Preparation method and application of tri-(2, 3-dibromopropyl) isocyanurate sensor

A technology of isocyanurate and dibromopropyl, applied in the preparation and application field of tris-(2,3-dibromopropyl) isocyanurate sensor, can solve the low selectivity of electrochemiluminescence , liquid chromatography tandem mass spectrometry equipment expensive and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Pretreatment of working electrode:

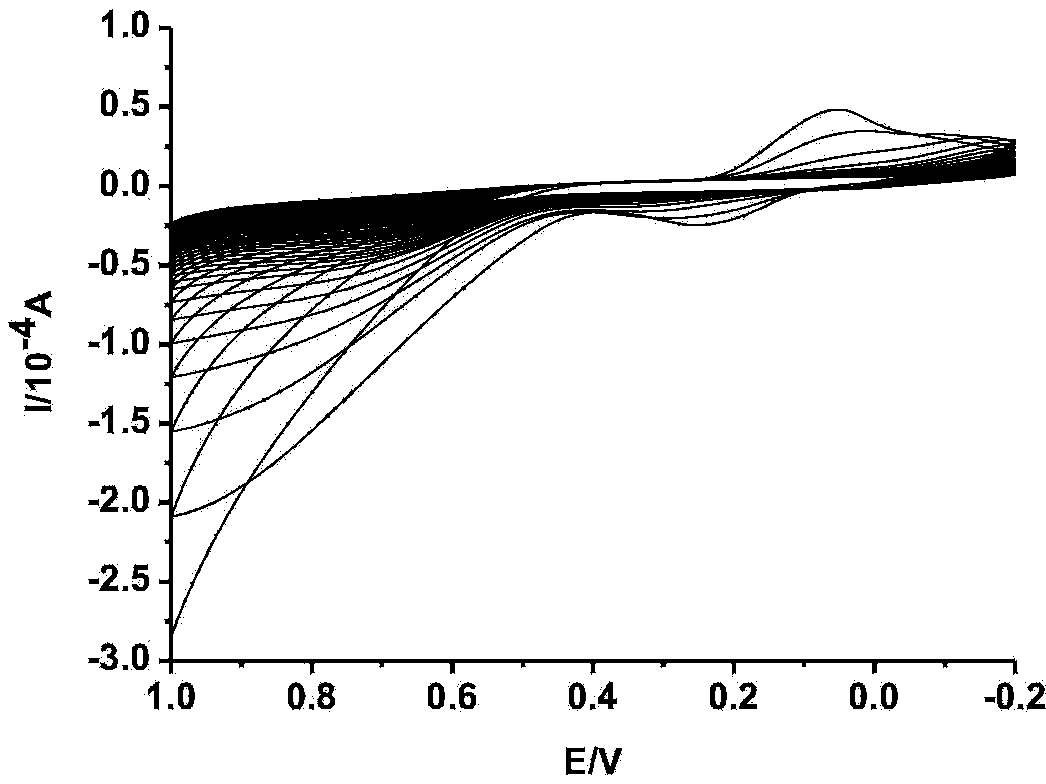

[0039] Polish the glassy carbon electrode on alumina slurry with a particle size of 0.3μm and 0.05μm until a smooth mirror surface appears, and then use dilute HNO 3 (Volume ratio is 1:1), ultrasonic cleaning with absolute ethanol and distilled water, repeat 3 times, 3min each time. Then carry out electrochemical activation treatment [that is, at 0.5mol / L H 2 SO 4 Perform a cyclic voltammetry scan at -0.3~1.5V] until a stable cyclic voltammetry response curve is obtained.

[0040] Preparation of the blot sensor:

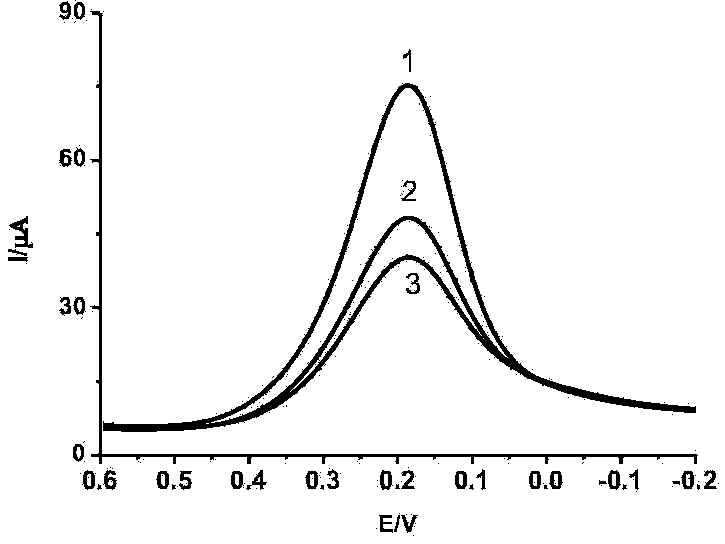

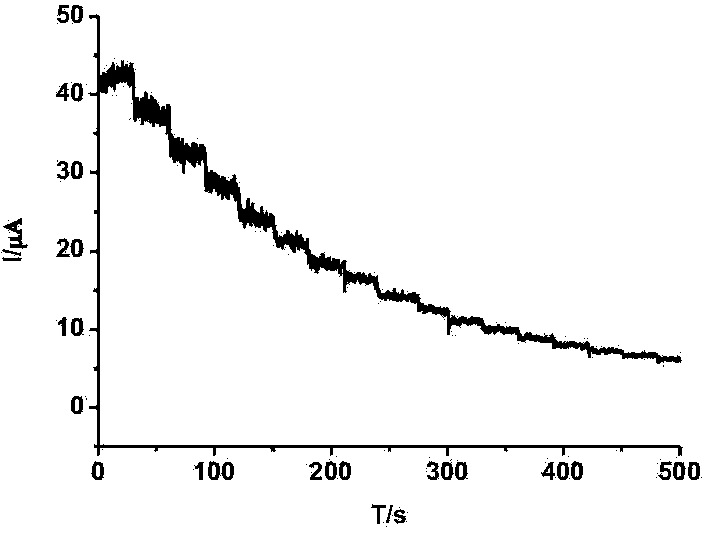

[0041] Dissolve 0.0136g o-aminophenol in 0.1mol / L HClO 4 In the medium, adjust the pH with 0.4mol / L NaOH to make it weakly acidic, and dilute to 50mL. Add 20mL o-aminophenol solution and 10mL1.0×10 to the electrolytic cell -4 mol / L tris-(2,3-dibromopropyl) isocyanurate solution. The treated glassy carbon electrode is used as the working electrode, the platinum wire electrode is the auxiliary electrode, the saturated Ag / AgCl elec...

Embodiment 2

[0045] Pretreatment of working electrode:

[0046] Polish the gold electrode on the suede containing the alumina slurry with a particle size of 0.03μm for 5min, and then place it on the V 30%H2O2 :V Concentrated H2SO4 Soak in a solution of 1:3 for 10 minutes, and wash with twice distilled water and absolute ethanol for 5 minutes each ultrasonically to remove the alumina and other impurities adsorbed on the electrode surface, and then at 1.0mol / L H 2 SO 4 Carry out cyclic voltammetry scanning in the potential range of -0.20~+1.40V in the solution until a stable cyclic voltammetry response is obtained.

[0047] Preparation of the blot sensor:

[0048] Dissolve 0.0500g 2-mercaptobenzimidazole in 30mL ethanol, and the solution is mixed with 8mL1.0×10 -3 Mix the mol / L tris-(2,3-dibromopropyl) isocyanurate solution and deoxygenate with nitrogen for 5 min. The treated gold electrode is used as the working electrode, the platinum wire electrode is the auxiliary electrode, the saturated Ag...

Embodiment 3

[0052] Pretreatment of working electrode:

[0053] Polish the glassy carbon electrode on alumina slurry with a particle size of 0.3μm and 0.05μm until a smooth mirror surface appears, and then use dilute HNO 3 (Volume ratio is 1:1), ultrasonic cleaning with absolute ethanol and distilled water, repeat 3 times, 3min each time. Then carry out electrochemical activation treatment [that is, at 0.5mol / L H 2 SO 4 Perform a cyclic voltammetry scan at -0.3~1.5V] until a stable cyclic voltammetry response curve is obtained.

[0054] Preparation of the blot sensor:

[0055] 30mL of a mixture containing 0.0117g of tetrabutylammonium perchlorate and 0.0324g of o-aminothiophenol was passed through 99% nitrogen to deoxygenate for 5 minutes, and the pretreated glassy carbon electrode was self-assembled in this solution for 4 hours. Then, add 15mL0.5×10 to this solution - 3 mol / L tris-(2,3-dibromopropyl) isocyanurate solution to prepare polymerization solution. The treated glassy carbon electrode ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com