Polymer inarching carbon nano-tube and method of manufacturing the same

A carbon nanotube and polymer technology, which is applied in the field of polymer-grafted carbon nanotubes and its preparation, can solve the problems of long preparation time, high cost and cumbersome process of modified carbon nanotubes, and achieves good solubility and polymerization. The effect of physical compatibility and good water dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1, preparation polytetrahydrofuran graft modified carbon nanotube

[0031] Step (a): Add 0.2 g of raw material carbon nanotubes into an Erlenmeyer flask filled with 40 ml of concentrated sulfuric acid and concentrated nitric acid (volume ratio 3:1), and then put it into an ultrasonic instrument for ultrasonication for 3 hours. After the ultrasound is over, pour a large amount of deionized water to dilute, and then use filter paper with a pore size of 220nm to filter. The solid above is washed with deionized water continuously until the extracted water is about neutral. Dry the solid in a vacuum oven to obtain acidified carbon nanotubes.

[0032] Step (b): Add 0.2 g of the acidified carbon nanotubes obtained in step (a) into 50 ml of freshly steamed thionyl chloride and heat to reflux for 24 hours to convert the carboxyl groups on the surface of the carbon nanotubes into acid chlorides. The product was filtered through a cellulose filter paper with a pore siz...

Embodiment 2

[0035] Example 2: Preparation of polyepichlorohydrin graft modified carbon nanotubes and polyepichlorohydrin methyl imidazolium salt graft modified carbon nanotubes

[0036] Step (a): The preparation of acidified carbon nanotubes is the same as step (a) of Example 1.

[0037] Step (b): The preparation of acylated carbon nanotubes is the same as step (b) of Example 1.

[0038] Step (c): replace tetrahydrofuran in step (c) of Example 1 with epichlorohydrin, and keep other processes unchanged to obtain polyepichlorohydrin graft-modified carbon nanotubes.

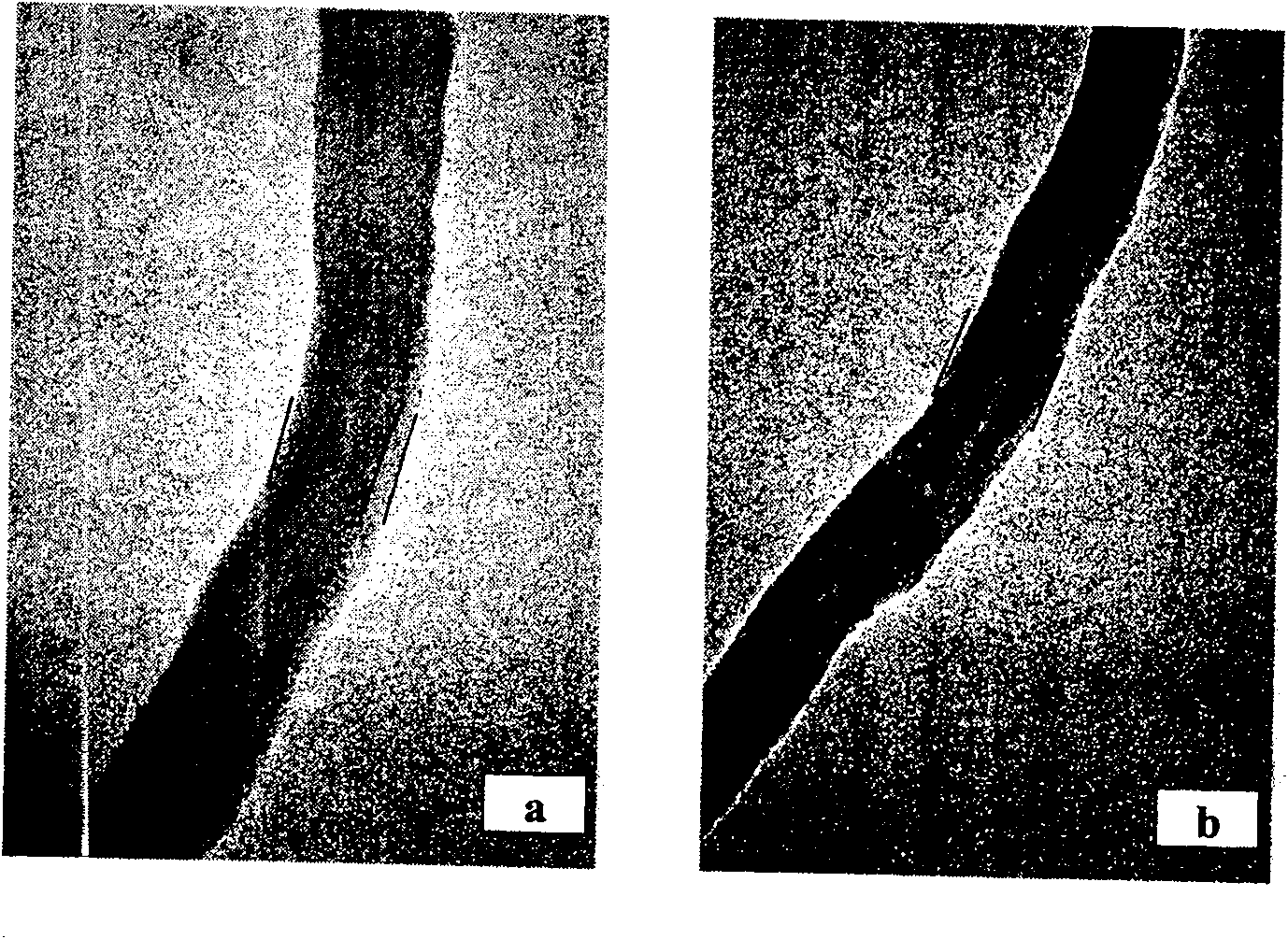

[0039] Its transmission electron microscope pictures are as figure 1 as shown in a.

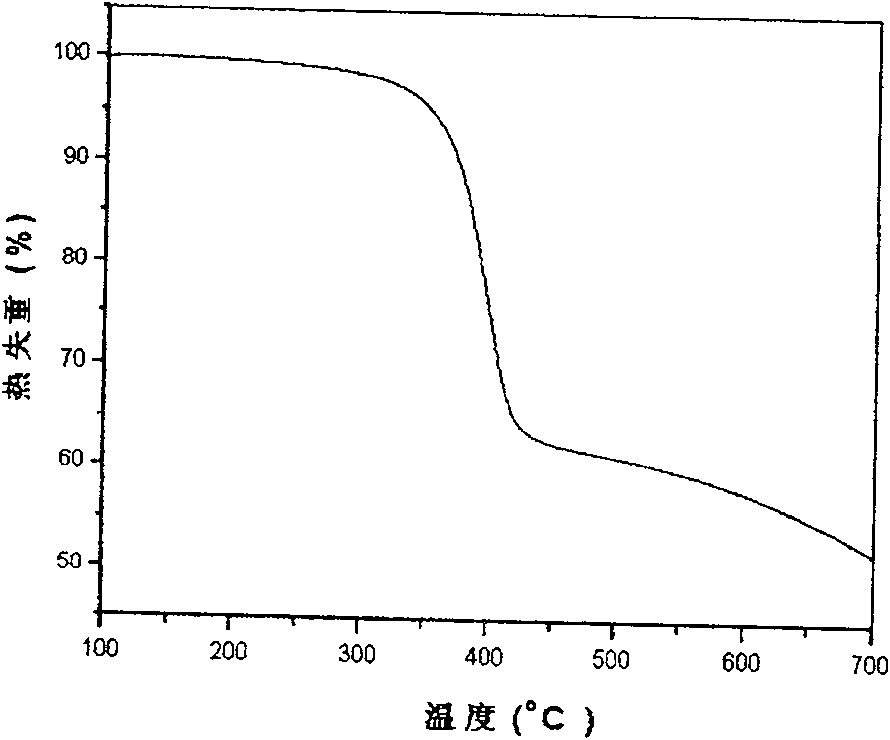

[0040] Its thermogravimetric analysis diagram is shown in figure 2 As shown, the results indicated that the polymer grafting amount was 40%.

[0041]Step (d): Add 0.2 g of polyepichlorohydrin graft-modified carbon nanotubes obtained in step (c) to 30 ml of 95% ethanol, and then add 10 ml of methylimidazole. Adding reflux and electromagne...

Embodiment 3

[0043] Embodiment 3: Preparation of polypropylene oxide graft-modified carbon nanotubes

[0044] Step (a): The preparation of acidified carbon nanotubes is the same as step (a) of Example 1.

[0045] Step (b): The preparation of acylated carbon nanotubes is the same as step (b) of Example 1.

[0046] Step (c): replace tetrahydrofuran in step (c) of Example 1 with propylene oxide, and keep other processes unchanged to obtain the target product polypropylene oxide graft-modified carbon nanotubes. The result of thermogravimetric analysis shows that the polymer grafting amount is about 45%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com