Up-flow type coupling hydrolysis acidification pool

A hydrolytic acidification tank and flow-type technology, applied in anaerobic digestion treatment, etc., can solve the problems of high biomass, unmaintainable, poor mud-water separation efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific diagrams.

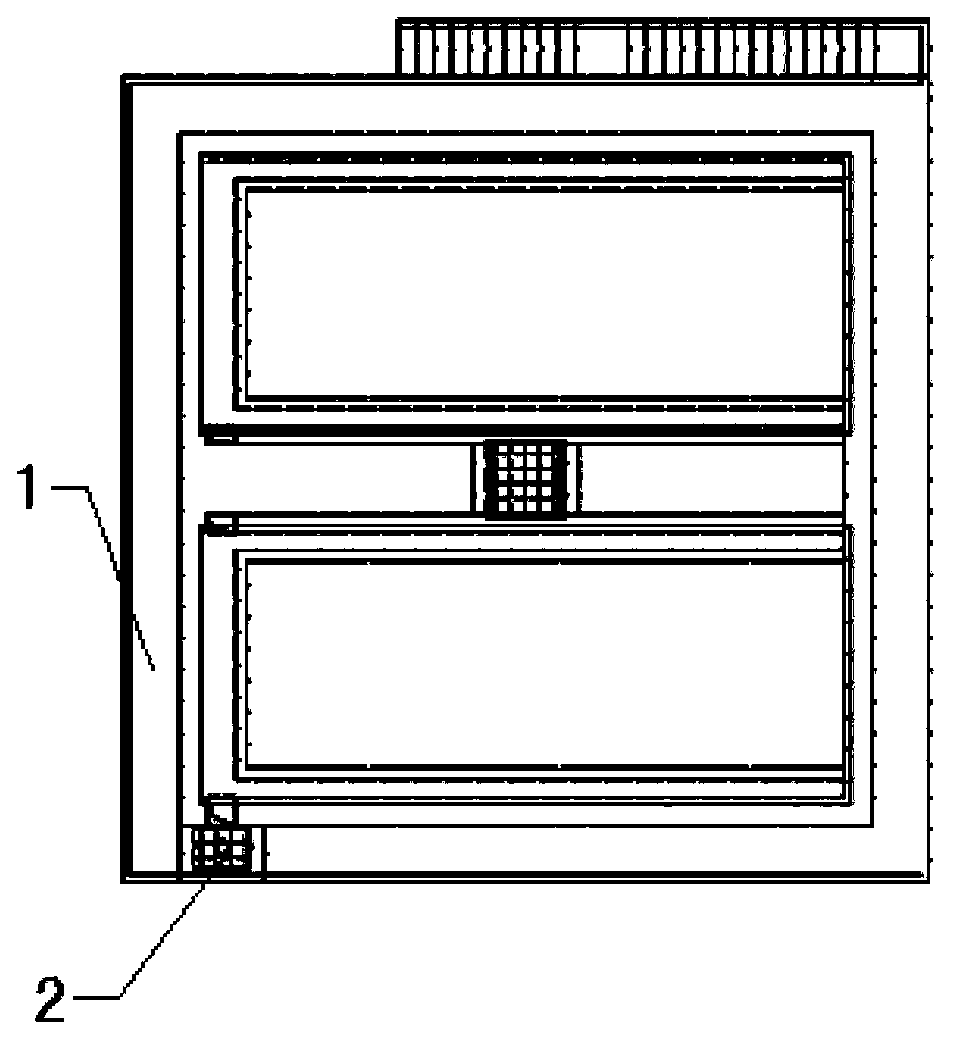

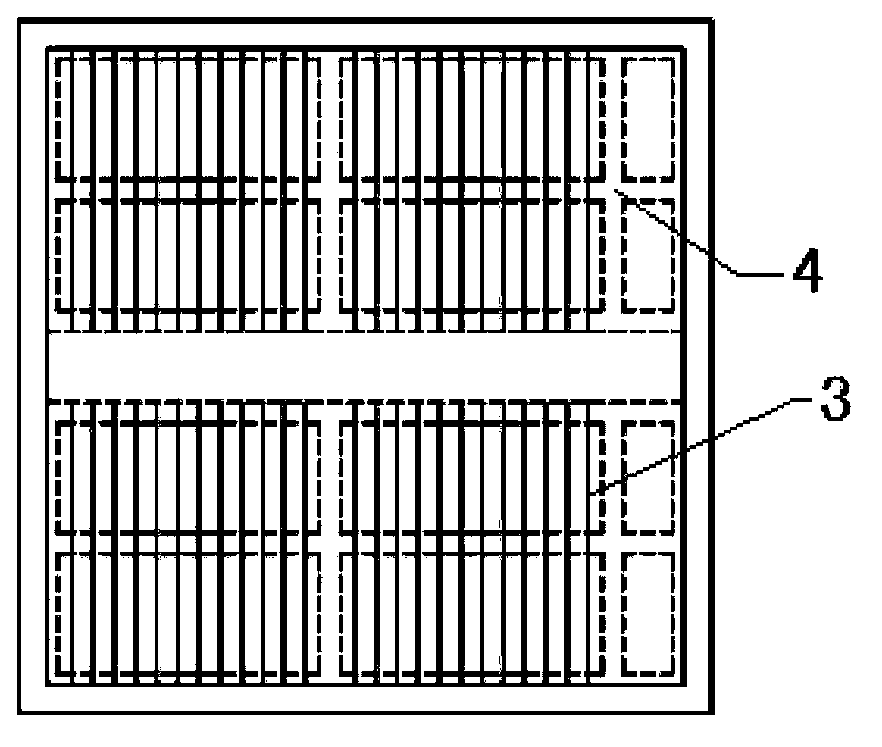

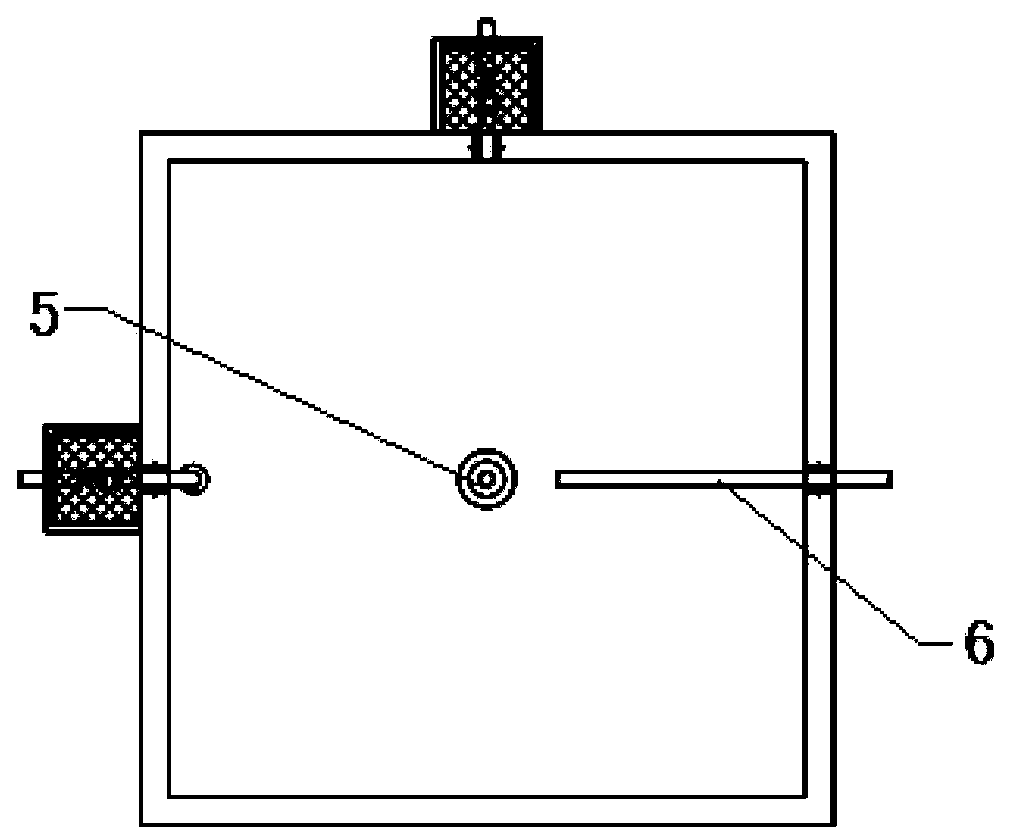

[0019] refer to figure 1 , figure 2 , image 3 and Figure 4 , an upflow coupled hydrolysis acidification tank, including a hydrolysis acidification tank, the hydrolysis acidification tank is followed by a clarification zone, a coupling precipitation reaction zone, and a sludge bed reaction zone from top to bottom, and a stirrer is arranged in the hydrolysis acidification tank, and the stirrer is Submersible mixer 5, the submersible mixer 5 is placed at the bottom of the hydrolysis acidification tank, located in the sludge bed reaction zone. Under the action of the submersible mixer 5, the sludge in the sludge bed reaction zone is quickly and evenly mixed. The sludge bed is similar to a filter layer, which quickly traps and absorbs the particulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com