Method for preparing graphene based nano composite material through in-situ reduction of graphite oxide

A nano-composite material, graphene-based technology, applied in the direction of graphene, nano-carbon, material electrochemical variables, etc., can solve the problems of cumbersome process, complicated steps, easy residual impurities, etc., to achieve universality and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0032] with SnO 2 -rGO and ZnO-rGO are taken as examples to describe the method process in detail.

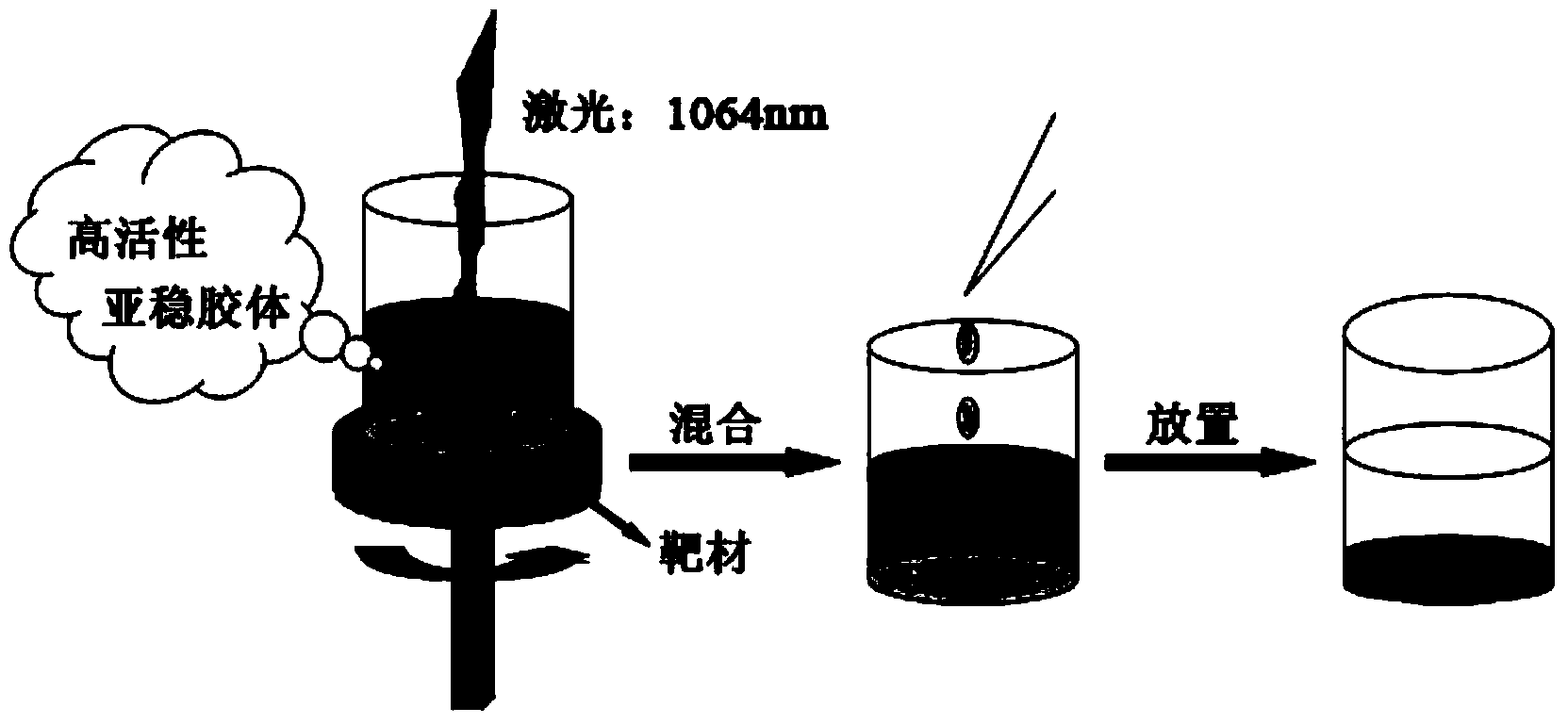

[0033] The specific experimental procedure is as figure 1 Shown:

[0034] The metastable nanomaterial colloid with high activity and high reactivity is obtained after pulsed laser ablation by rotating metal target, which is mixed with graphite oxide prepared by the classic Hummers method and then placed in a dark place.

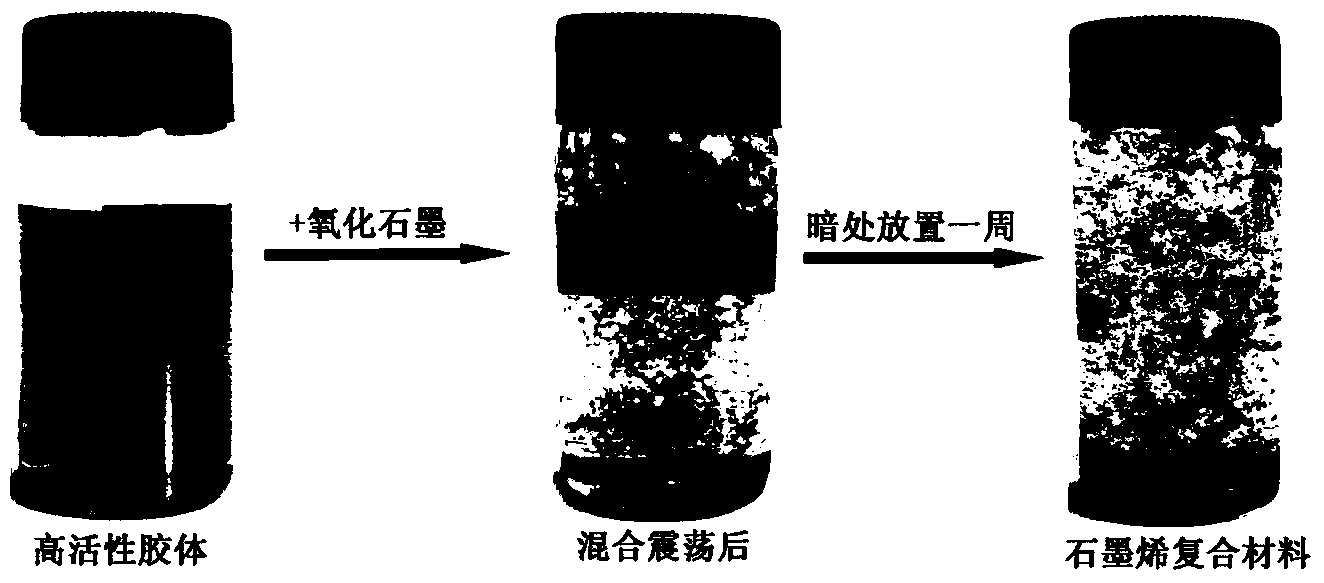

[0035] Such as figure 2 As shown, after one week, the product changed from yellow flocs to black flocs when initially mixed. Firstly, the reduction of graphite oxide and the generation of graphene are proved by the color.

[0036] Such as Figure 3a , 3b 、 As shown in 3c, in order to characterize the morphology of the product, TEM of the product was done, ( Figure 3a ) is graphene oxide prepared by the classic Hummers method. It can be seen from the figure that the obtained graphite oxide is uniform and free of impurities. The SEAD diagram in the uppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com