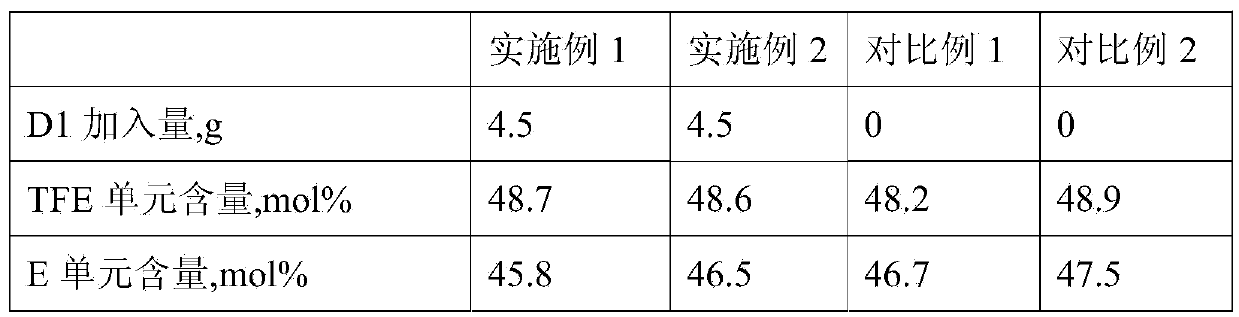

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

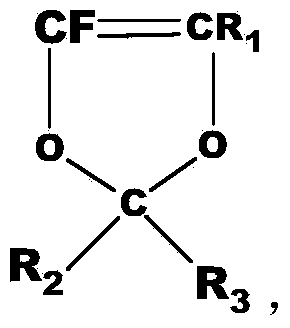

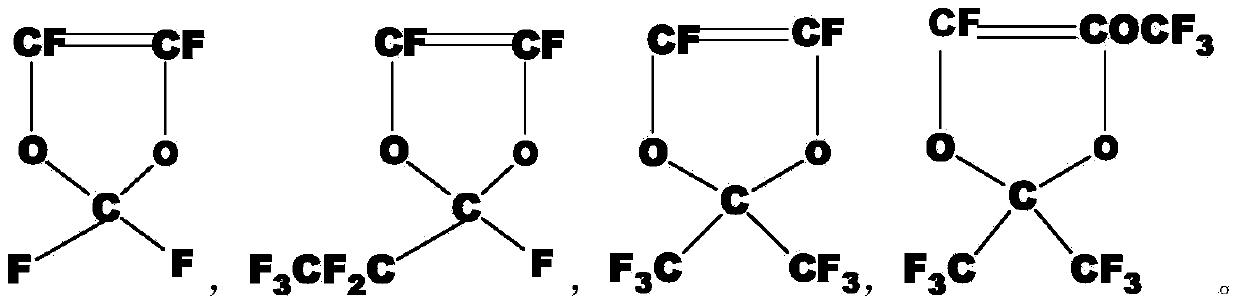

The invention belongs to the field of high molecular fluorine-containing materials, which relates to a fluorine-containing polymer and a preparation method thereof. The fluorine-containing polymer is polymerized of modified monomer units and polymerized monomer units, wherein each modified monomer is a perfluoroalkyl ether monomer containing fluorinated olefin or a perfluorinated oxygen heterocyclic monomer; and the molar ratio of the content of the modified monomer units to the content of all the monomer units is (0.01-10):100. In the preparation method, suspension polymerization or mixed phase polymerization or emulsion polymerization is adopted. The fluorine resin obtained by the preparation method is high in transparency and has excellent tensile strength, heat resistance and weather resistance. Thus, the fluorine-containing polymer is particularly suitable for architectural and agricultural greenhouse film materials as well as optical fiber and solar battery protection materials.

Description

technical field The invention belongs to the field of fluorine-containing polymer materials, and relates to a fluorine-containing polymer and a preparation method thereof. Background technique Fluoroplastic films are widely used due to their light weight, excellent weather resistance and mechanical strength. Taking ethylene-tetrafluoroethylene copolymer (ETFE) membrane as an example, the fluororesin film does not require fabric or glass fiber base layer, and has good processing performance. The modified ETFE resin can be processed by general flat membrane technology. Extruded into film, the film can be heat-sealed with a special heat-sealing machine. Due to its good tear resistance, the film can be sewn with threads that resist environmental changes. The maximum size of a single piece can reach 25m*3.5m. Glass size exceeding the largest panel (generally the largest is 8m 2 ), at the same time, ETFE resin has very good weather resistance, mechanical strength, light transmis...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08F214/26C08F214/28C08F210/02

Inventor 陈庆芬王汉利张永明张恒李星牛忠

Owner SHANDONG HUAXIA SHENZHOU NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com