Device and method for online detecting oxygen and carbon dioxide in biological fermentation tail gas

A carbon dioxide and bio-fermentation technology, which is applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems that the installation method is not suitable for fermentation engineering production, less online detection equipment, complex operation and maintenance, etc., and achieve simple assembly , long service life and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

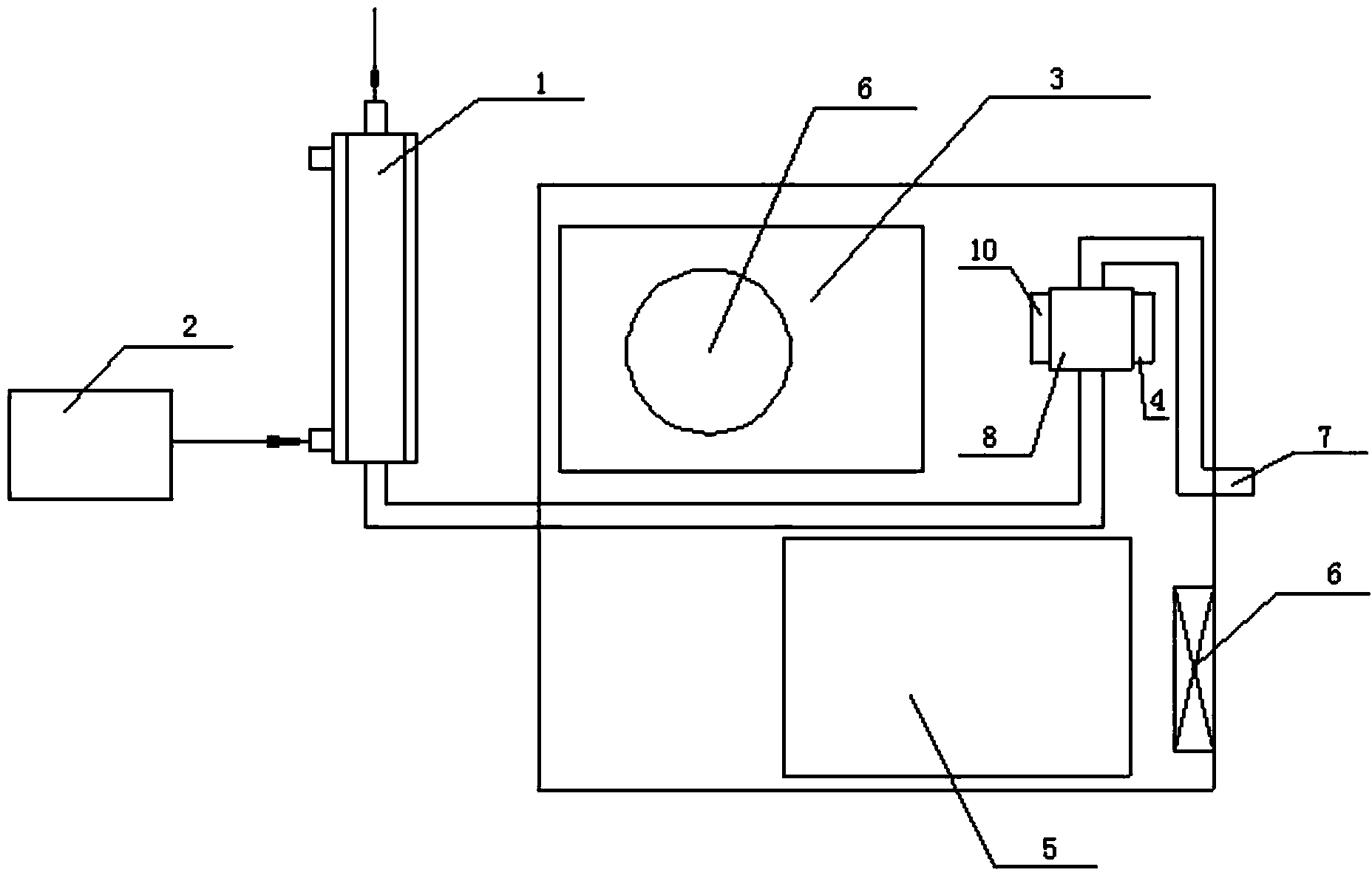

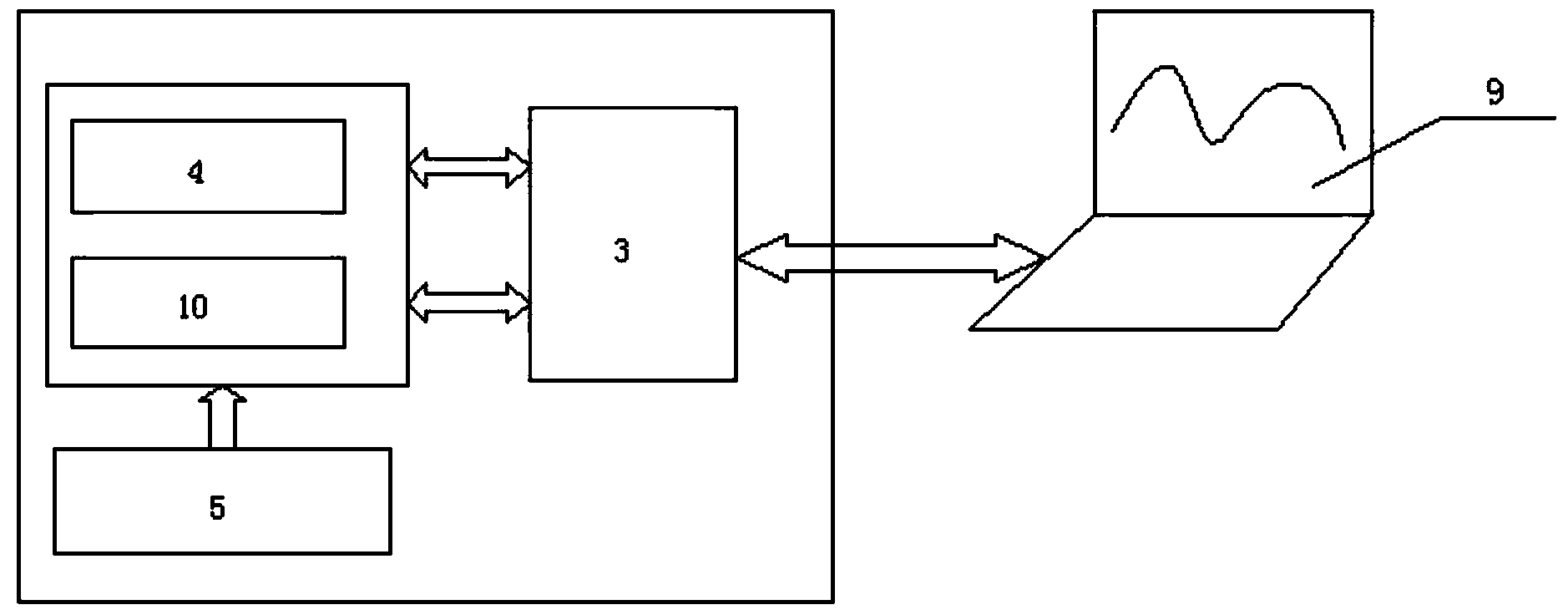

[0038] Embodiment: the junction box is made of aluminum alloy, the gas detection chamber 8 and its air inlet port and gas outlet port 7 are all made of plexiglass tubes, the Nafion tube water removal device is used to remove the gas moisture, and the regulated switching power supply is a commercially available 220v switching power supply And a cooling fan 6 is installed on its side to promote heat dissipation, and the gas sensor is an infrared carbon dioxide sensor 10 and an oxygen sensor 4 . The data acquisition system is centered on the Arduino single-chip microcomputer 3, and the optical sensor is connected by a wire, and the optical sensor sends data to the Arduino single-chip microcomputer 3. After the sensor data is processed by the Arduino single-chip microcomputer 3, it is sent to the PC terminal 9 through the data line, and the data drawing and analysis software of the PC terminal 9 Real-time display of data transmitted from Arduino MCU 3.

[0039] like figure 1 , 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com