Application method of taking nano transition metal sulfide as positive electrode material of rechargeable magnesium battery

A transition metal, application method technology, applied in the direction of battery electrodes, active material electrodes, positive electrodes, etc., to achieve good electrochemical performance, no capacity decay effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

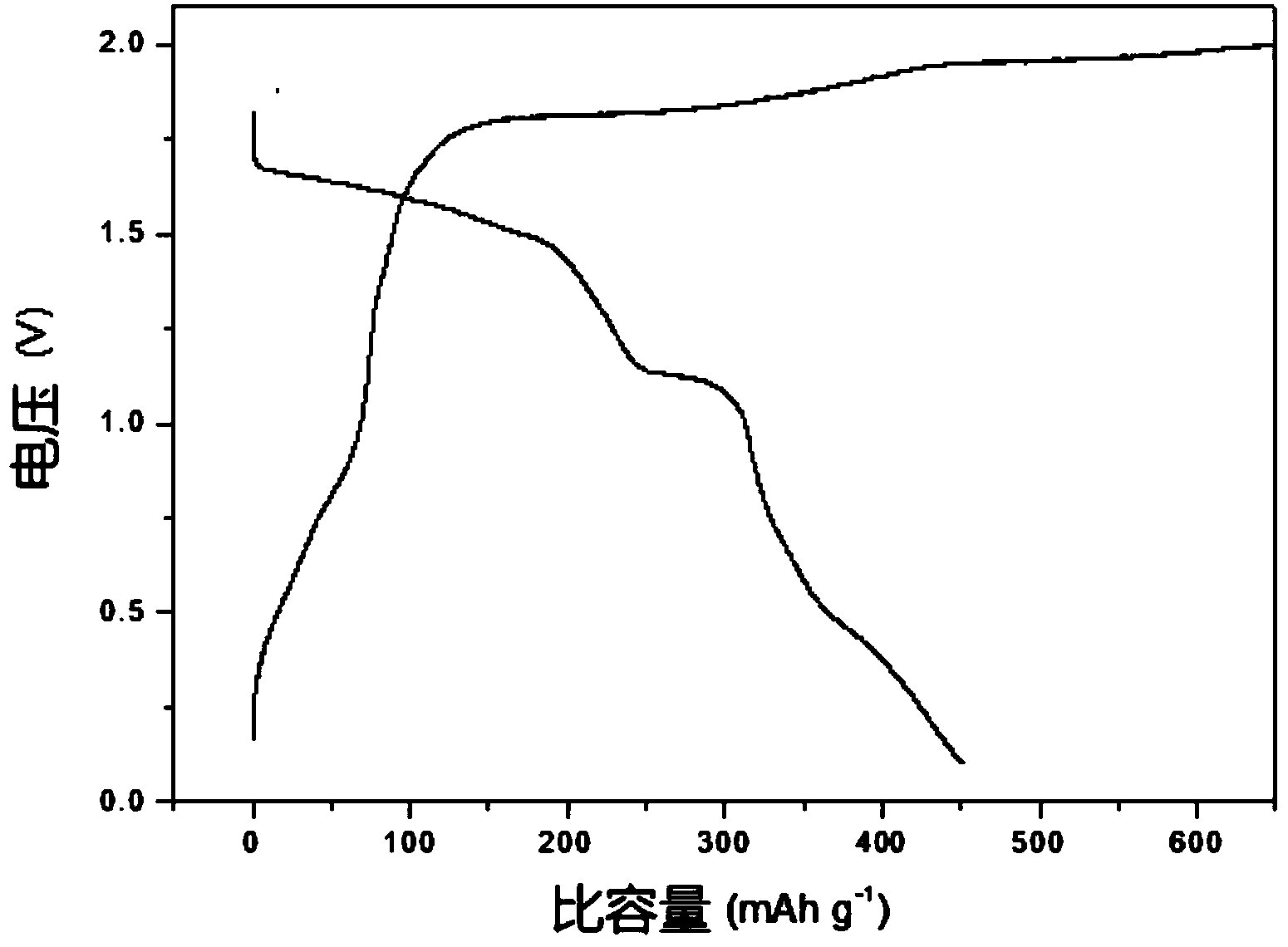

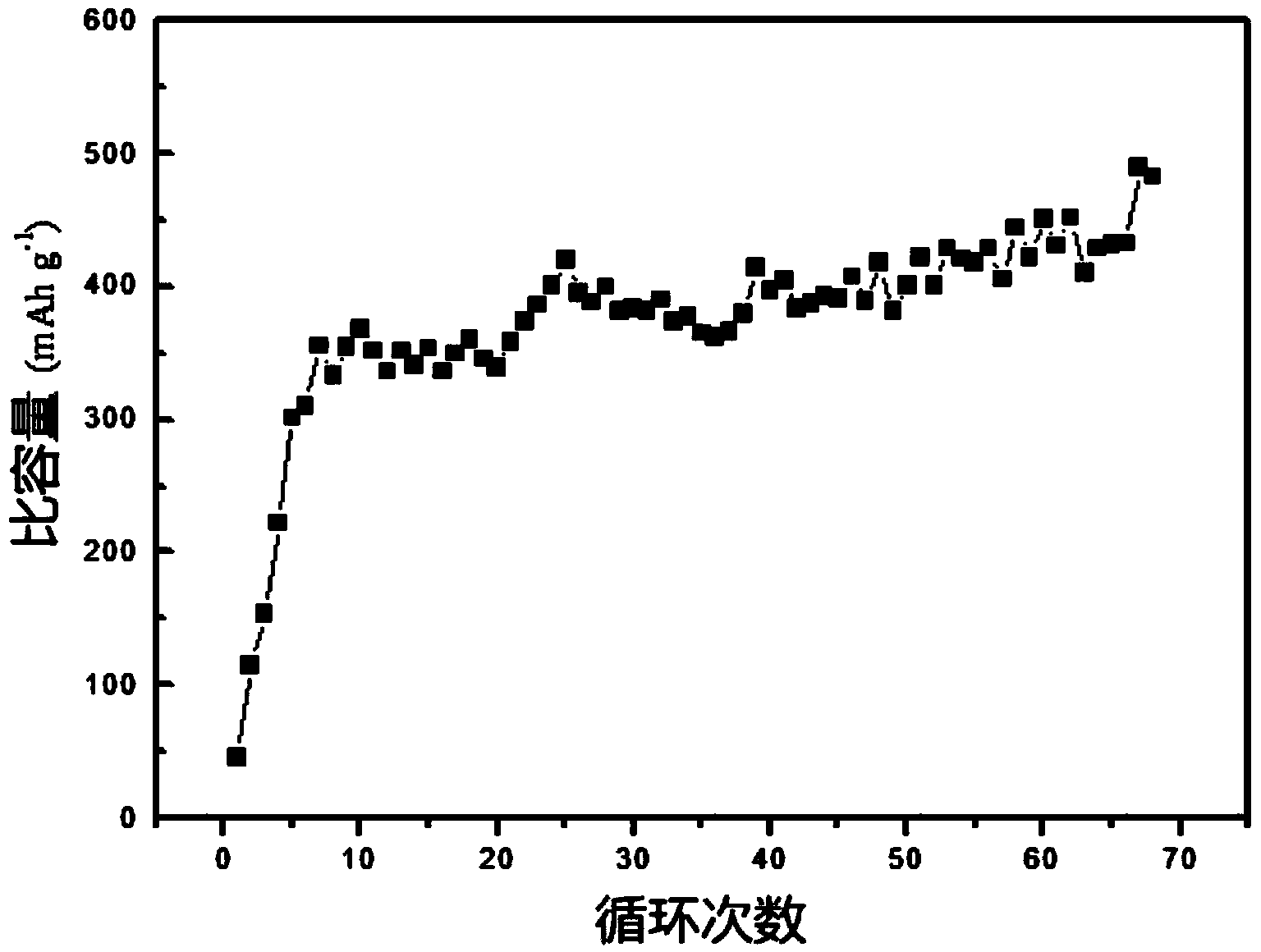

[0032] Embodiment 1: Nano Fe 3 S 4 Application in Rechargeable Magnesium Batteries

[0033] 1. Using Fe(SO 4 ) 2 ·6H 2 O and L-cysteine (C 3 h 7 NO 2 S) as the raw material, weighed according to the atomic molar ratio of Fe:S=1:4, and dissolved in 40ml deionized water respectively, after fully dissolving, mixed the two solutions and stirred for 30min to obtain Fe ion concentration of 0.05M light yellow transparent solution 80ml. The above 80ml solution was added into a high-pressure reactor with a polytetrafluoroethylene liner having an effective volume of 100ml, and the reactor was sealed. Transfer the sealed reactor to an oven, slowly raise the temperature to 160°C, keep it warm for 12 hours, and then cool with the furnace. Open the cooled reaction kettle, take out the lining, pour out the supernatant, wash the obtained gray-black solid several times with deionized water and absolute alcohol, and dry it in vacuum at 80°C to obtain nano-Fe 3 S 4 .

[0034] 2. Nano...

Embodiment 2

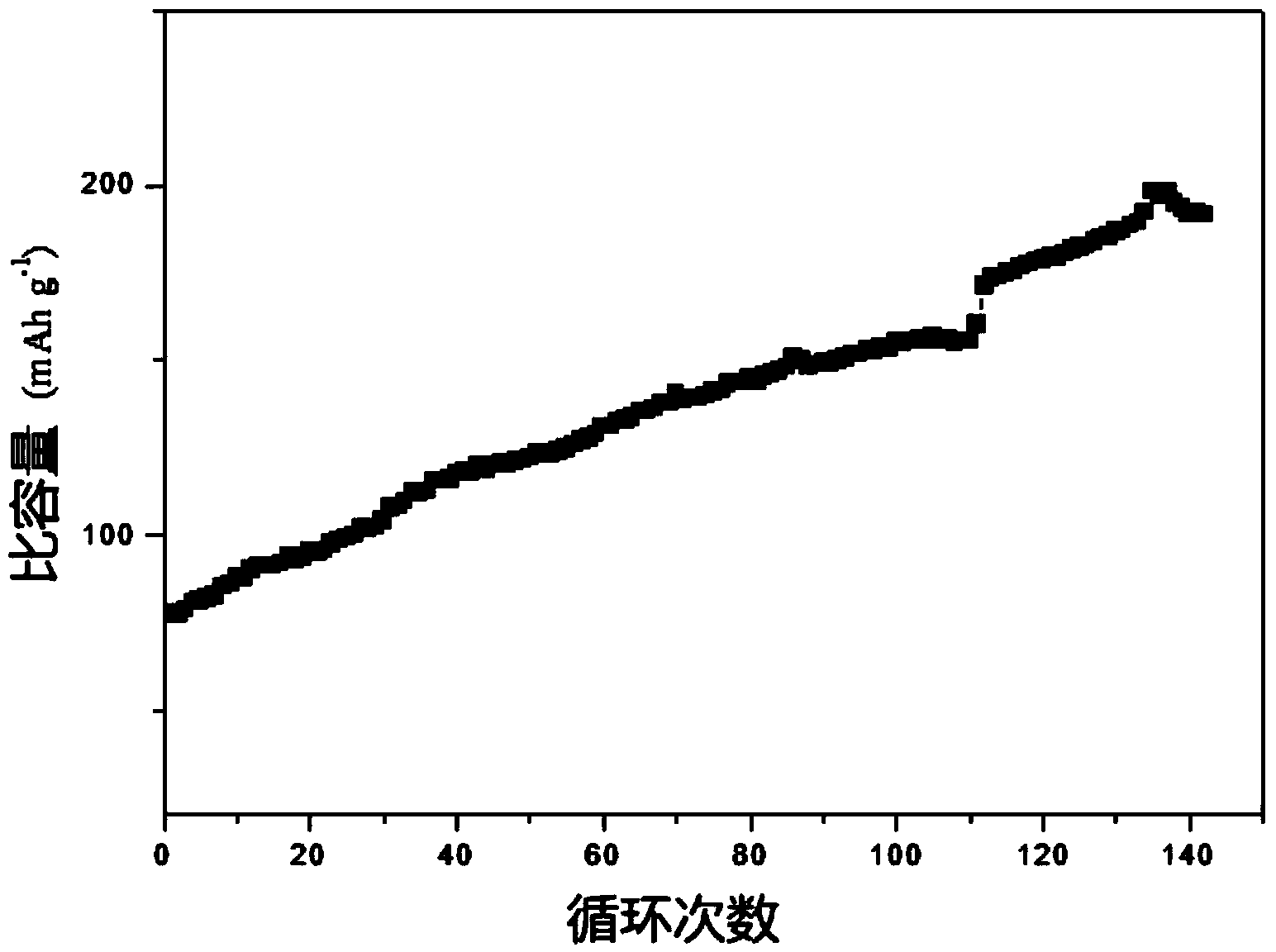

[0038] Embodiment 2: Nano NiFe 2 S 4 Application in Rechargeable Magnesium Batteries

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com