Environment-friendly multifunctional grouting agent

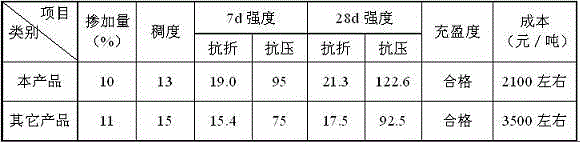

A multi-functional, grouting agent technology, applied in the field of grouting agent, can solve the problems of large bleeding of freshly mixed slurry, poor adaptability between cement and water reducing agent, poor fluidity, etc., to reduce the standard consistency of cement, physical Significant water reduction effect and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

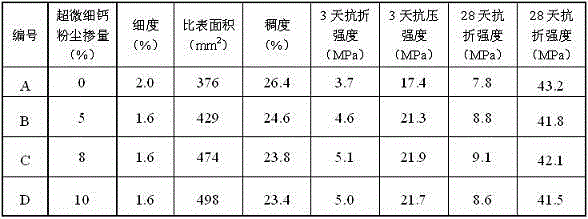

[0026] Example 1 Environmentally friendly multifunctional grouting agent, which is prepared by mixing the following raw materials uniformly: 1.2g sodium dodecylbenzenesulfonate, 0.4g carboxymethyl cellulose, 24g high-performance water reducer powder, granulated blast furnace 13.2g of slag powder, 37.8g of steel slag powder, 39.6g of desulfurized gypsum, 94.6g of high calcium fly ash, and 90g of ultrafine calcium dust.

Embodiment 2

[0027] Example 2 Environmentally friendly multifunctional grouting agent, which is prepared by mixing the following raw materials uniformly: 1.6g sodium dodecylbenzenesulfonate, 0.5g carboxymethyl cellulose, 22g high-performance water reducer powder, granulated blast furnace Slag powder 13.6g, steel slag powder 39.0g, desulfurization gypsum 40.8g, high calcium fly ash 90.8g, ultrafine calcium dust 95g.

Embodiment 3

[0028] Example 3 Environmentally friendly multifunctional grouting agent, which is prepared by mixing the following raw materials evenly: 2.0g sodium dodecylbenzenesulfonate, 0.6g carboxymethyl cellulose, 20g high-performance water reducer powder, granulated blast furnace 14.0g of slag powder, 40.2g of steel slag powder, 42.0g of desulfurized gypsum, 87.0g of high calcium fly ash, and 100g of ultrafine calcium dust.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com