Preparing method of orientation layer, orientation layer compound and display panel

An alignment layer and composition technology, applied in the field of liquid crystal display, can solve the problems of poor anchoring effect of liquid crystal molecules and general alignment effect, etc., and achieve good induction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

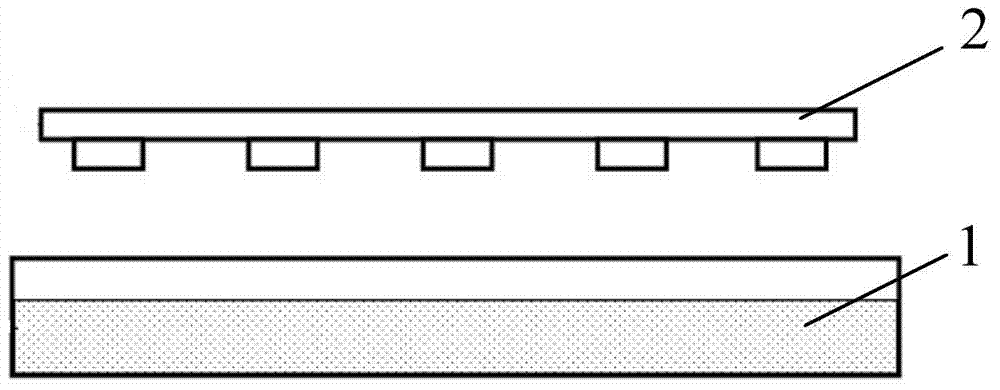

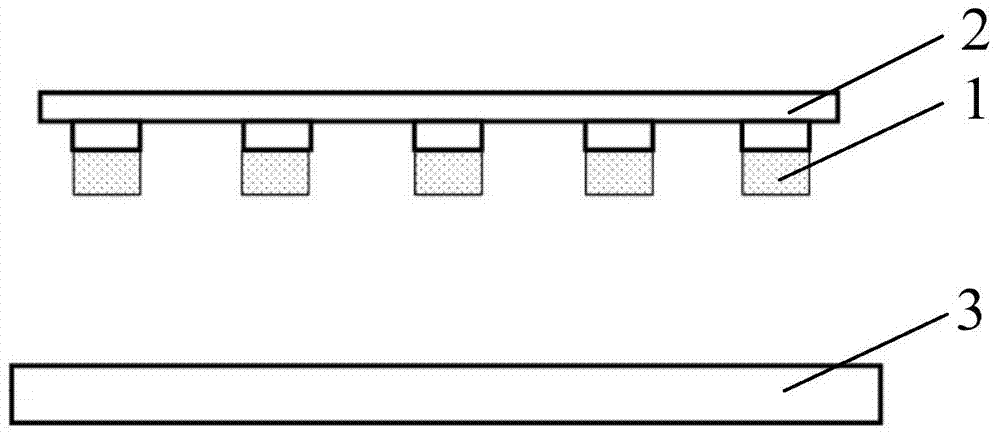

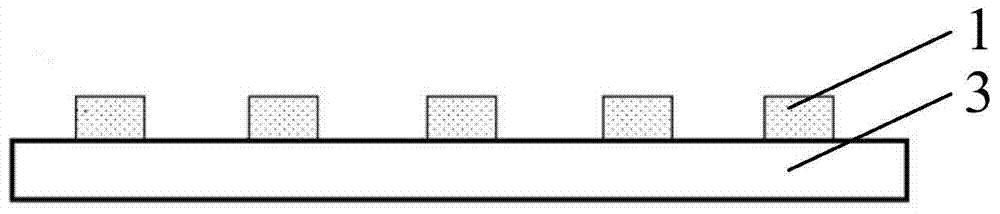

Method used

Image

Examples

Embodiment 1

[0100] A vertical alignment agent with a mass fraction of 5%, a discotic liquid crystal with a mass fraction of 20%, dibenzoyl peroxide with a mass fraction of 0.06%, and dichloromethane with a mass fraction of 74.94% are mixed to form a mixed solution. The mixed solution was degassed for 3 hours, and then transferred to the surface of the substrate with a transfer plate to form a pre-alignment layer; after the vertical alignment agent in the mixed solution was modified on the surface of the substrate, it was left to stand in the dark, and then heated in the dark to remove the mixed solution. organic solvents in solution. Then irradiate with ultraviolet light with a wavelength of 365nm, the irradiation time is 30min, and the irradiation intensity is 10mW / cm 2 , so that the pre-alignment layer and the discotic liquid crystal are polymerized under the initiation of the photoinitiator, thereby forming the discotic liquid crystal wall.

[0101] Among them, the chemical formula of...

Embodiment 2

[0103] A vertical alignment agent with a mass fraction of 10%, a discotic liquid crystal with a mass fraction of 20%, lauryl peroxide with a mass fraction of 0.07%, and dichloromethane with a mass fraction of 69.93% are mixed to form a mixed solution. The mixed solution was degassed for 5 hours, and then transferred to the surface of the substrate with a transfer plate to form a pre-alignment layer; after the vertical alignment agent in the mixed solution was modified to the surface of the substrate, it was heated in the dark to remove the mixed solution in organic solvents. Then irradiate with ultraviolet light with a wavelength of 365nm, the irradiation time is 30min, and the irradiation intensity is 30mW / cm 2, so that the pre-alignment layer and the discotic liquid crystal are polymerized under the initiation of the photoinitiator, thereby forming the discotic liquid crystal wall.

[0104] Among them, the chemical formula of the vertical alignment agent is n=4; the chemi...

Embodiment 3

[0106] A vertical alignment agent with a mass fraction of 15%, a discotic liquid crystal with a mass fraction of 25%, azobisisobutyronitrile with a mass fraction of 0.08%, and chloroform with a mass fraction of 59.92% were mixed to form a mixed solution. The mixed solution was degassed for 7 hours, and then transferred to the surface of the substrate with a transfer plate to form a pre-alignment layer; after the vertical alignment agent in the mixed solution was modified to the surface of the substrate, it was heated in the dark to remove the pre-alignment layer. organic solvents in solution. Then irradiate with ultraviolet light with a wavelength of 365nm, the irradiation time is 40min, and the irradiation intensity is 30mW / cm 2 , so that the pre-alignment layer and the discotic liquid crystal are polymerized under the initiation of the photoinitiator, thereby forming the discotic liquid crystal wall.

[0107] Among them, the chemical formula of the vertical alignment agent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com