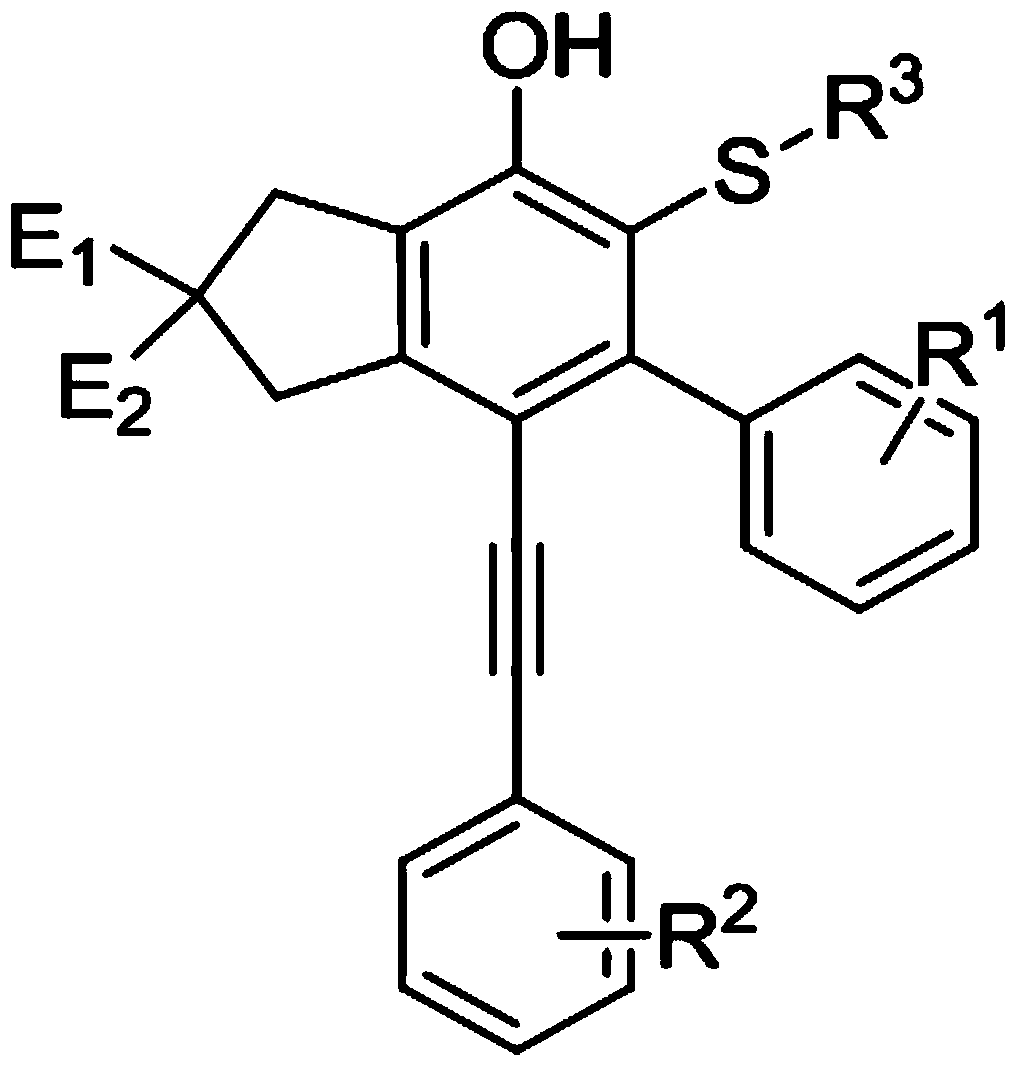

O-mercapto phenol derivatives and preparation method thereof

A technology of ortho-mercaptophenol derivatives, which is applied in the field of preparation of ortho-mercaptophenol derivatives, can solve the problems of low yield, high cost, and few researches on preparation methods of mercaptophenol derivatives, and achieve broad application prospects , complex and diverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

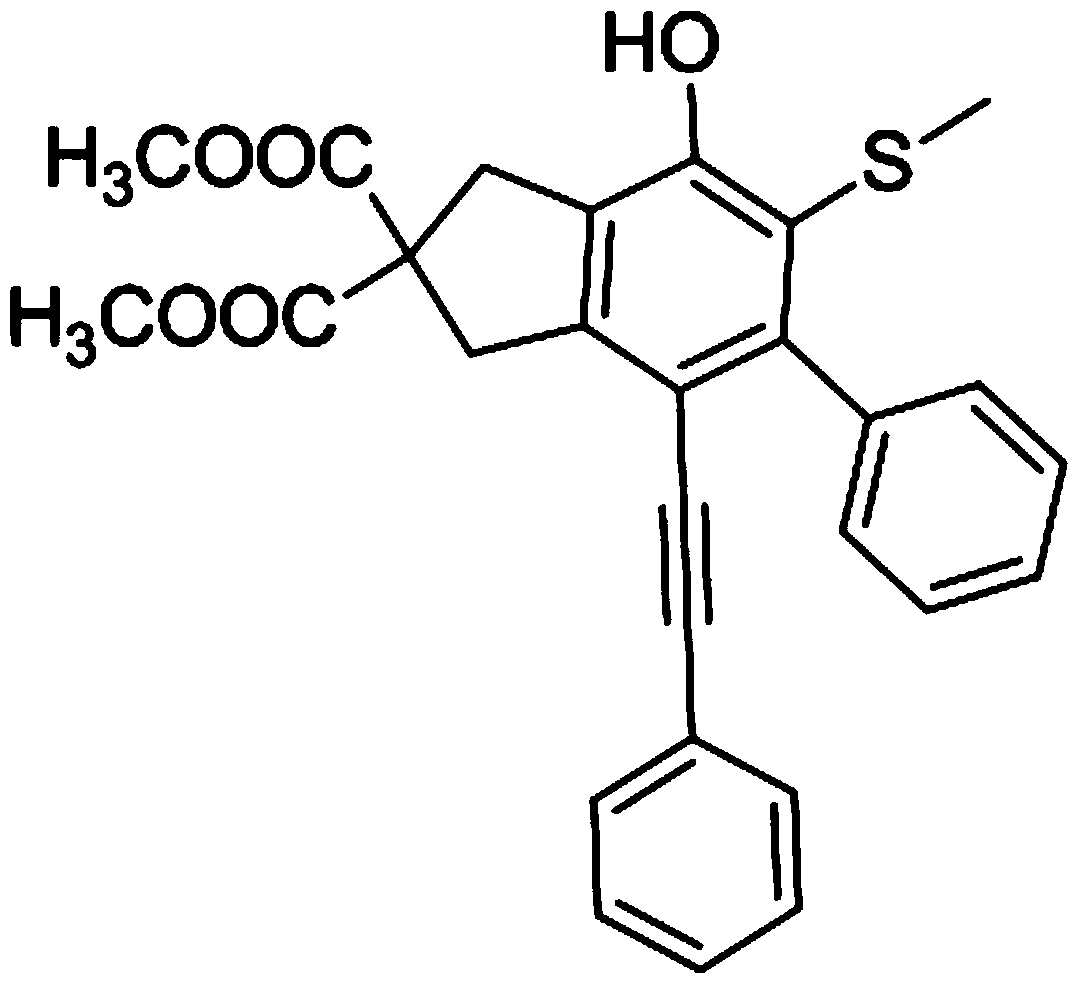

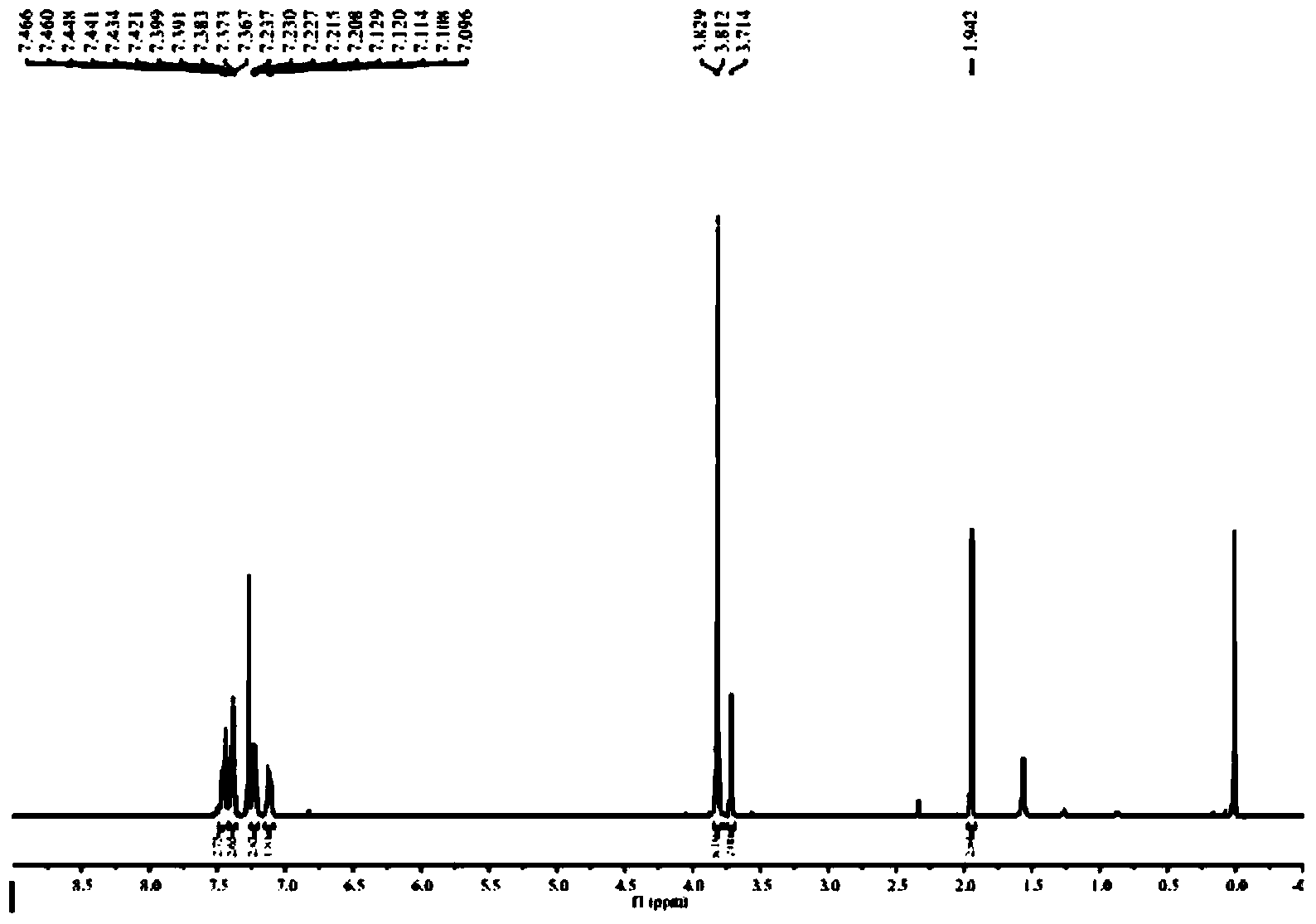

Embodiment 1

[0062] A kind of ortho mercaptophenol derivative, its structure is as follows:

[0063]

[0064] A kind of above-mentioned ortho mercaptophenol derivative, its preparation method comprises the following steps:

[0065] a. Precursor compound synthesis:

[0066] (1) Using sodium hydride (400mmol) as a catalyst, dimethyl malonate (200mmol) and propargyl bromide (440mmol) were added to anhydrous acetonitrile and stirred in an ice-water bath for 8 hours, and the reaction product was washed with water and used Extracted with ethyl acetate, spin-dried under reduced pressure, column chromatography (volume ratio ethyl acetate:petroleum ether=1:100) to obtain a white solid product, wherein the molar ratio of dimethyl malonate to propargyl bromide was 1:2.2 .

[0067] (2) The white solid product (80mmol) was mixed with phenylethynyl bromide in Pd(PPh 3 ) 2 Cl 2 : In the anhydrous and oxygen-free catalytic system of CuI=(3:1), triethylamine is used as a base, anhydrous acetonitril...

Embodiment 2

[0077] A kind of ortho mercaptophenol derivative, its structure is as follows:

[0078]

[0079] A kind of above-mentioned ortho mercaptophenol derivative, its preparation method comprises the following steps:

[0080] a. Precursor compound synthesis:

[0081] (1) Using sodium hydride (400mmol) as a catalyst, diethyl malonate (200mmol) and propargyl bromide (440mmol) were added to anhydrous acetonitrile and stirred in an ice-water bath for 8 hours, and the reaction product was washed with water and used Extracted with ethyl acetate, spin-dried under reduced pressure, column chromatography (volume ratio ethyl acetate:petroleum ether=1:100) to obtain a white solid product, wherein the molar ratio of diethyl malonate to propargyl bromide was 1:2.2 ;

[0082] (2) The white solid product (80mmol) was mixed with phenylethynyl bromide in Pd(PPh 3 ) 2 Cl 2 : In the anhydrous and oxygen-free catalytic system of CuI (3:1), with triethylamine as base, with anhydrous acetonitrile ...

Embodiment 3

[0092] A kind of ortho mercaptophenol derivative, its structure is as follows:

[0093]

[0094] A kind of above-mentioned ortho mercaptophenol derivative, its preparation method comprises the following steps:

[0095] a. Precursor compound synthesis:

[0096] (1) Using sodium hydride (400mmol) as a catalyst, dipropyl malonate (200mmol) and propargyl bromide (440mmol) were added to anhydrous acetonitrile and stirred in an ice-water bath for 8 hours, and the reaction product was washed with water and used Extracted with ethyl acetate, spin-dried under reduced pressure, column chromatography (volume ratio ethyl acetate:petroleum ether=1:100) to obtain a white solid product, wherein the molar ratio of dipropyl malonate to propargyl bromide was 1:2.2 .

[0097] (2) The white solid product (80mmol) was mixed with phenylethynyl bromide in Pd(PPh 3 ) 2 Cl 2 : In the anhydrous and oxygen-free catalytic system of CuI (3:1), with triethylamine as base, with anhydrous acetonitril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com