Multi-degree-of-freedom teaching robot based on 51 single chip microcomputer

A technology of robots and single-chip microcomputers, applied in the field of multi-degree-of-freedom industrial robots, can solve problems such as equipment problems, and achieve the effect of reducing precision requirements and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

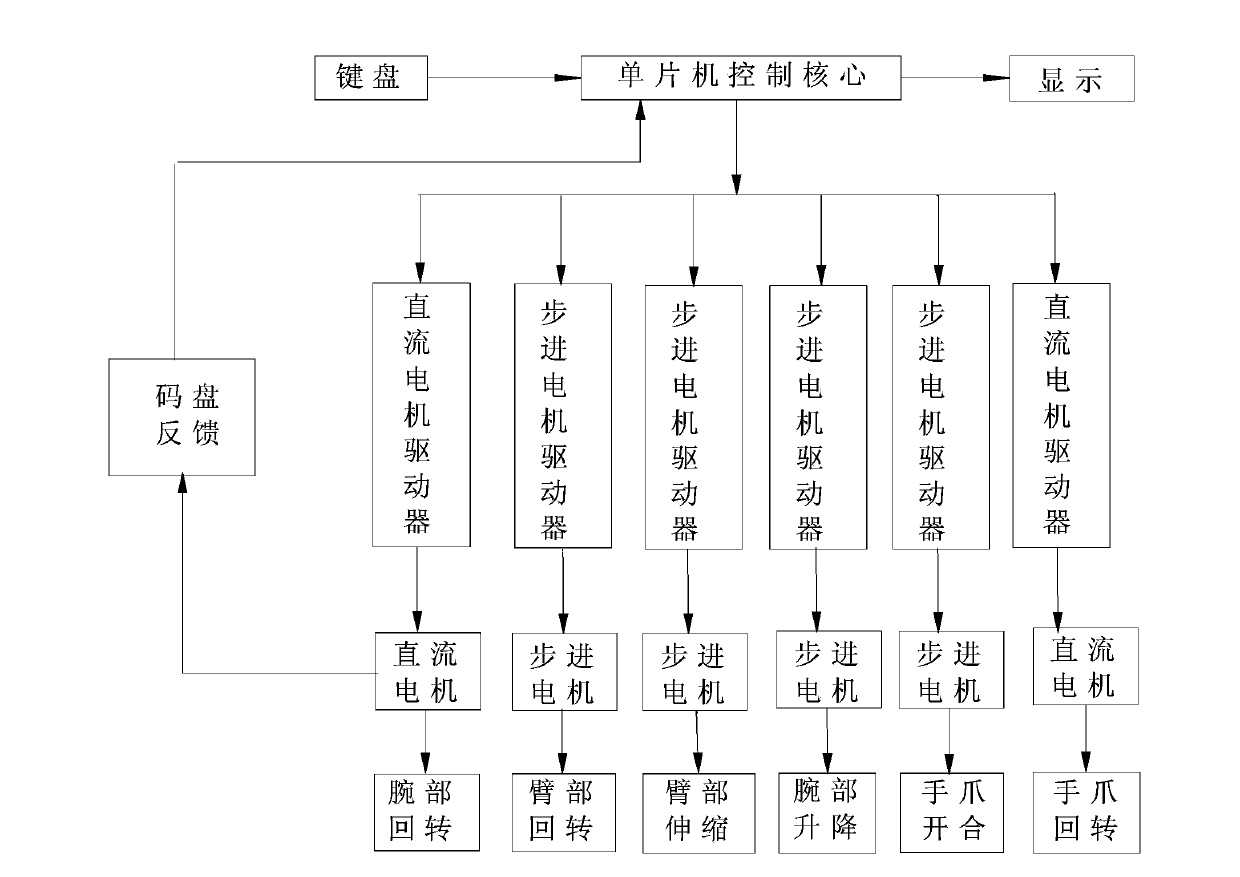

[0018] combine figure 1 , Driven by stepper motor and servo motor, controlled by 89C51 single-chip microcomputer, arm expansion, rotation, wrist lifting, and claw opening and closing are controlled by stepper motor open-loop; wrist rotation and claw rotation are controlled by DC motor closed-loop. Among them, the stepper motor is driven by a single-voltage constant-current source, and the control pulse signal is directly sent out by the single-chip microcomputer. The closed-loop control of the wrist is realized by adding a photoelectric code disc to a DC torque motor, and the display part adopts an LCD liquid crystal display module. Structural design of the hand gripper. In this system, the grasping weight is 5N, and the finger opening and closing is 5.10. We decided to choose the chute lever fulcrum swivel hand. This structure can change the size of the grip force and the opening and closing angle between the fingers through the angle or the length of the bars between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com