Micro-nano multilayer polymer geomembrane as well as preparation method and device thereof

A micro-nano multi-layer, polymer technology, applied in the field of polymer materials, can solve the problems of geomembrane puncture, polymer geomembrane anti-seepage, decline in leak-proof performance, harsh environment for polymer geomembrane, etc. Low cost, suitable for industrial production, excellent puncture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1 of the present invention: Micro-nano multi-layer polymer geomembrane, calculated by weight, includes 80 parts of polyethylene, 23 parts of calcium carbonate and 2 parts of polyethylene grafted maleic anhydride.

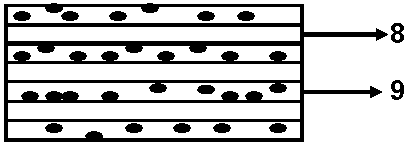

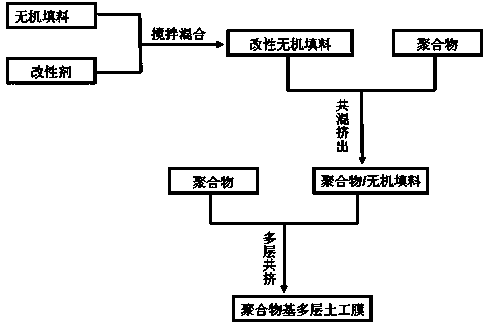

[0018] The preparation method of the micro-nano multi-layer polymer geomembrane, according to the above weight parts, firstly mix the calcium carbonate and the modifying agent, and then obtain the modified calcium carbonate and the modified calcium carbonate after stirring; then the modified calcium carbonate and the polyethylene Add it to a special polymer micro-nano lamination co-extrusion device for blending and extrusion to obtain alternating PE layers 8 and PE / CaCO 3 Finished layer 9; PE layer 8 or PE / CaCO 3 Layer 9 has a monolayer thickness of 50 nm.

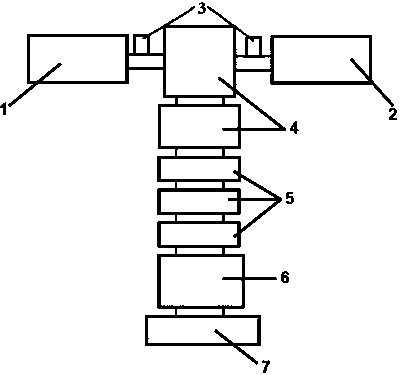

[0019] The special polymer micro-nano layered co-extrusion device includes a four-layer distributor 4, and the left single-screw extruder 1 and the right single-screw extruder 2 are respective...

Embodiment 2

[0020] Embodiment 2 of the present invention: Micro-nano multi-layer polymer geomembrane, calculated in parts by weight, includes 83 parts of polyethylene, 15 parts of inorganic filler and 2 parts of polyethylene grafted glycidyl methacrylate; the inorganic filler is High quality calcium carbonate and talcum powder are compounded.

[0021] The preparation method is the same as in Example 1 to obtain alternating PE layers 8 and PE / CaCO 3 / Finished product of talc layer 9; PE layer 8 or PE / CaCO 3 / The thickness of a single layer of the talc layer 9 is 200 nm.

[0022] The device that adopts is with embodiment 1.

Embodiment 3

[0023] Example 3 of the present invention: micro-nano multi-layer polymer geomembrane, calculated by weight, including 80 parts of EVA, 23 parts of montmorillonite and 2 parts of polyethylene grafted glycidyl methacrylate.

[0024] The preparation method is the same as that in Example 1, and the finished product of alternating EVA layer 8 and EVA / montmorillonite layer 9 is obtained; the single-layer thickness of EVA layer 8 or EVA / montmorillonite layer 9 is 150 nm.

[0025] The device that adopts is with embodiment 1.

[0026] In order to verify the effect of the present invention, the main mechanical properties of the single-layer and 1024-layer multilayer geomembranes of the products prepared in the above three examples are tested, and the tensile properties are tested according to the national standard GB / T 1040.3-2006, The puncture performance is tested according to ASTM D4833-2007. The results are shown in Table 1.

[0027]

[0028] According to the results of Table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com