Resin anchoring agent realizing rapid loading under water and preparation method thereof

A resin anchoring agent and rapid technology, applied in the field of resin anchoring agent and its preparation, can solve the problem that the anchoring agent cannot be cured quickly and provide sufficient anchoring force quickly, and achieve the effect of reliable anchoring material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

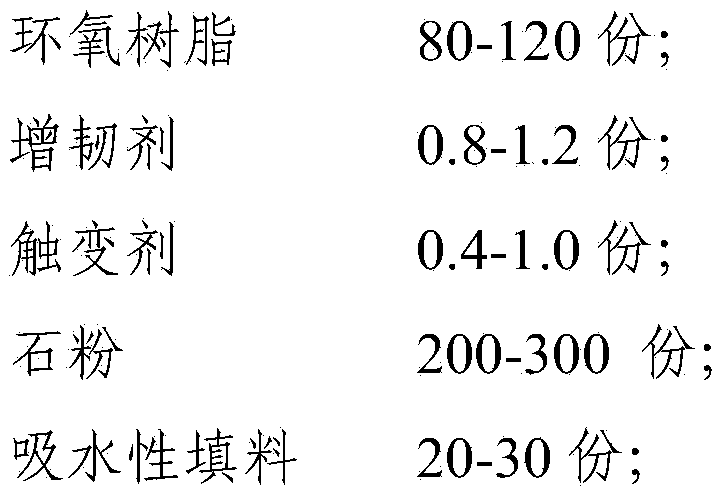

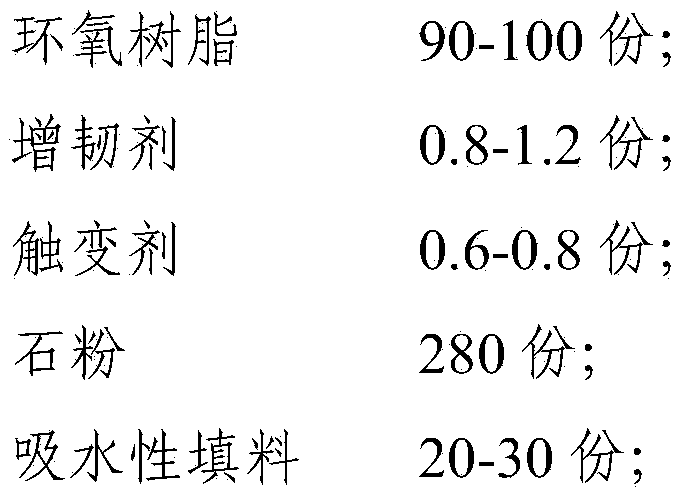

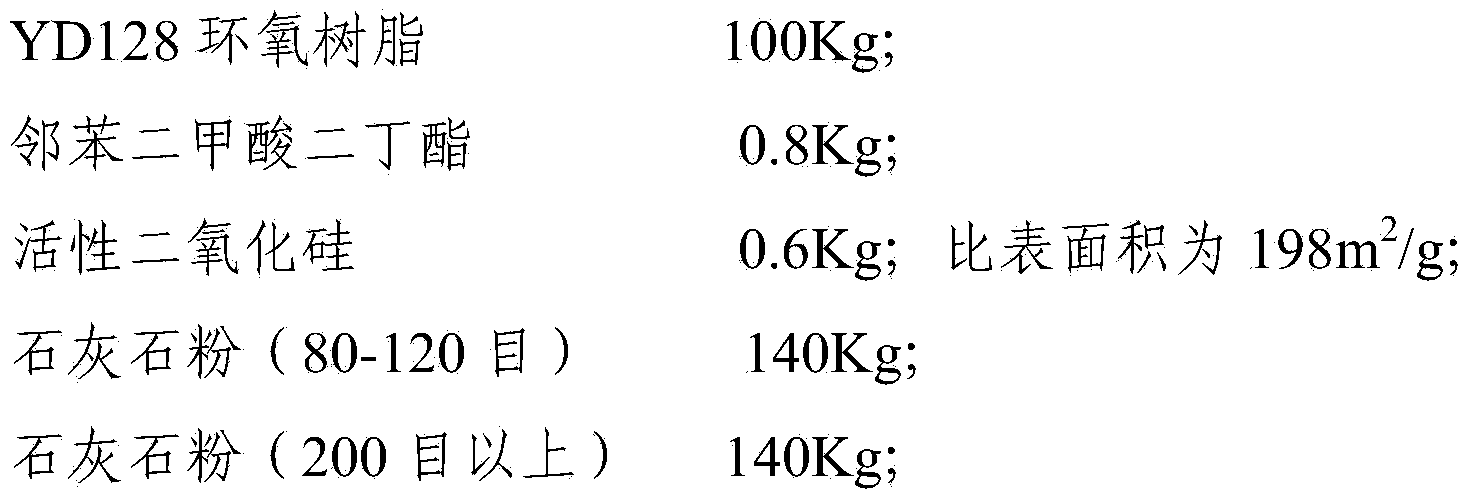

[0040] A resin anchoring agent capable of rapidly bearing underwater is prepared from the following components:

[0041]

[0042]

[0043] The total of the above components: 401.4kg;

[0044]

[0045] The above-mentioned components add up to 102kg.

[0046] The preparation method of the fast-carrying resin anchoring agent under water is:

[0047] 1. Preparation of epoxy resin mastic:

[0048] Add dibutyl phthalate and active silicon dioxide to the epoxy resin in sequence and stir evenly; add calcium oxide to the limestone powder and mix evenly, and add it to the epoxy resin liquid prepared above, stir and mix evenly into epoxy glue.

[0049] 2. Preparation of organic amine curing agent:

[0050] Add DMP-30 to ketimine and stir evenly; pour nano-calcium oxide, talcum powder and montmorillonite into the mixture of ketimine and DMP-30 and stir evenly to make an organic amine curing agent.

[0051] 3. Preparation of resin anchoring agent:

[0052] Seal one end of th...

Embodiment 2

[0055] A kind of resin anchoring agent of rapid loading under water, its following components are made:

[0056]

[0057]

[0058] The total of the above components is 401.7Kg;

[0059]

[0060] The above-mentioned components add up to 101Kg.

[0061] The preparation method of the fast-carrying resin anchoring agent under water is:

[0062] 1. Preparation of epoxy resin mastic:

[0063] Add dioctyl phthalate and active silicon dioxide to the epoxy resin in sequence and stir evenly; add calcium oxide to the dolomite powder and mix evenly, and add it to the epoxy resin liquid prepared above, stir and mix evenly into epoxy glue.

[0064] 2. Preparation of organic amine curing agent:

[0065]Add isophorone diaminomethyl phenol into isophorone diamine and stir evenly; pour nano talcum powder and calcium oxide into isophorone diamine and isophorone diamino methyl Mixed solution of phenol and stir evenly to make organic amine curing agent.

[0066] 3. Preparation of re...

Embodiment 3

[0070] A kind of resin anchoring agent of rapid loading under water, its following components are made:

[0071]

[0072] The total of the above components is 407Kg;

[0073]

[0074] The above components add up to 102.5Kg.

[0075] The preparation method of the fast-carrying resin anchoring agent under water is:

[0076] 1. Preparation of epoxy resin mastic:

[0077] Add dioctyl phthalate and active silicon dioxide to the epoxy resin in turn and stir evenly; add calcium oxide to the limestone powder and mix evenly, and add to the epoxy resin liquid prepared above, stir and mix Evenly into epoxy resin cement.

[0078] 2. Preparation of organic amine curing agent:

[0079] Add methylcyclopentadiaminomethylphenol into phenalkamine and stir evenly; pour nano-talc powder and calcium oxide into the mixture of phenalkamine and methylcyclopentadiaminomethylphenol and stir evenly , made of organic amine curing agent.

[0080] 3. Preparation of resin anchoring agent:

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com