Preparation method of tannin-loaded collagen/cellulose composite biological adsorption material

A technology of biological adsorption and collagen fibers, which is applied in chemical instruments and methods, and other chemical processes, can solve the problems of limited adsorption capacity and failure to improve the ability of collagen to withstand microbial action, so as to avoid denaturation and reusable performance. , The effect of improving the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Collect waste ash and alkali skins from the tanning industry, deash, wash, and grind. Take 30g of minced skin, add it to 900mL of acetic acid solution (2.0% by volume), add 0.3g of pepsin, centrifuge at 3000r / min, take the supernatant and freeze-dry to obtain spongy collagen fibers.

[0031] (2) Dissolve 1.5g of cellulose powder (cellulose content=95wt%, degree of polymerization=300) in 40g of EmimAc ionic liquid, and control the temperature at 40°C to completely dissolve the cellulose to obtain an ionic liquid containing cellulose, and cool down.

[0032] (3) Add 0.15 g of collagen fibers obtained in step (1) to the ionic liquid containing cellulose obtained in step (2), and stir to completely dissolve the collagen fibers to obtain an ionic liquid containing cellulose / collagen.

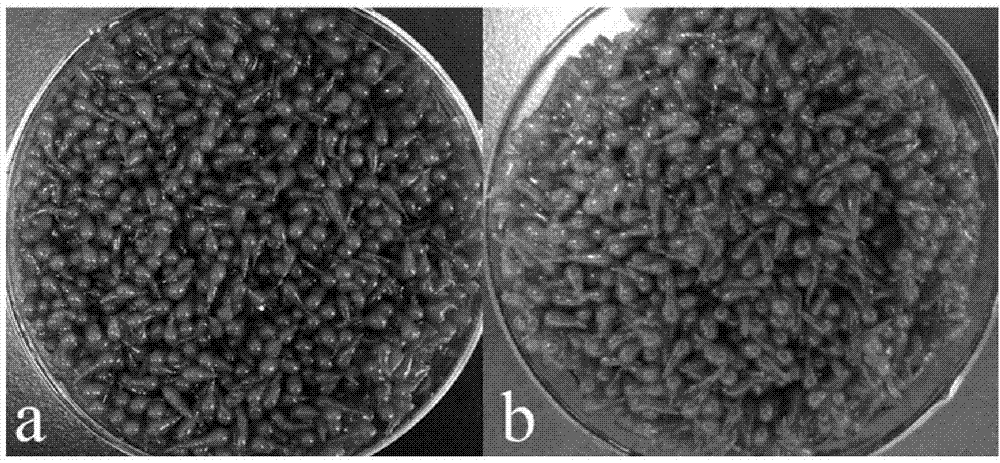

[0033] (4) The ionic liquid containing cellulose / collagen obtained in step (3) was added dropwise into the ethanol-water solution with a concentration of 6% by volume with a syringe, and th...

Embodiment 2

[0037] (1) Collect waste ash and alkali skins from the tanning industry, deash, wash, and grind. Take 20g of minced skin, add it to 800mL of acetic acid solution (1.0% by volume), add 0.25g of pepsin, centrifuge at 4000r / min, take the supernatant and freeze-dry to obtain spongy collagen fibers.

[0038] (2) Dissolve 2.5g of cellulose powder (cellulose content=95%, degree of polymerization=300) in 40g of [Bmim][BF 4 ] in the ionic liquid, heated to 75°C to dissolve the cellulose completely, and obtained the ionic liquid containing cellulose, and cooled.

[0039] (3) Add 0.40 g of the collagen fibers obtained in step (1) to the cellulose-containing ionic liquid obtained in step (2), and stir to completely dissolve the collagen fibers to obtain a cellulose / collagen-containing ionic liquid.

[0040] (4) The ionic liquid containing cellulose / collagen obtained in step (3) was added dropwise into the ethanol-water solution with a concentration of 8% by volume with a syringe, and the...

Embodiment 3

[0043] (1) Collect waste ash and alkali skins from the tanning industry, deash, wash, and grind. Take 10 g of minced skin, add it to 600 mL of acetic acid solution (1.8% by volume), add 0.30 g of pepsin, centrifuge at 2500 r / min and take the supernatant for freeze-drying to obtain spongy collagen fibers.

[0044] (2) Dissolve 2.0g of cellulose powder (cellulose content = 95wt%, degree of polymerization = 300) in 50g of AmimCl ionic liquid, heat to 100°C to completely dissolve the cellulose, obtain ionic liquid containing cellulose, and cool .

[0045] (3) Add 0.12 g of the collagen fibers obtained in step (1) to the ionic liquid containing cellulose obtained in step (2), and stir to completely dissolve the collagen fibers to obtain an ionic liquid containing cellulose / collagen.

[0046] (4) The ionic liquid containing cellulose / collagen obtained in step (3) is scraped with a film scraper, placed in an ethanol-water solution with a concentration of 12% by volume, and the cellu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com