A method of making multi-layer microwave circuits using ceramic substrates

A technology of ceramic substrates and microwave circuits, which is applied in the manufacture of multilayer circuits, circuits, electrical components, etc., can solve the problems of easy fracture of metal layers, large differences in thermal expansion coefficients, and difficult metallization of through holes, etc. Controllable, high implementation precision, good cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

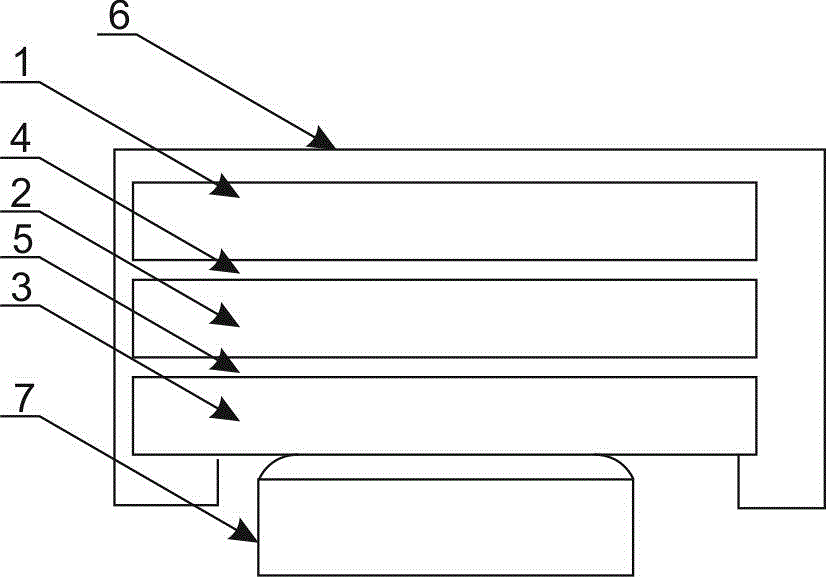

[0026] The ceramic substrate 2 is selected, and a through hole is made on it, and the through hole can be obtained by mechanical or laser drilling. The upper filling board 1 , the ceramic substrate 2 and the lower filling board 3 are stacked sequentially from top to bottom, and the upper filling board 1 and the lower filling board 3 can be made of ceramics. The lower filling plate 3 is provided with a filling port vertically corresponding to the through hole. The sizes of the through hole and the filling port are both in the micron order, but the size of the through hole is larger than that of the filling port, and the radius of the filling port is less than half of the radius of the through hole. one.

[0027] There is a gap 1 between the upper filling plate 1 and the ceramic substrate 2, and there is a gap 2 5 between the ceramic substrate 2 and the lower filling plate 3. The height of the gap 1 4 and the gap 2 5 is 1-20 mm. The first gap 4 and the second gap 5 are used to ...

Embodiment 2

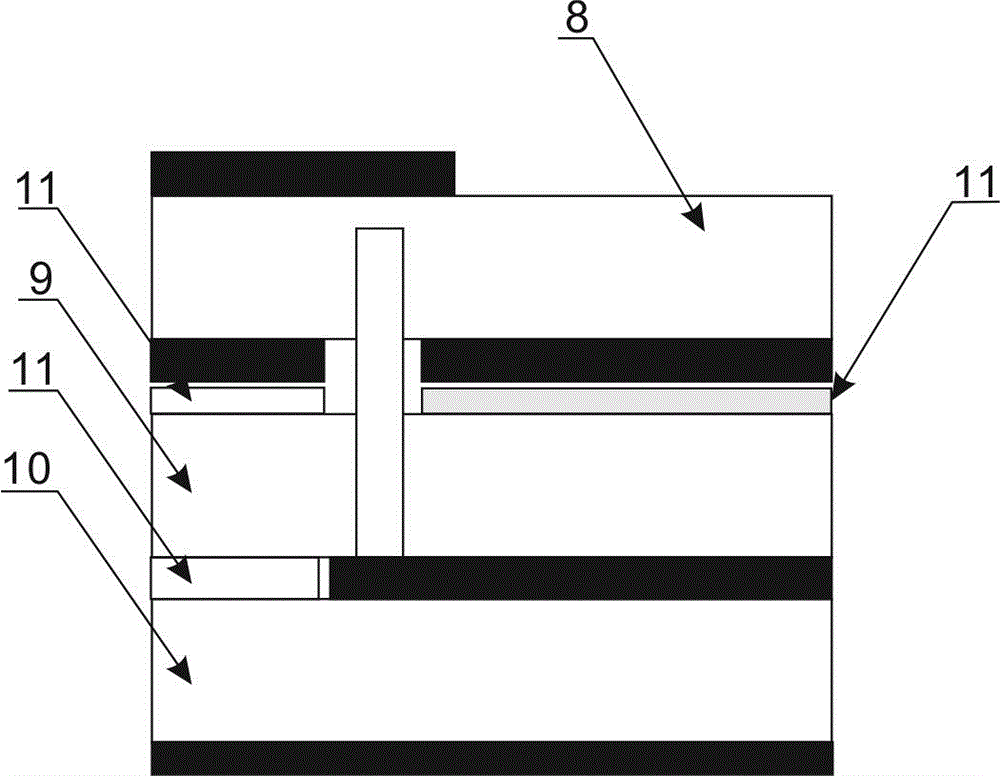

[0034] Fabrication of Microwave Circuits on Three-Layer Ceramic Substrates

[0035] Corresponding through holes are opened on the first ceramic substrate 8 and the second ceramic substrate 9, and the upper filling plate 1 and the lower filling plate 3 are used to fill the through holes of the two ceramic substrates 2 with metal. Make circuit diagrams on the first layer of ceramic substrate 8 and the third layer of ceramic substrate 10, then coat photoresist 11, and remove the photoresist 11 at the through hole, then the three ceramic substrates are superimposed and heated to The metal is melted so that the three layers of ceramic substrates are connected through holes, so as to realize the electrical connection between the first layer and the third layer.

Embodiment 3

[0037] The above-mentioned embodiment 1 provides a method for manufacturing a multilayer microwave circuit, in which the liquid metal in the liquid metal tank 6 needs to be pressed into the through hole of the ceramic substrate 2 . In the present invention, the through hole and the filling port can be cylindrical, and the filling port can be trapezoidal. When the liquid metal rises into the through hole, the pressure difference between the inside of the ceramic substrate 2 and the external atmospheric pressure is greater than twice the ratio of the surface tension coefficient of the liquid metal to the radius of the filled hole. When the through hole is filled, the inside of the ceramic substrate 2 and the outside The pressure difference at atmospheric pressure is less than the ratio of the surface tension coefficient of the liquid metal to the radius of the filled pores.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com