Determination of trace impurity elements in high purity indium through glow discharge mass spectrometry method

A trace impurity, high-purity technology, applied in measuring devices, material analysis through electromagnetic means, instruments, etc., can solve the problems of cumbersome operation, long process, easy introduction of contamination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Sample pre-sputtering: put the sample into the sample holder, push it into the ion source cavity, wait until the vacuum reaches 2.2~2.4mbar, adjust the discharge voltage and discharge current to 0.9~1.2kV, 40~45mA, and sputter about 30 ~40min, generally based on the stable signals of Na, Fe and Ca, which are easy to introduce contamination, to eliminate possible contamination during sample preparation.

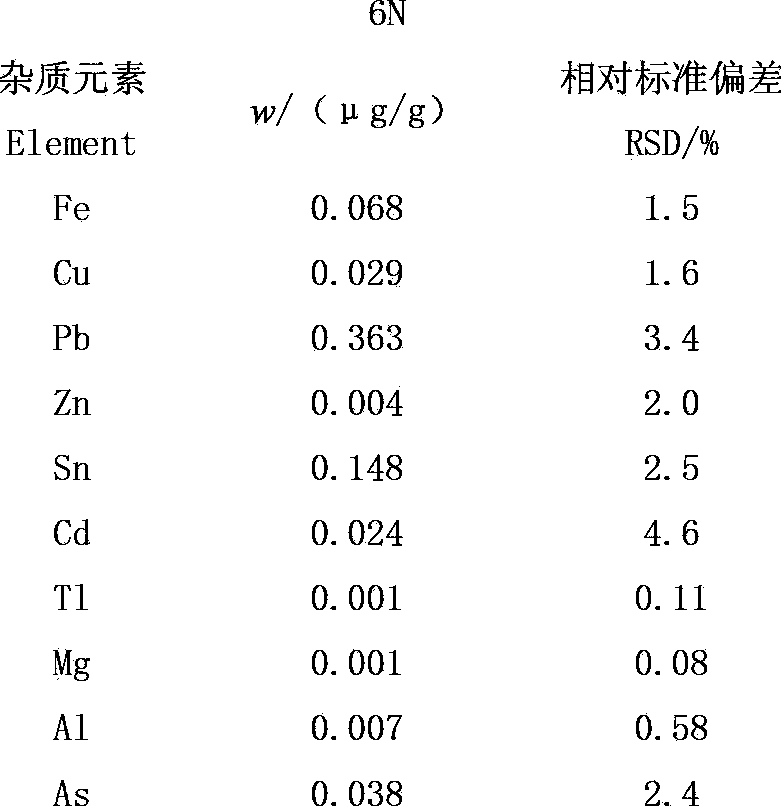

[0020] Quantitative determination: adjust the discharge voltage to 0.9-1.2kV, discharge current to 40-45mA, carry out high-voltage discharge, collect ion signals of the elements to be measured, and calculate the concentration of impurity elements to be measured according to the quantitative analysis principle of the glow discharge mass spectrometer. Table 1 shows the measurement results of high-purity indium (≥6N).

[0021] Table 1 Experimental results

[0022]

[0023] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com