Papermaking additive composition and preparation method thereof

A technology of papermaking auxiliary agent and composition, which is applied in the field of papermaking auxiliary agent composition and its preparation, which can solve the problems of mildew, low strength, complicated process, etc., and achieve the effect of eliminating bad foam and increasing paper hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) 30 kg of polyoxypropyl glyceryl ether, 20 kg of alkali-free glass fiber, 12 kg of polyhexamethylene guanidine hydrochloride with a relative molecular weight of 1500, 3 kg of 4,4'-diphenylmethane-diisocyanate and disodium hydrogen sulfate 2kg, placed in a nitrogen atmosphere, at 80°C, 600 rpm, stirred for 2 hours;

[0029] (2) Add 25kg of glyceryl stearate and 10kg of calcium carbonate whiskers to the product of step (1), and mix uniformly to obtain a papermaking auxiliary composition.

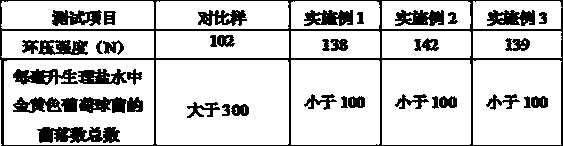

[0030] Table 1 shows the performance test results of the prepared papermaking auxiliary composition.

Embodiment 2

[0032] (1) 35kg of polyoxypropyl glyceryl ether, 30kg of alkali-free glass fiber, 15kg of polyhexamethylene guanidine hydrochloride with a relative molecular weight of 1800, 5kg of 4,4'-diphenylmethane-diisocyanate and disodium hydrogen sulfate 3kg, placed in a nitrogen atmosphere, at 110°C, 800 rpm, stirred for 4 hours;

[0033] (2) Add 30 kg of glyceryl stearate and 15 kg of calcium carbonate whiskers to the product of step (1), and mix uniformly to obtain a papermaking auxiliary composition.

[0034] Table 1 shows the performance test results of the prepared papermaking auxiliary composition.

Embodiment 3

[0036] (1) 30kg of polyoxypropyl glyceryl ether, 25kg of alkali-free glass fiber, 10kg of polyhexamethylene guanidine hydrochloride with a relative molecular weight of 1600, 4kg of 4,4'-diphenylmethane-diisocyanate, disodium hydrogen sulfate 5kg and 2kg of nano silicon dioxide, placed in a nitrogen atmosphere, at 90°C, 700 rpm, stirred for 3 hours;

[0037] (2) Add 20 kg of glyceryl stearate and 10 kg of calcium carbonate whiskers to the product of step (1), and mix uniformly to obtain a papermaking auxiliary composition.

[0038] Table 1 shows the performance test results of the prepared papermaking auxiliary composition.

[0039] Table 1

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com