Aqueous polyaniline hollow microballoon and preparation method thereof

A water-based polyaniline and microsphere technology, applied in the preparation of microspheres, microcapsule preparations, etc., can solve problems such as pollution of the environment, and achieve the effects of low cost, good water dispersibility, and excellent hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of water-based polyaniline hollow microspheres comprises the following steps:

[0029] Step a) dissolving aniline and sulfoaniline in water to obtain an aqueous dispersion;

[0030] Step b) dissolving potassium ferricyanide in water to obtain an aqueous solution of potassium ferricyanide;

[0031] Step c) mixing the aqueous dispersion with an aqueous solution of potassium ferricyanide, reacting, and filtering to obtain a reaction product;

[0032] Step d) drying the reaction product obtained in step c) to obtain water-based polyaniline hollow microspheres.

[0033] In the preparation method of the present invention, preferably, the amount of aniline used is 95 parts by weight, the amount of sulfoaniline used is 87-118 parts by weight, and the amount of potassium ferricyanide used is 481-3290 parts by weight.

[0034] In the preparation method of the present invention, preferably, the mass percent concentration of aniline in the aqueous dispersio...

Embodiment 1

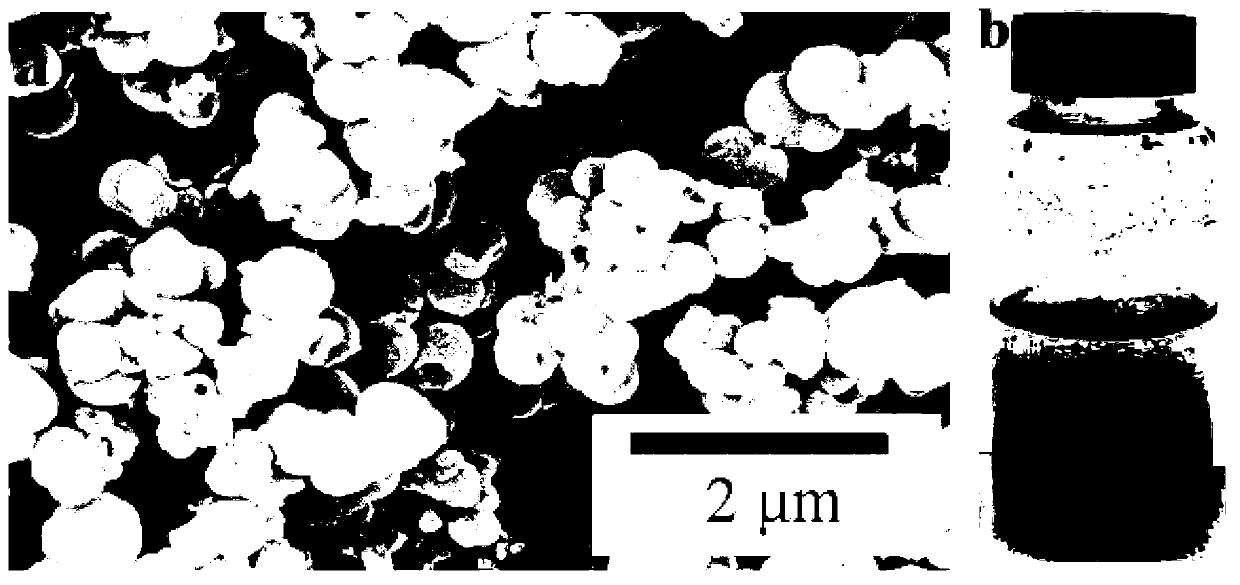

[0056] to combine figure 2 and image 3 Illustrative Example 1

[0057] Preparation of water-based polyaniline hollow microspheres:

[0058] Step a) dissolving 95g of aniline and 87g of 2-aminobenzenesulfonic acid in 120ml of water to obtain an aqueous dispersion;

[0059] Step b) dissolving the potassium ferricyanide of 1481g in 680ml water to obtain an aqueous solution of potassium ferricyanide;

[0060] Step c) mixing the aqueous dispersion with the potassium ferricyanide aqueous solution, standing still at -20°C for 20 hours, then filtering, washing with methanol, water, and methanol in sequence until the filtrate is colorless, and the reaction product is obtained;

[0061] Step d) vacuum drying the reaction product for 24 hours to obtain water-based polyaniline hollow microspheres.

[0062] figure 2 The scanning electron microscope pictures of the water-based polyaniline hollow microspheres prepared in Example 1 of the present invention and the dispersion of the wa...

Embodiment 2

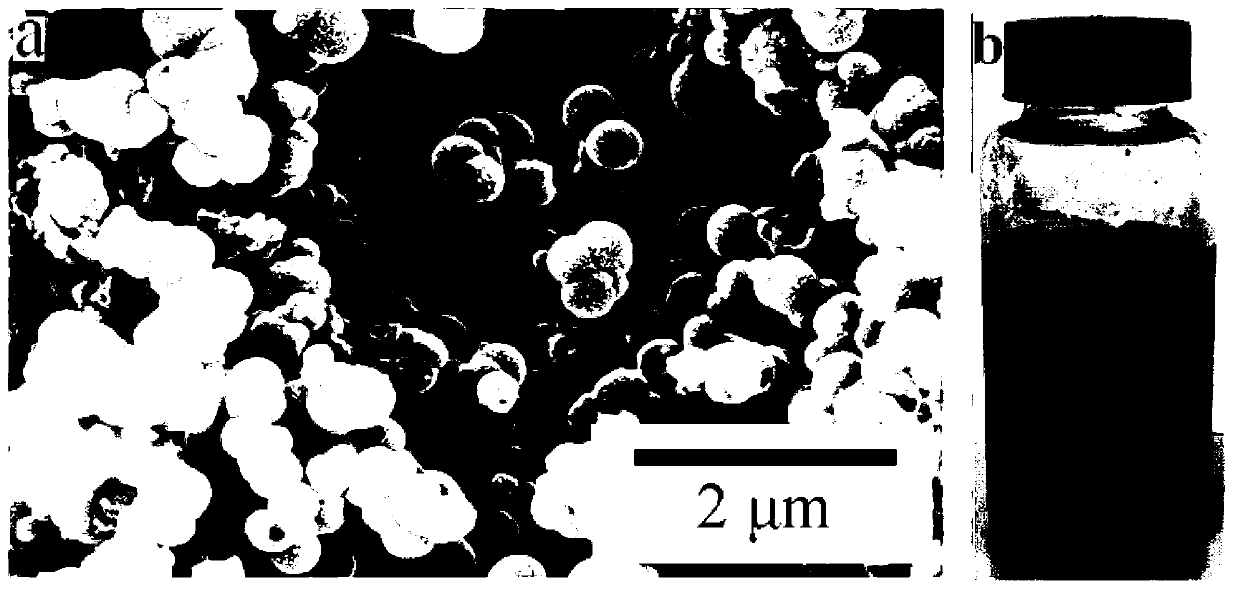

[0065] to combine Figure 4 and Figure 5 Illustrative Example 2

[0066] Preparation of water-based polyaniline hollow microspheres:

[0067] Step a) dissolving 95g of aniline and 118g of 4-acetamido-2-aminobenzenesulfonic acid in 235ml of water to obtain an aqueous dispersion;

[0068] Step b) dissolving 3290g of potassium ferricyanide in 1300ml water to obtain potassium ferricyanide aqueous solution;

[0069] Step c) mixing the aqueous dispersion with an aqueous solution of potassium ferricyanide, standing still at a temperature of 15°C for 48 hours, then filtering, washing with methanol, water, and methanol in sequence until the filtrate is colorless, and a reaction product is obtained;

[0070] Step d) vacuum drying the reaction product for 72 hours to obtain water-based polyaniline hollow microspheres.

[0071] Figure 4 The scanning electron microscope pictures of the water-based polyaniline hollow microspheres prepared in Example 2 of the present invention and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com