Functionalized azo initiator for free radical polymerization as well as preparation and application methods thereof

An azo initiator and free radical technology, which is applied in the field of functionalized azo initiator for free radical polymerization and its preparation and application, can solve problems such as instability, and achieve an increase in the absorption coefficient and a stable molecular structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

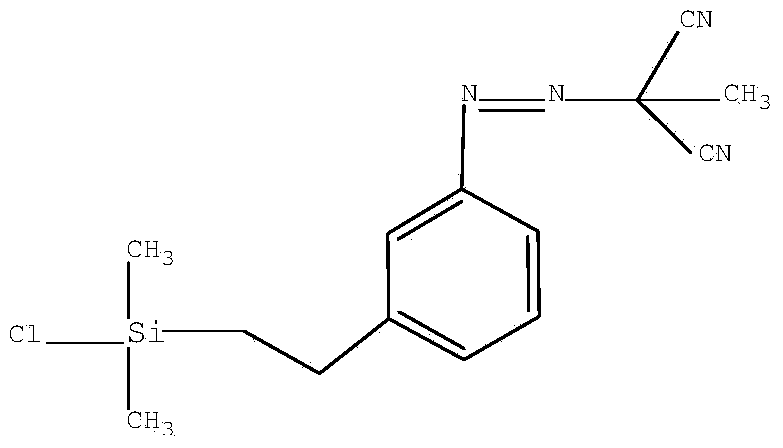

[0039] Initiator synthesis process:

[0040] (1) Synthesis of methylmalonamide

[0041] At room temperature, 172 mL (1 mol) of diethyl methylmalonate was poured into 200 mL of 27% ammonia water, and stirred at 45°C for 15 hours. When the solution became clear, it was cooled to 0°C to crystallize the product. The product was filtered and washed 2 times with methanol. After recrystallization in water, the product was dried under vacuum and the product weighed 33 g of colorless crystals (yield about 28%).

[0042] Product melting point: 208.9-209.2°C (222:209°C); infrared (IR, KBr) characteristic peak positions: 3353-3177, 2994, 2942, 1678cm -1 ; 1 H NMR (DMSO, ppm): 7.2, 7.4 (s, 4H, NH 2 ), 3.2(q, 1H, CH), 1.3(d, 3H, CH 3 ).

[0043] (2) Synthesis of methylmalononitrile

[0044] Take 8g (0.068mol) of methylmalonamide and 36g (0.296mol) of phosphorus pentoxide and mix them in a three-necked flask, and connect the three-necked flask to the distillation device. The system ...

Embodiment 2

[0056] Fabrication of Polymethacrylic Acid (PMAA) "Micropatterns"

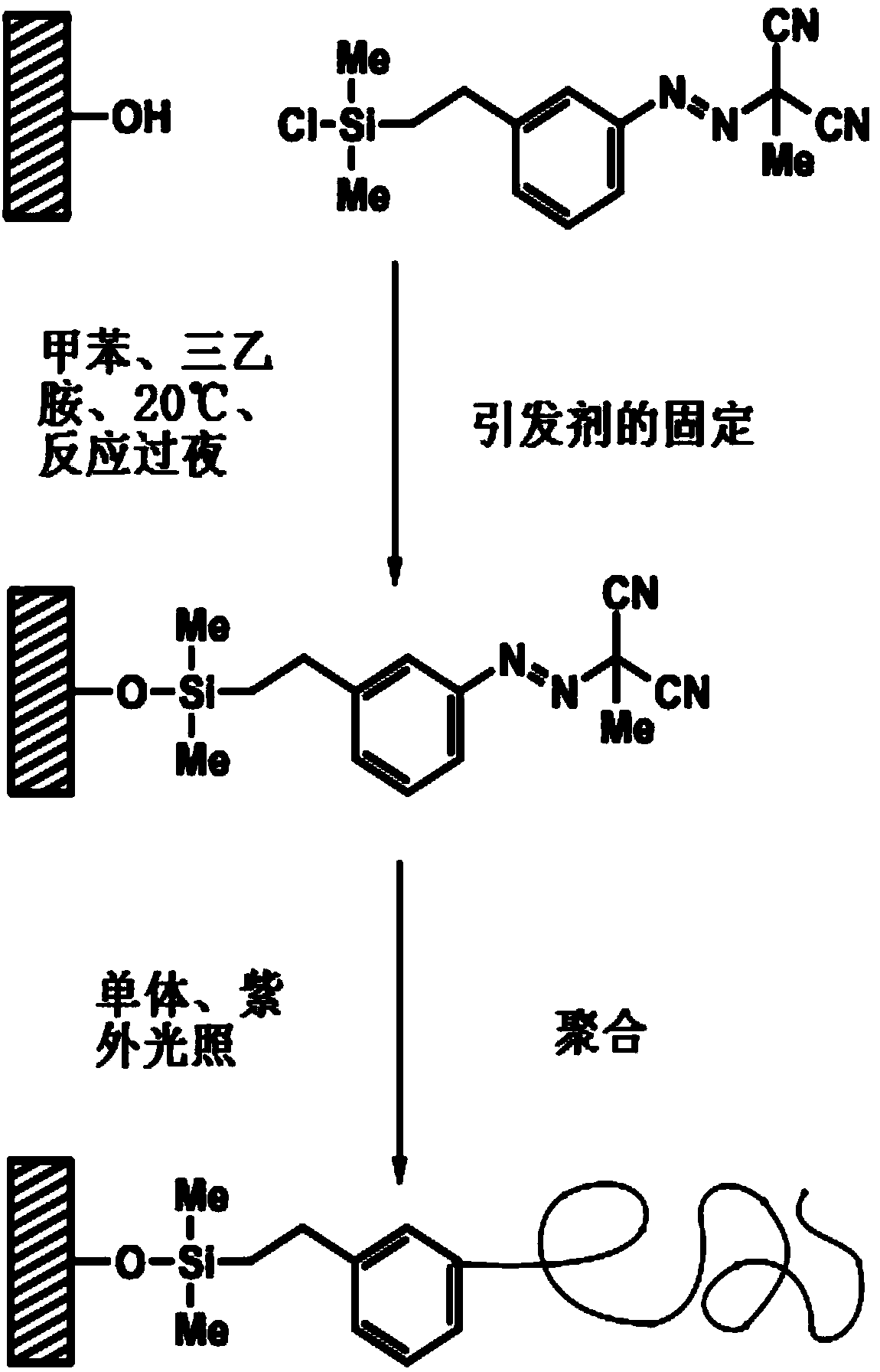

[0057] First, the silicon wafer is used as the substrate, and the initiator dimethylchlorosilyl-3-ethylbenzazomethylmalononitrile (CSAM) is fixed on the surface of the substrate. The fixation steps are as follows:

[0058] At room temperature, put the initiator and the silicon substrate into the Schlenk tube at the same time, use toluene as the solvent, and blow nitrogen to remove oxygen. The concentration of the initiator is 0.5mmol / L (the concentration of the initiator in toluene), add a few drops (0.5 ~ 2ml) of triethylamine as a catalyst, keep it overnight, take it out, and use toluene, methanol, acetone to dissolve the unfixed initiator and The by-products are extracted and dried under vacuum.

[0059] After the initiator is fixed, monomers can be added to initiate polymerization. In order to realize the production of "micropatterns", two ways are provided here, as follows:

[0060] The first one: cover...

Embodiment 3

[0065] Synthesis of polystyrene (PS)

[0066] Take 1.079g (3.5mmol) of the synthesized initiator dimethylchlorosilyl-3-ethylbenzazomethylmalononitrile (CSAM), and add it to a mixed solution of 300mL styrene monomer and toluene (benzene The volume ratio of ethylene to toluene is 1:1), after 5 cycles of freezing-vacuum-thawing to remove the air inside, the mixed solution after removing the air is subjected to free radical polymerization under the protection of nitrogen at 60°C, the polymerization reaction The time is 1.5 to 14 hours. After the polymerization is completed, the polymer is washed with methanol to remove residual monomers. The product was then dissolved in benzene and freeze-dried to obtain a solid product.

[0067] Tested by GPC, the molecular weight of the polymerized product is 1×10 4 ~1×10 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com