Process for producing ketone-free transferring card paper

A process and cardboard technology, used in the production of ketone-free transfer cardboard, can solve problems such as destroying the viscosity of the coating, affecting the coating process, and coating diffusion, and achieving the effects of preventing coating layering, avoiding direct contact, and improving uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

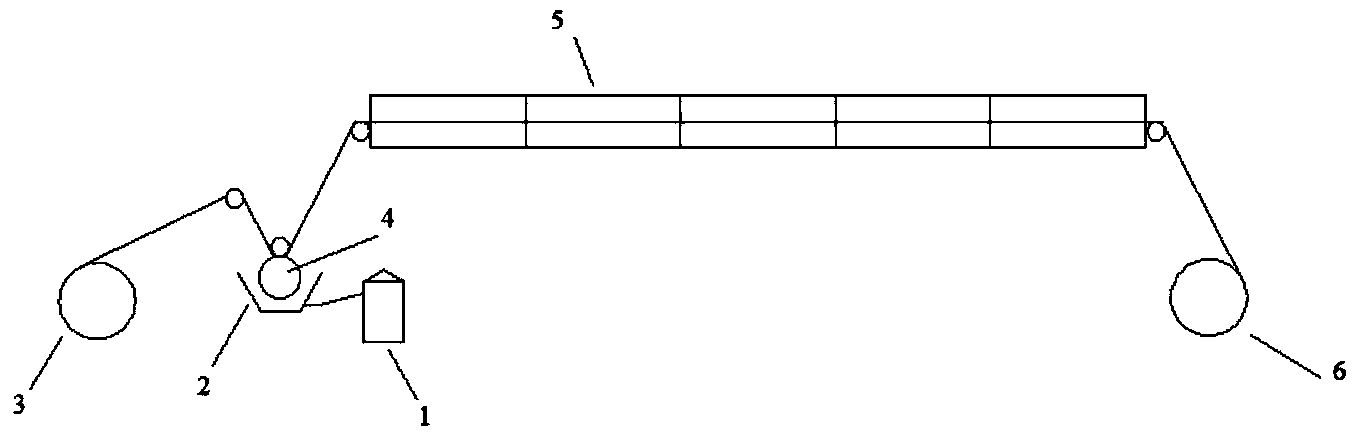

Method used

Image

Examples

Embodiment 1

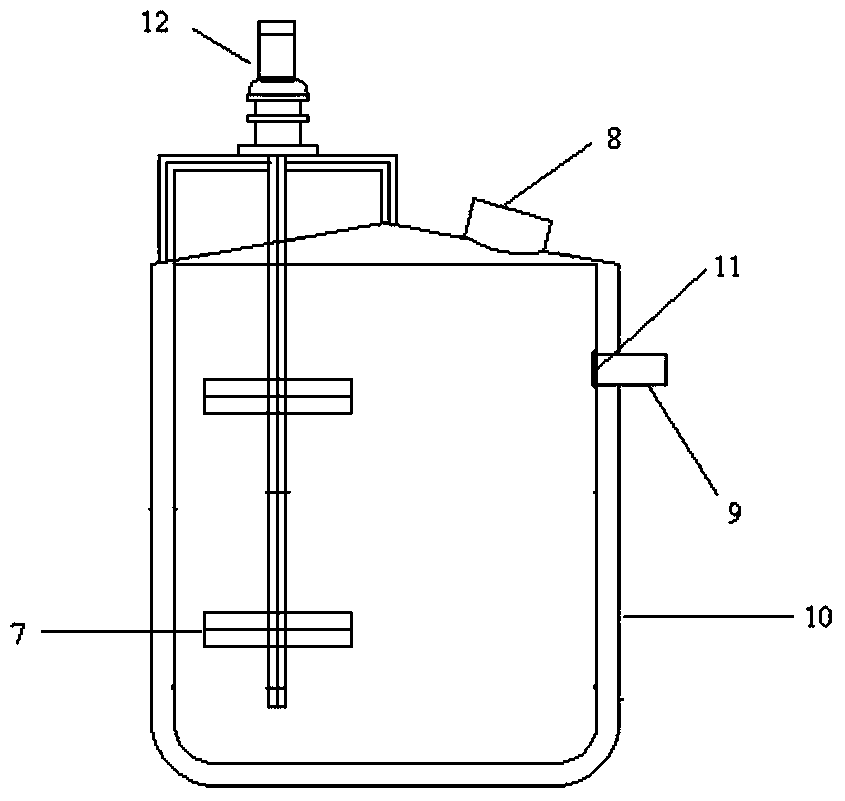

[0035] Configure water-based ketone-removing paint, polyacrylic acid 72%, water 20.5%, ethanolamine 1.5%, glacial acetic acid 1%, defoamer Foamex902W2%, wetting and dispersing agent Dispers7401%, preservative 02A2%.

[0036] The water-based ketone-removing paint enters the feeding tank through the vacuum feeding system. The constant temperature of the feeding tank is 25°C, the ambient temperature is 28°C, and the ambient humidity is 35%RH.

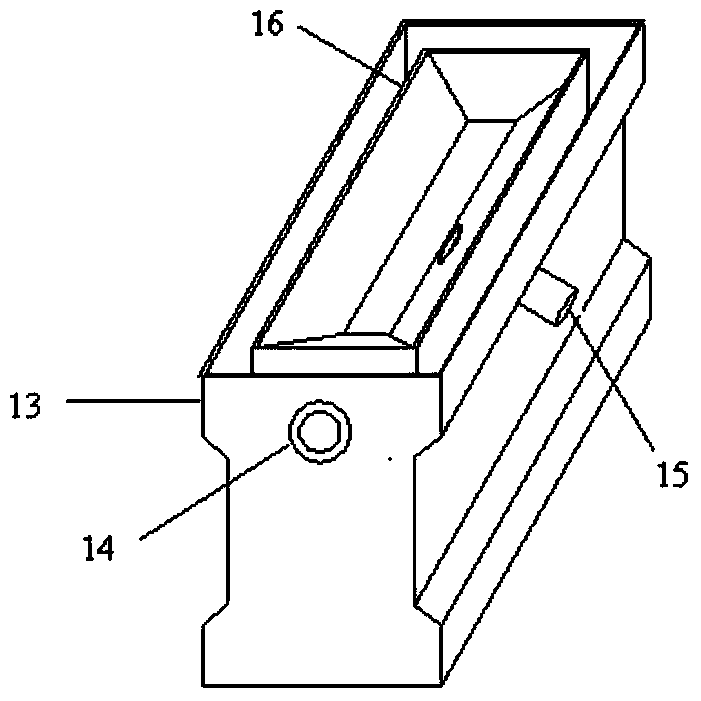

[0037] The water-based ketone-removing coating is coated on the white base paper card through an anilox roller, the mesh number of the anilox roller is 200 mesh, the cell opening on the surface of the anilox roller is hexagonal, the cell depth is 30μm, and the cardboard conveying speed is 135M / min, scraper pressure 1.5kg / cm 2 , the scraper is set in the 40° angle of the tangent to the radial section of the anilox roll.

[0038] The coated white card base paper is conveyed into the drying system, and the temperature field from the cardboa...

Embodiment 2

[0042] Configuration water-based ketone-removing paint, polymethyl methacrylate 62.5%, water 32.1%, ethanolamine 1%, glacial acetic acid 0.65%, defoamer Foamex8221.5%, wetting and dispersing agent RAD23000.75%, preservative 02B1.5 %.

[0043] The water-based ketone-removing paint enters the feeding tank through the vacuum feeding system. The constant temperature of the feeding tank is 25°C, the ambient temperature is 30°C, and the ambient humidity is 38%RH.

[0044] The water-based ketone-removing coating is coated on the white base paper card through an anilox roller, the mesh number of the anilox roller is 200 mesh, the cell opening on the surface of the anilox roller is hexagonal, and the cell depth is 35μm. The cardboard conveying speed is 145M / min, scraper pressure 2kg / cm 2 , the scraper is set in the 35° angle direction of the tangent to the radial section of the anilox roll.

[0045] The coated white card base paper is conveyed into the drying system, and the tempera...

Embodiment 3

[0049] Configuration water-based ketone-removing paint, methacrylic acid / butyl acrylate / acrylic acid copolymer 53%, water 43%, ethanolamine 0.75%, glacial acetic acid 0.5%, defoamer Foamex822 1.25%, wetting and dispersing agent Dispers7400.5%, Preservative 02C1%.

[0050] The water-based ketone-removing paint enters the feeding tank through the vacuum feeding system. The constant temperature of the feeding tank is 24°C, the ambient temperature is 35°C, and the ambient humidity is 45%RH.

[0051] The water-based ketone-removing coating is coated on the white base paper card through an anilox roller, the mesh number of the anilox roller is 200 mesh, the cell opening on the surface of the anilox roller is hexagonal, and the cell depth is 33μm. The cardboard conveying speed is 140M / min, scraper pressure 3kg / cm 2 , the scraper is set in the 30° angle direction of the tangent to the radial section of the anilox roll.

[0052] The coated white cardboard base paper is conveyed into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com