Phenolic foam plate containing nanometer aerogel and production method of phenolic foam plate

A technology of phenolic foam board and nano airgel, applied in the preparation of phenolic foam board, the preparation of said phenolic foam board, the field of phenolic foam board containing nano airgel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

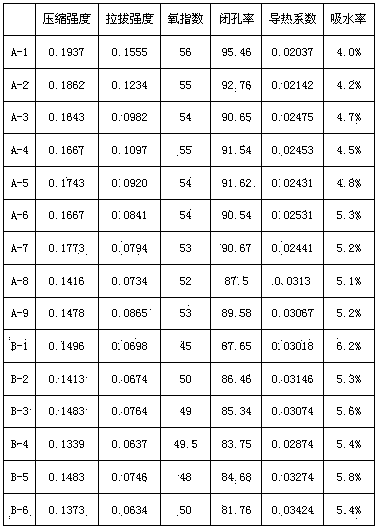

Examples

Embodiment 1

[0030] 100 parts by mass of phenolic resin, 8 parts by mass of isopentane, 5 parts by mass of castor oil polyoxyethylene ether, and 5 parts by mass of toughening agent (obtained by mixing polyvinylpyrrolidone and ethylene glycol at a mass ratio of 1:3.5) , 3 parts by mass of aluminum hydroxide, 3 parts by mass of nano-scale silica airgel filler and 20 parts by mass of curing agent (the curing agent is a mixed curing mixture of p-toluenesulfonic acid, phosphoric acid and sulfuric acid in a ratio of 5:3:2 agent) to stir and mix evenly, quickly pour it into a 32×32×4cm mold preheated at 65°C for foaming, and cure at 65°C for 10 minutes to obtain phenolic foam A-1, and its performance indicators are listed in Table 1.

Embodiment 2

[0032] 100 parts by mass of phenolic resin, 8 parts by mass of isopentane, 5 parts by mass of castor oil polyoxyethylene ether, and 5 parts by mass of toughening agent (obtained by mixing polyvinylpyrrolidone and ethylene glycol at a mass ratio of 1:3.5) , 3 parts by mass of aluminum hydroxide, 5 parts by mass of nano-scale silica airgel filler and 20 parts by mass of curing agent (the curing agent is a mixed curing agent mixed with p-toluenesulfonic acid, phosphoric acid and sulfuric acid in a ratio of 5:3:2 agent) to stir and mix evenly, quickly pour it into a preheated 65°C 32×32×4cm mold for foaming, and cure at 65°C for 10 minutes to obtain phenolic foam A-2, and its performance indicators are listed in Table 1.

Embodiment 3

[0034] 100 parts by mass of phenolic resin, 8 parts by mass of isopentane, 5 parts by mass of castor oil polyoxyethylene ether, and 5 parts by mass of toughening agent (obtained by mixing polyvinylpyrrolidone and ethylene glycol at a mass ratio of 1:3.5) , 3 parts by mass of aluminum hydroxide, 1 part by mass of nano-scale silica airgel filler and 20 parts by mass of curing agent (the curing agent is a mixed curing mixture of p-toluenesulfonic acid, phosphoric acid and sulfuric acid in a ratio of 5:3:2 agent) to stir and mix evenly, quickly pour it into a 32×32×4cm mold preheated at 65°C to foam, and cure at 65°C for 10 minutes to obtain phenolic foam A-3, and its performance indicators are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com