A kind of refractory castable for molten salt chlorination furnace and its preparation method and application

A refractory castable and molten salt chlorination furnace technology, applied in the field of refractory materials, can solve the problems of poor clay corrosion resistance against molten salt, accelerated molten salt erosion of clay, salt leakage from molten salt chlorination furnace, etc. The molten salt has good erosiveness, ensures stable continuous production, and has the effect of good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention also provides a preparation method of the refractory castable, which may include corundum, mullite, water reducer, binder, α-Al 2 o 3 Micropowder and hardening additives are mixed, preferably, the method also includes corundum, mullite, water reducer, binder, α-Al 2 o 3 Micronized powder, hardening additives and silica fume are mixed.

[0025] According to the preparation method provided by the present invention, the consumption of each component can be adjusted according to actual needs. In order to make the performance of the prepared refractory castable better, preferably, the consumption of each component is based on the total weight of the obtained refractory castable , the content of the corundum is 50-80% by weight, the content of the mullite is 1-10% by weight, the content of the water reducing agent is 0.01-0.2% by weight, and the content of the binder is 10-30% by weight, The α-Al 2 o 3 The content of the fine powder is 1-10% by weig...

Embodiment 1

[0036] This example is used to illustrate the preparation of the refractory castable provided by the present invention.

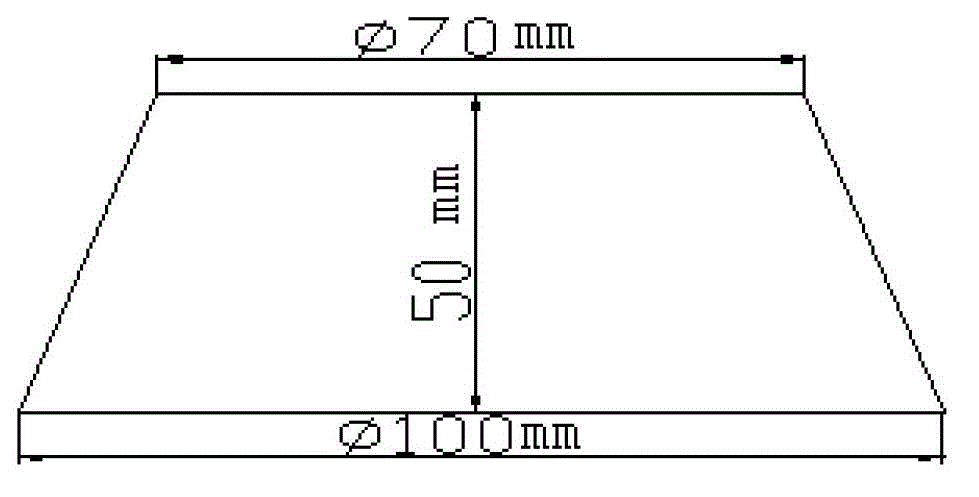

[0037] First, corundum is ground to three different particle sizes of 8mm, 3mm, and 0.08mm, and mullite is ground to a particle size of 1mm. Based on the total weight of the refractory castable to be prepared, each raw material is 24% by weight of 8mm corundum, 24% by weight of 3mm corundum, 15% by weight of 0.08mm corundum, 5% by weight of mullite, 5% by weight of silica fume, α-Al 2 o 3 Micropowder 5% by weight, sodium tripolyphosphate 0.1% by weight, aluminum dihydrogen phosphate (bulk density 1.35g / cm 3 ) 6.5% by weight to obtain a mixture, the mixture is trapped for 24 hours, and then the mixture after trapping is mixed with pure calcium aluminate cement 2.5% by weight and aluminum dihydrogen phosphate (volume density is 1.35g / cm 3 ) 12.9% by weight for mixing, which is the refractory castable for molten salt chlorination furnace.

Embodiment 2

[0039] This example is used to illustrate the preparation of the refractory castable provided by the present invention.

[0040] First, corundum is ground to three different particle sizes of 7mm, 2mm, and 0.08mm, and mullite is ground to a particle size of 1mm. Based on the total weight of the refractory castable to be prepared, the raw materials are divided into 24% by weight of 7mm corundum, 24% by weight of 2mm corundum, 20% by weight of 0.08mm corundum, 5% by weight of mullite, α-Al 2 o 3 Micropowder 5% by weight, sodium tripolyphosphate 0.1% by weight, aluminum dihydrogen phosphate (bulk density 1.35g / cm 3 ) of 6.8% by weight to obtain a mixture, the mixture is trapped for 24 hours, and then the mixture after trapping is mixed with pure calcium aluminate cement 2.1% by weight and aluminum dihydrogen phosphate (volume density is 1.35g / cm 3 ) 13% by weight for mixing, which is the refractory castable for molten salt chlorination furnace.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com