Coal and gas outburst simulation system and method

A gas outburst and simulation system technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as difficult coal and gas mechanism research, safety threats, and inability to measure disturbance intensity and disturbance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

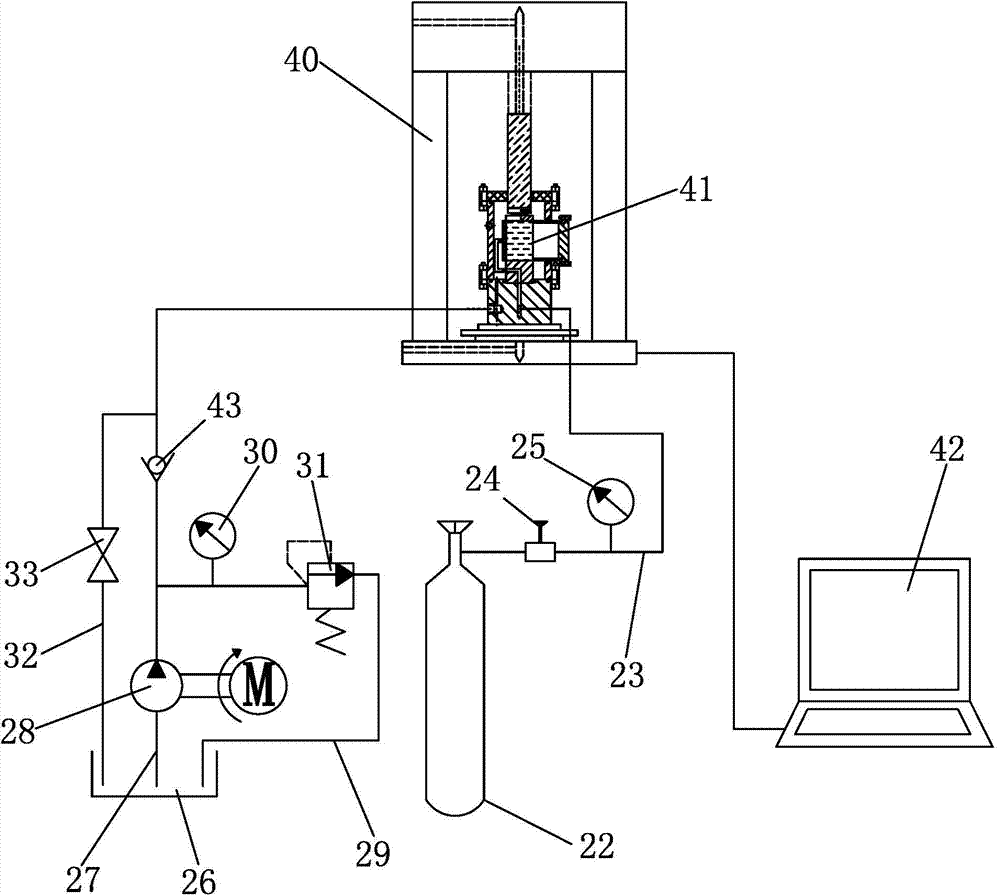

[0084] like figure 1 and figure 2As shown, a coal and gas outburst simulation system of the present invention includes an electronic universal testing machine 40, an outburst simulation device 41, a gas system, a confining pressure hydraulic system, and a computer 42. The outburst simulation device 41 is centrally placed on the electronic On the base of the universal testing machine 40, the electronic universal testing machine 40 is connected with the computer 42;

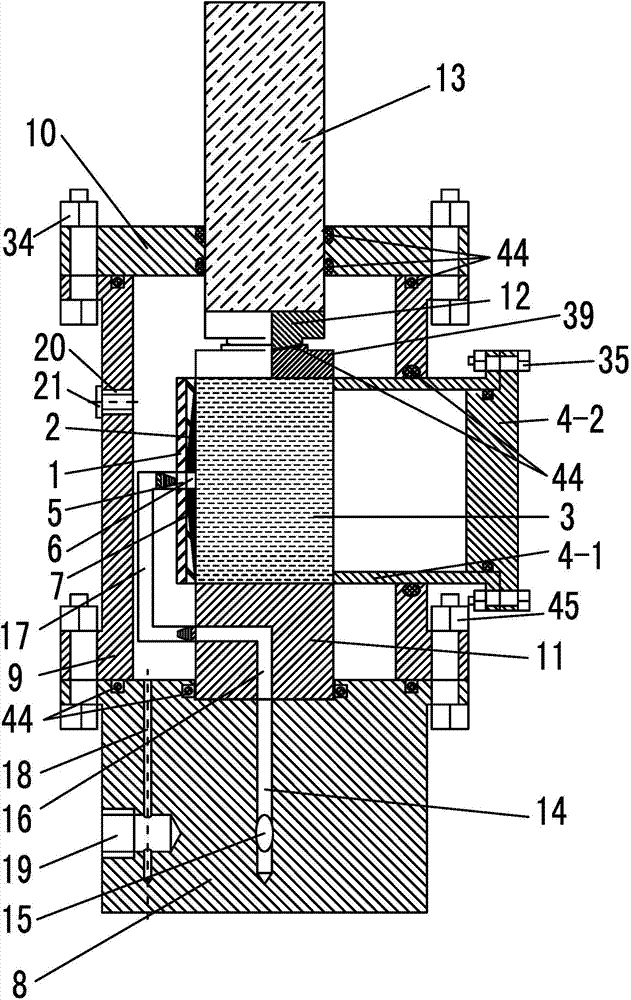

[0085] The protrusion simulation device 41 is composed of a roadside simulation mechanism and a roadside surrounding environment simulation mechanism. The roadside simulation mechanism includes a baffle plate 1, a ventilating plate 2, a coal rock sample 3 and a U-shaped ferrule that are sequentially connected. The baffle plate 1, the ventilation plate 2, the coal rock sample 3 and the U-shaped ferrule are fixed as a whole by electrical tape winding, and the U-shaped ferrule is detachably connected to one end of t...

Embodiment 2

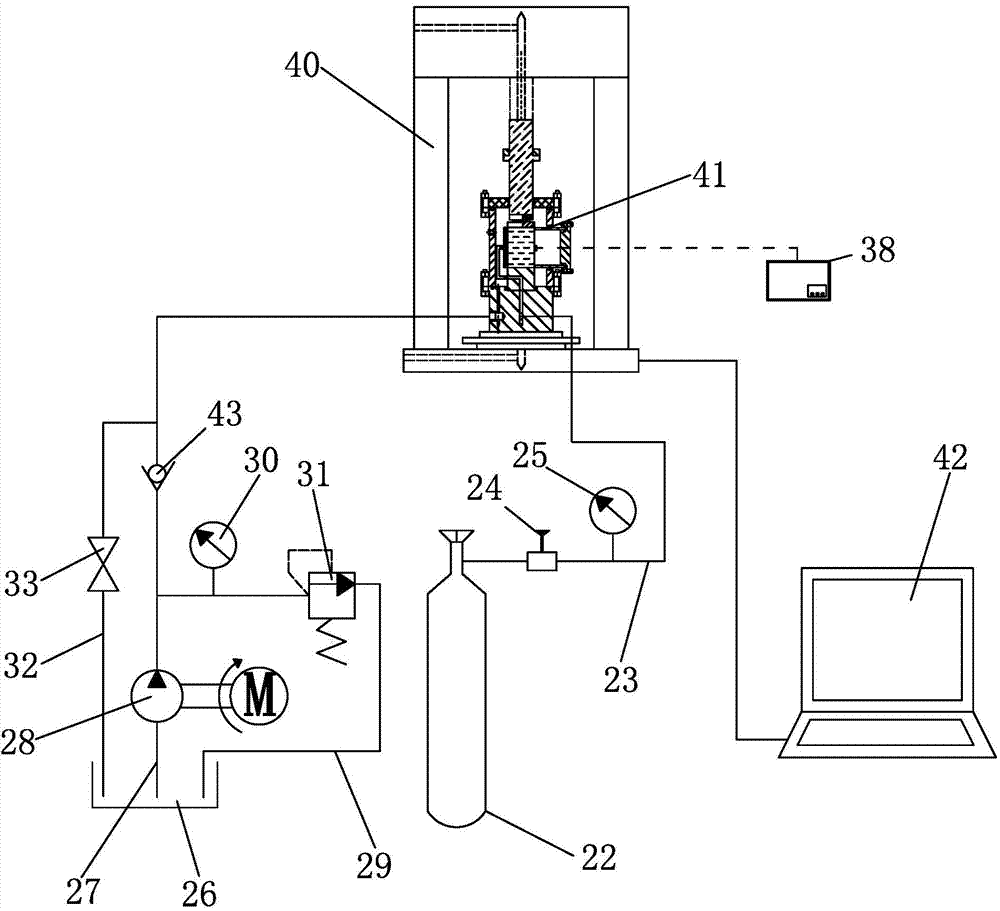

[0112] like image 3 and Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the present invention also includes a vibration detection device 38 for detecting the vibration intensity, and the vibration detection probe of the vibration detection device 38 is placed on the disassembled casing cover 4- 2 On the surface of the coal rock sample 3 exposed in the rear casing 4-1; the middle part of the piston 13 located outside the cylinder cover 10 is provided with an annular protrusion 36, and the piston 13 is sleeved with a ring located on the upper part of the annular protrusion 36. The perturbation ring 37. Specifically, the vibration detection device 38 is an ultra-dynamic signal test and analysis system modeled as DH5960. All the other structures are the same as in Example 1.

[0113] A method for simulating coal and gas outburst under the influence of disturbance using a coal and gas outburst simulation system in this embodiment includes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com