Preparation method of fish sauce

A fish sauce and finished product technology, which is applied in the field of food manufacturing, can solve the problems of single source of nutrition, shortened fermentation time, and poor flavor, and achieve the effect of good taste, better flavor, and shortened fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

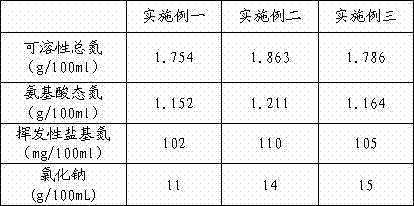

Examples

Embodiment 1

[0023] A kind of preparation method of fish sauce, carries out according to the following steps:

[0024] (1) 6 parts of hot-pressed bean cake, 2 parts of rice bran, 2 parts of millet and 5 parts of water are fully mixed, and steamed in a steamer for 1.5 hours under pressure at 0.2 MPa;

[0025] (2) The clinker obtained in step (1) is rapidly cooled to 45°C, inoculated with 0.04 parts of Aspergillus oryzae strains, mixed well, and the inoculated koji material is sent into the koji pond, and the product temperature is maintained at 30°C, and then put into the koji pond Ventilate intermittently after 5 hours, and ventilate continuously after 12 hours in the Qu pool; after 31 hours in the pool, the koji is made, and the koji is turned every half an hour during this period;

[0026] (3) Take 4 parts of anchovy, 3 parts of Balang fish, 5 parts of red fish, 2 parts of triangular fish plus 2 parts of salt, and marinate for 28 hours to obtain marinated miscellaneous fish;

[0027] (4...

Embodiment 2

[0033] A kind of preparation method of fish sauce, carries out according to the following steps:

[0034] (1) 5 parts of hot-pressed bean cake, 3 parts of rice bran, 2 parts of millet and 6 parts of water are fully mixed, and steamed in a steamer for 1 hour under pressure at 0.3 MPa;

[0035] (2) The clinker obtained in step (1) is rapidly cooled to 43°C, inoculated with 0.05 parts of Aspergillus oryzae strains, mixed well, and the inoculated koji material is sent into the koji pond, and the product temperature is maintained at 32°C, and put into the koji pond for 5 hours Afterwards, ventilate intermittently, and ventilate continuously after entering the Qu pool for 12 hours; after entering the Qu pool for 32 hours, the koji is made, and the koji is turned every half an hour during this period;

[0036] (3) Take 5 parts of anchovy, 4 parts of Balang fish, 5 parts of red fish, 2 parts of triangular fish plus 3 parts of salt, and marinate for 24 hours to obtain marinated miscell...

Embodiment 3

[0043] A kind of preparation method of fish sauce, carries out according to the following steps:

[0044] (1) 7 parts of hot-pressed bean cake, 3 parts of rice bran, 3 parts of millet and 5 parts of water are fully mixed, and steamed in a steamer for 1.2 hours under pressure at 0.2 MPa;

[0045] (2) The clinker obtained in step (1) is rapidly cooled to 42°C, inoculated with 0.05 parts of Aspergillus oryzae strains, mixed well, and the inoculated koji material is sent into the koji pond, and the product temperature is maintained at 31°C, and put into the koji pond for 5 hours Afterwards, ventilate intermittently, and then ventilate continuously after 12 hours into the koji pool; after 30 hours into the koji pool, the koji is made, and the koji is turned every half an hour during this period;

[0046] (3) Take 3 parts of anchovy, 5 parts of Balang fish, 4 parts of red fish, 3 parts of triangular fish and 2 parts of salt, and marinate for 30 hours to obtain marinated miscellaneou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com