Steel surface cleaning agent and application thereof

A steel surface and cleaning agent technology, applied in the field of detergent, can solve the problems of difficult cleaning of oil stains, difficult cleaning, energy consumption, etc., and achieve the effect of short cleaning time and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

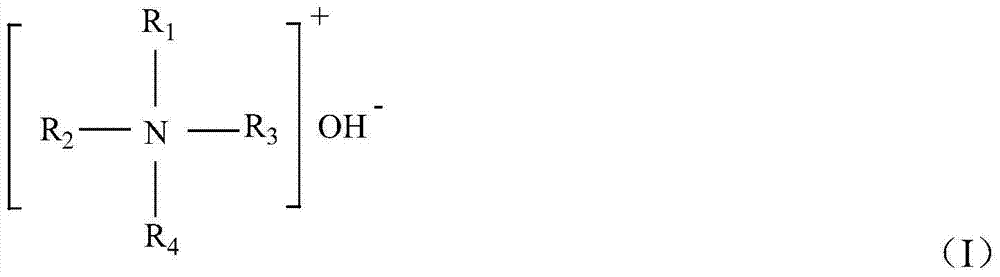

Method used

Image

Examples

Embodiment 1

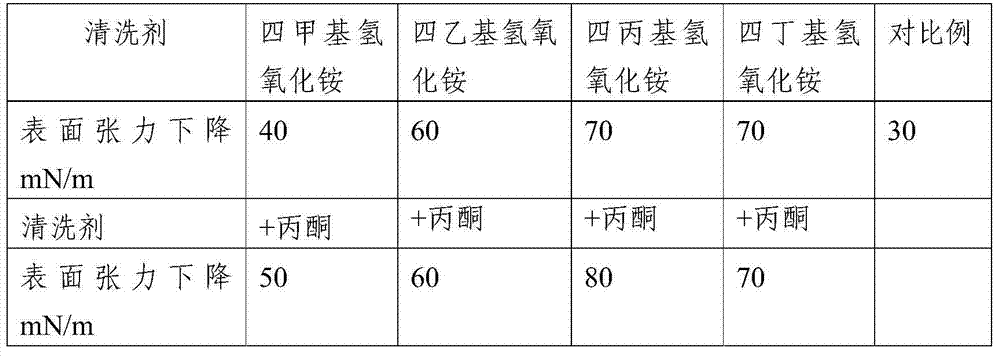

[0026] Embodiment 1: cleaning test

[0027] Cleaning agent is respectively the aqueous solution of 6wt% tetramethylammonium hydroxide, tetraethylammonium hydroxide, tetrapropylammonium hydroxide, tetrabutylammonium hydroxide, 6wt% tetraethylammonium hydroxide, tetrapropylammonium hydroxide, An aqueous solution of one of tetrabutylammonium hydroxide and 2 wt% acetone (indicated by + acetone in Table 1).

Embodiment 2

[0036] Embodiment 2 equipment cleaning

[0037] Newly invested chemical equipment, including tower equipment, etc. First, use a commercially available steel cleaning agent to circulate and wash for seven days. Unsmooth parts can be observed on the surface of the equipment after cleaning.

[0038] Then, inject 6wt% tetrapropylammonium hydroxide aqueous solution into the equipment at a flow rate of 5m / s, and the circulating cleaning agent will appear black. Clean it in a cycle (seven days), inject it with clean water, the water is clear and transparent, the surface of the equipment is smooth, and there is no oil stain at all.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com