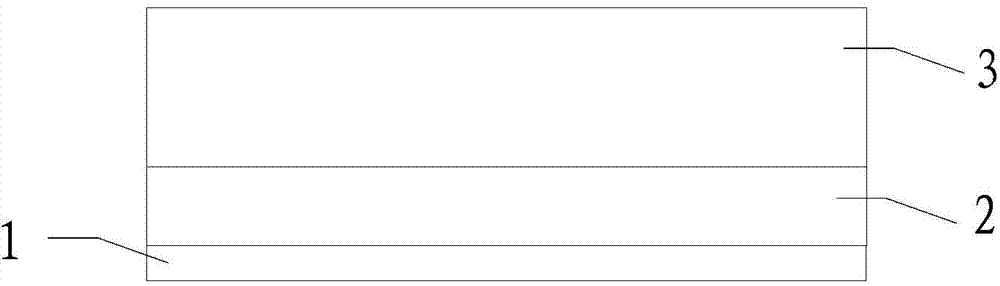

High-carrier concentration ultrathin AZO transparent conducting thin film and preparation method thereof

A transparent conductive film, high carrier technology, applied in the conductive layer on the insulating carrier, ion implantation plating, coating, etc., can solve the problem of low carrier concentration of ultra-thin AZO film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

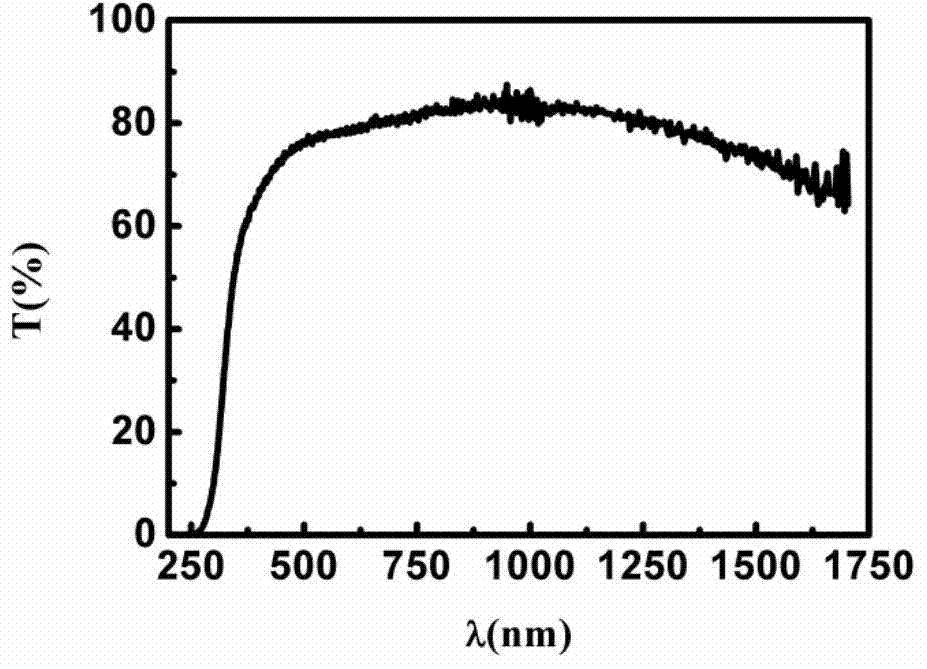

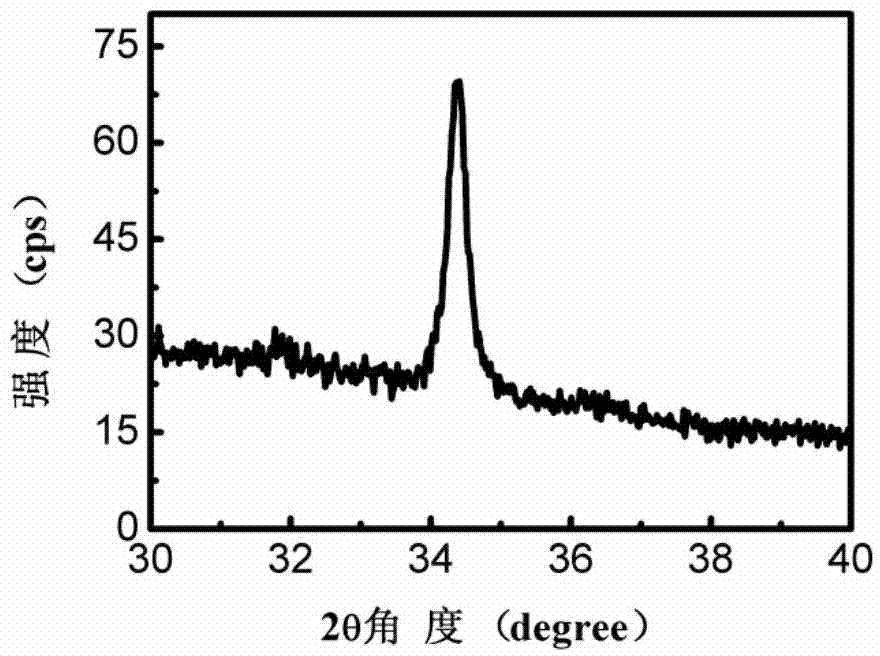

Embodiment 1

[0053] Aluminum oxide (Al 2 o 3 ) and zinc oxide (ZnO) with a mass ratio of Al 2 o 3 :ZnO=2:98 self-made AZO ceramic target (ie Al 2 o 3 AZO ceramic target with a mass percentage of 2%), and a commercial zinc (Zn) metal target with a purity of 99.99%, which are loaded into the vacuum chamber of the ultra-high vacuum magnetron sputtering equipment;

[0054] Select the ultra-white glass substrate as the substrate. After the usual cleaning conditions, the glass substrate is cleaned with ultraviolet ozone. The conditions for ultraviolet ozone cleaning are: the power of the VUV low-pressure ultraviolet mercury lamp is 60W, the treatment time is 1h, and the treatment temperature is 40°C, and then put it into the vacuum chamber of ultra-high vacuum magnetron sputtering equipment;

[0055] Use a mechanical pump and a molecular pump to evacuate the vacuum chamber, and keep the vacuum degree of the vacuum chamber (that is, the background vacuum degree) at 3.0×10 -4 Pa, do not heat...

Embodiment 2

[0063] Aluminum oxide (Al 2 o 3 ) and zinc oxide (ZnO) with a mass ratio of Al 2 o 3 :ZnO=2:98 self-made AZO ceramic target (ie Al 2 o 3 AZO ceramic target with a mass percentage of 2%), and a commercial Zn metal target with a purity of 99.99%, which are loaded into the vacuum chamber of the ultra-high vacuum magnetron sputtering equipment;

[0064] Select the ultra-clear glass substrate as the substrate. After the usual cleaning conditions, the glass substrate is cleaned with ultraviolet ozone. The conditions for ultraviolet ozone cleaning are: the power of the VUV low-pressure ultraviolet mercury lamp is 80W, the treatment time is 1.5h, and the treatment temperature 50°C, and then put it into the vacuum chamber of ultra-high vacuum magnetron sputtering equipment;

[0065] Use a mechanical pump and a molecular pump to evacuate the vacuum chamber, and keep the vacuum degree of the vacuum chamber (that is, the background vacuum degree) at 4.0×10 -4 Pa, heat the substrate ...

Embodiment 3

[0073] Aluminum oxide (Al 2 o 3 ) and zinc oxide (ZnO) with a mass ratio of Al 2 o 3 :ZnO=2:98 self-made AZO ceramic target (ie Al 2 o 3 AZO ceramic target with a mass percentage of 2%), and a commercial Zn metal target with a purity of 99.99%, which are loaded into the vacuum chamber of an ultra-high vacuum magnetron sputtering equipment;

[0074] Select the ultra-white glass substrate as the substrate. After the usual cleaning conditions, the glass substrate is cleaned with ultraviolet ozone. The conditions for ultraviolet ozone cleaning are: the power of the VUV low-pressure ultraviolet mercury lamp is 60W, the treatment time is 1.5h, and the treatment temperature 40°C, and then put it into the vacuum chamber of ultra-high vacuum magnetron sputtering equipment;

[0075] Use a mechanical pump and a molecular pump to evacuate the vacuum chamber, and keep the vacuum degree of the vacuum chamber (that is, the background vacuum degree) at 2.0×10 -4 Pa, the substrate is hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com