Soil curing agent

A technology of soil stabilizer and magnesium chloride, which is applied in the field of engineering materials, can solve the problems of industrial waste pollution and low production cost, and achieve the effects of solving pollution, reducing production cost and improving construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

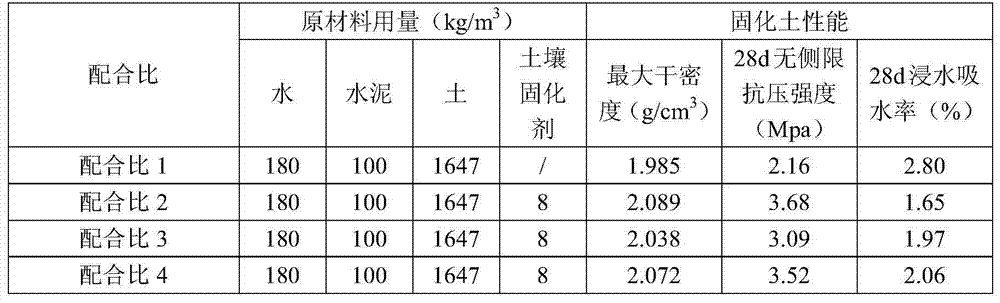

Examples

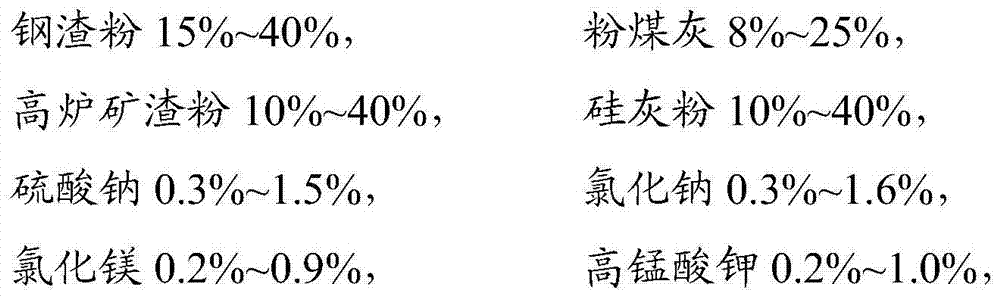

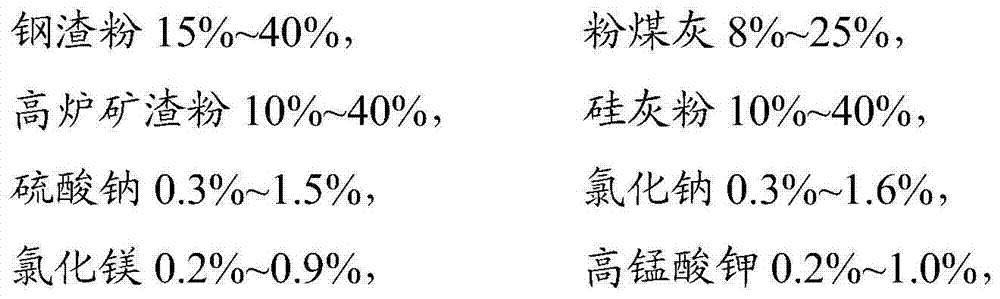

Embodiment 1

[0019] Take by weighing 280kg steel slag powder, 220kg fly ash, 300kg blast furnace slag powder, 160kg silica fume powder, 8kg sodium sulfate, 12kg sodium chloride, 7kg magnesium chloride, 5kg potassium permanganate, and 8kg sodium dodecylbenzenesulfonate, After mixing evenly, grind it through a ball mill until the Blaine specific surface area is 300m 2 / kg of powder, and then the powder is stirred at a medium speed for 30s at a stirring speed of 300r / min to obtain the soil curing agent of the present invention.

Embodiment 2

[0021] Take by weighing 250kg steel slag powder, 250kg fly ash, 330kg blast furnace slag powder, 140kg silica fume powder, 5kg sodium sulfate, 10kg sodium chloride, 4kg magnesium chloride, 5kg potassium permanganate, and 6kg sodium dodecylbenzenesulfonate, After mixing evenly, grind it through a ball mill until the Blaine specific surface area is 650m 2 / kg of powder, and then the powder is stirred at a medium speed for 35s at a stirring speed of 350r / min to obtain the soil curing agent of the present invention.

Embodiment 3

[0023] Take by weighing 240kg steel slag powder, 240kg fly ash, 280kg blast furnace slag powder, 200kg silica fume powder, 12kg sodium sulfate, 11kg sodium chloride, 6kg magnesium chloride, 4kg potassium permanganate, and 7kg sodium dodecylbenzenesulfonate, After mixing evenly, grind it through a ball mill until the Blaine specific surface area is 1000m 2 / kg of powder, and then the powder is stirred at a medium speed for 40s at a stirring speed of 400r / min to obtain the soil curing agent of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com