Emulsifier composition, stable ready-to-use microemulsion comprising the same, and method of making the same

A technology of microemulsion and composition, applied in food ingredients as emulsifiers, food ingredients containing organic compounds, applications, etc., can solve problems such as long storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

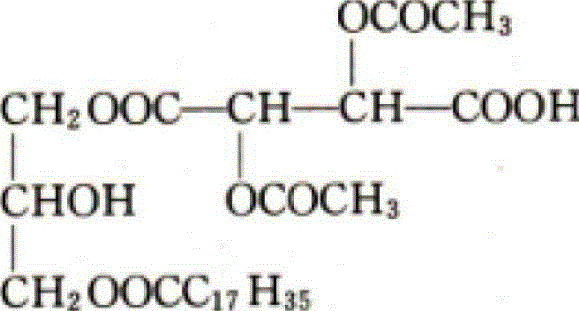

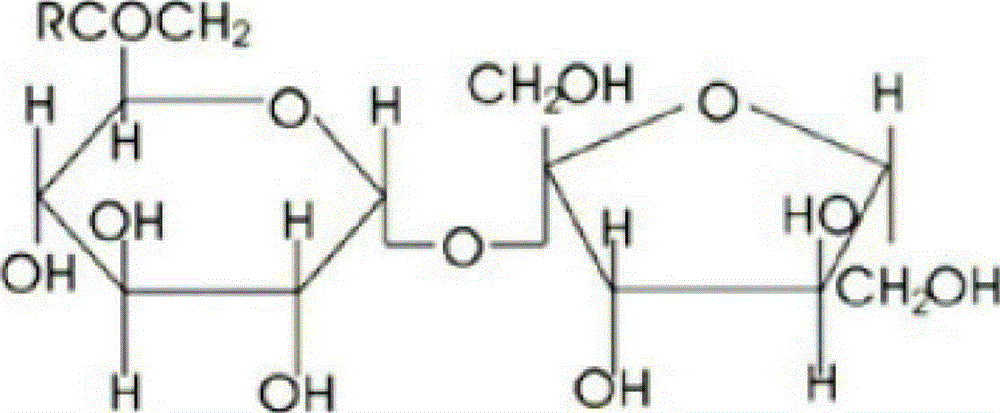

Method used

Image

Examples

Embodiment 1

[0085] Diacetyl tartrate mono(dig)glyceride (content: 1.25% by weight, based on the weight of the prepared milky stable emulsion, HLB value = 8.3, purchased from BASF (China) Co., Ltd.) and sucrose ester S1670 (content 0.50% by weight, based on the weight of the milk-like stable emulsion prepared, HLB value = 16, purchased from Mitsubishi Chemical Corporation) added to the water phase of 0.4% sodium caseinate solution (the water phase accounts for the entire water package 75% by weight of the oil system), adjust the pH to 7; monoglyceride (glyceryl monostearate) (content is 1.00% by weight, based on the weight of the milky stable emulsion prepared, HLB value = 3.8, (purchased from Meichen Group Additive Company) was added to the oil phase (pure fish oil, sourced from Zhejiang Shenzhou Marine Biology Co., Ltd., the oil phase accounted for 25% by weight of the entire oil-in-water system); Add water phase, pre-shear condition is 10000rpm for 5 minutes; then use APV homogenizer to...

Embodiment 2

[0091] Diacetyl tartrate mono(dig)glyceride (content: 1.84% by weight, based on the weight of the prepared milk-like stable emulsion, HLB value = 9.0, purchased from BASF (China) Co., Ltd.), sucrose ester S1570 (content 0.55% by weight, based on the weight of the milk-like stable emulsion prepared, HLB value=15, purchased from Mitsubishi Chemical Co., Ltd.) added to the water phase of 1% sodium caseinate solution (the water phase accounts for the entire 75% by weight of the oil system), adjust the pH to 7; monoglyceride (glyceryl monostearate) (content is 0.84% by weight, based on the weight of the milk-like stable emulsion prepared, HLB value = 3.6, (purchased from Meichen Group Additives Company) was added to the oil phase (algae oil, derived from Martek Bioscience Co., Ltd., the oil phase accounted for 25% by weight of the entire oil-in-water system); The water phase is added, and the pre-shear condition is 5000rpm for 5 minutes; after that, use an APV homogenizer to homo...

Embodiment 3

[0097] Diacetyl tartrate mono(dig)glyceride (content: 1.84% by weight, based on the weight of the prepared milk-like stable emulsion, HLB value = 9.2, purchased from BASF (China) Co., Ltd.), sucrose ester S1670 (content 0.50% by weight, based on the weight of the milk-like stable emulsion prepared, HLB value = 16, purchased from Mitsubishi Chemical Corporation) added to the water phase of 3% sodium caseinate solution (the water phase occupies the entire 75% by weight of the oil system), adjust the pH to 7; monoglyceride (glycerol monocitrate) (0.2% by weight, based on the weight of the milk-like stable emulsion prepared, HLB value = 4.0, purchased From Meichen Group Additive Company) into the oil phase (soybean oil, derived from Arowana soybean oil, the oil phase accounts for 25% by weight of the entire oil-in-water system); then slowly add the oil phase to the water phase during the pre-shearing process , the pre-shear condition is 8000rpm for 5 minutes; then use an APV homog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com