Blocked polyisocyanate water dispersion, fiber processing agent composition, and fabric

A polyisocyanate, fiber treatment agent technology, applied in fiber treatment, liquid repellent fibers, polyurea/polyurethane coatings, etc., can solve problems such as water repellency reduction, achieve excellent mechanical stability, high coating film strength, Good water dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

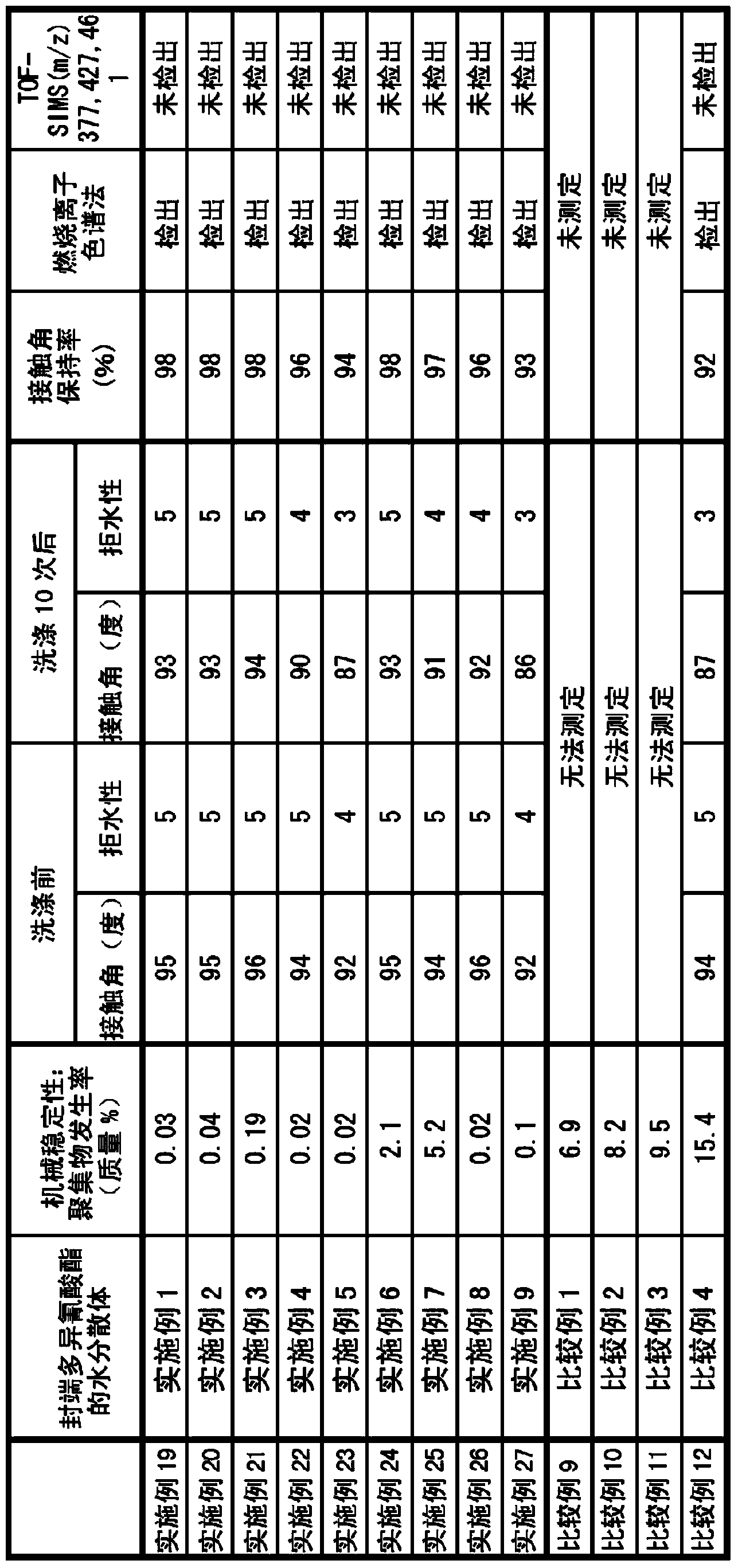

Examples

Embodiment

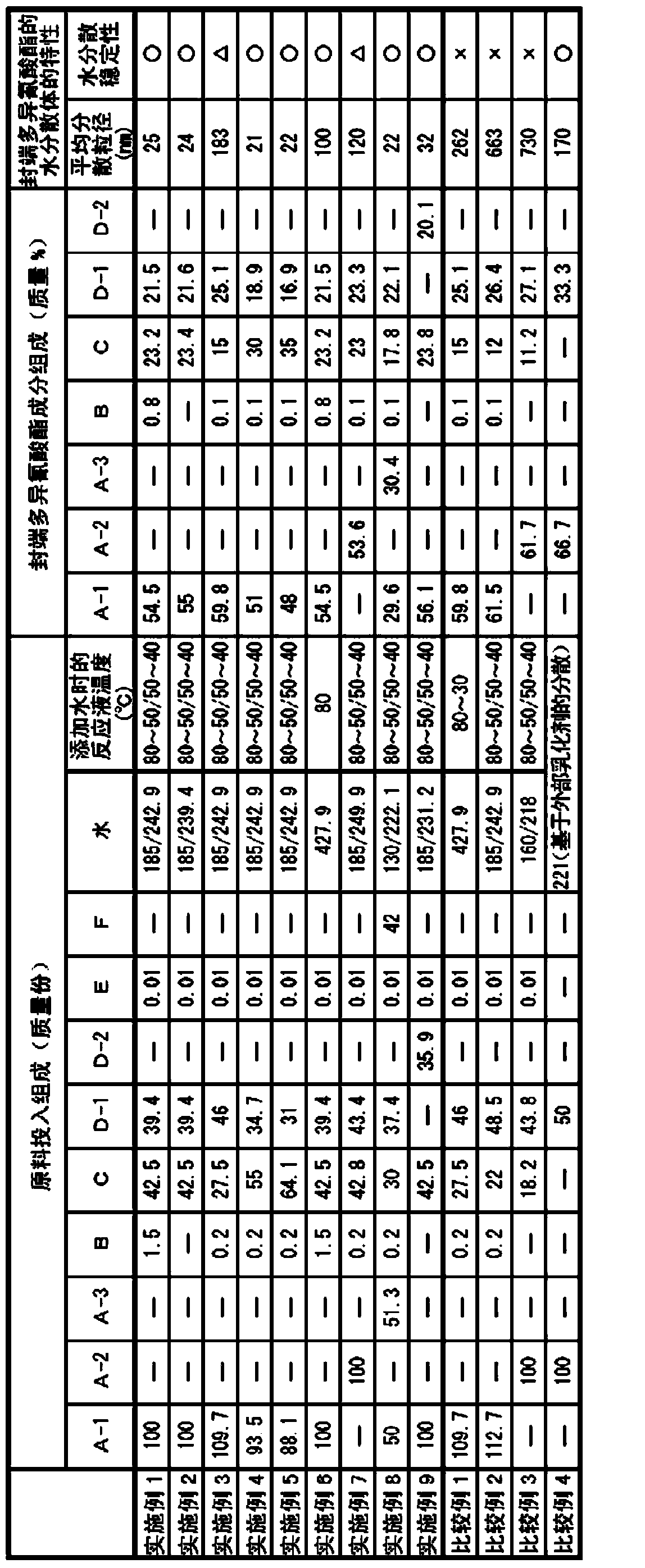

[0149] The present invention will be specifically described with reference to the following examples and the like, but the present invention is not limited to these.

[0150] (1) Viscosity measurement:

[0151] The viscosity was measured using the following device.

[0152] Device: RE-80R (manufactured by Toki Sangyo Co., Ltd.)

[0153] Rotor: Cone plate 1°34’×R24

[0154] Measuring temperature: 25℃

[0155] (2) Determination of number average molecular weight:

[0156] The number average molecular weight is a polystyrene standard number average molecular weight measured by gel permeation chromatography using the following apparatus.

[0157] Device: HLC-802A (manufactured by Tosoh Corporation)

[0158] Column: G1000HXL×1 (manufactured by Tosoh Corporation)

[0159] G2000HXL×1 (manufactured by Tosoh Corporation)

[0160] G3000HXL×1 (manufactured by Tosoh Corporation)

[0161] Carrier gas: Tetrahydrofuran

[0162] Flow rate: 0.6mL / min

[0163] Sample concentration: 1.0% by mass

[0164] Injection ...

manufacture example 1

[0221] (Production example 1: Production of polyisocyanate)

[0222] A 4-necked flask equipped with a stirrer, a thermometer, a reflux condenser, and a nitrogen blowing tube was made into a nitrogen atmosphere, and 1000 parts by mass of HDI and 22 parts by mass of trimethylolpropane (molecular weight 134) as a triol were put into the flask. Next, the temperature in the reactor was maintained at 90°C for 1 hour to carry out urethanization. After that, the temperature of the reaction solution was maintained at 60° C., the isocyanuration catalyst tetramethylammonium caprylate was added, and phosphoric acid was added when the conversion rate reached 48% to stop the reaction. Then, after filtering the reaction liquid, the unreacted HDI was removed by a thin film distillation apparatus.

[0223] The obtained polyisocyanate had a viscosity of 25,000 mPa·s at 25° C., an isocyanate group content of 19.9% by mass, a number average molecular weight of 1080, and an average number of isocyan...

manufacture example 2

[0224] (Production Example 2: Production of polyisocyanate)

[0225] A 4-necked flask equipped with a stirrer, a thermometer, a reflux condenser, a nitrogen blowing tube, and a dropping funnel was made into a nitrogen atmosphere, 1000 parts by mass of HDI was put into it, and the temperature in the reactor was kept at 70°C under stirring. Add isocyanuration catalyst tetramethylammonium caprylate, add phosphoric acid when the yield reaches 40%, and stop the reaction. After filtering the reaction liquid, use a thin film evaporator to remove unreacted HDI.

[0226] The obtained polyisocyanate had a viscosity of 2700 mPa·s at 25°C, an isocyanate content of 21.7%, a number average molecular weight of 660, and an average number of isocyanate functional groups of 3.4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Average dispersed particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com