Method and device for extracting chlorella oil by virtue of wet method

A technology of chlorella and oil, which is applied in the direction of fat oil/fat production and fat production, can solve the problems of low organic solvent extraction rate and large solvent loss, and achieve the effects of saving heat, increasing extraction rate, and reducing the amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

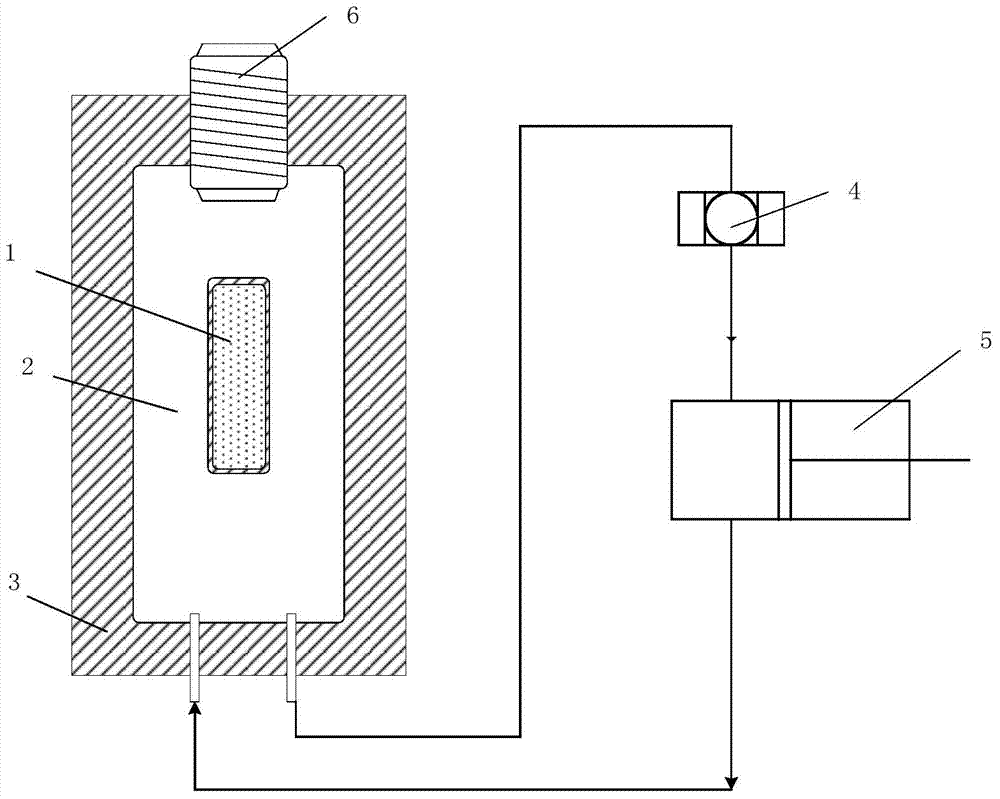

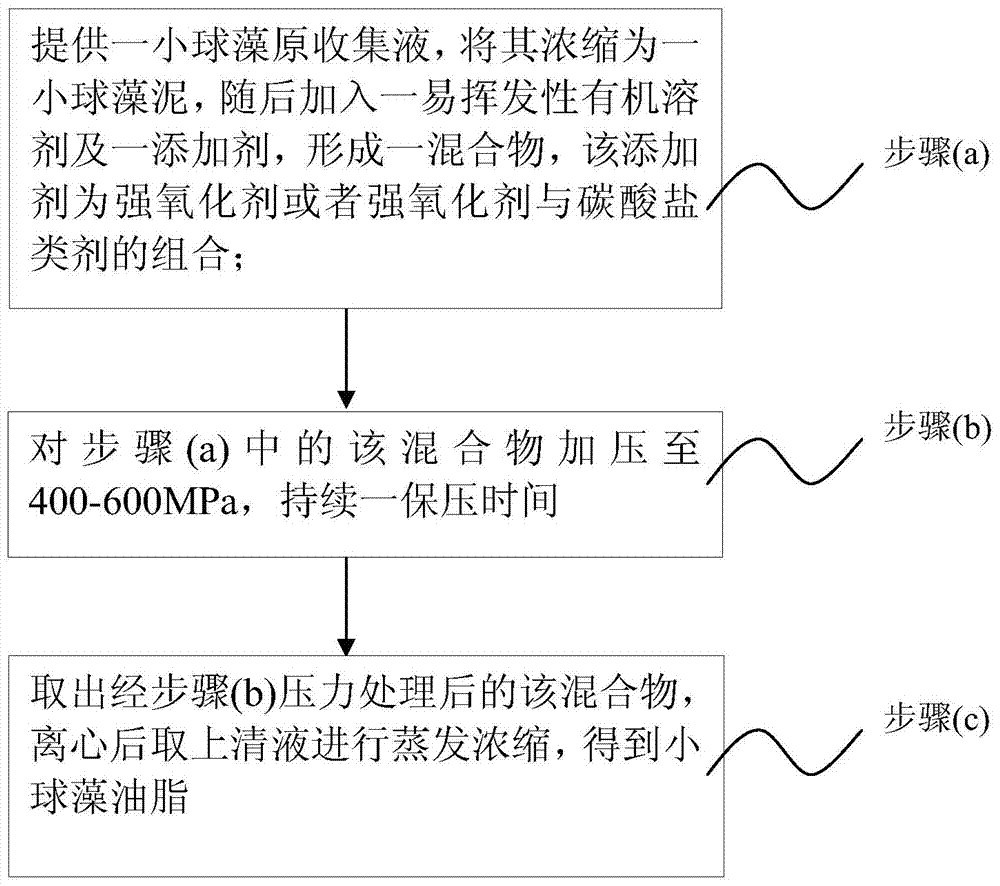

Method used

Image

Examples

Embodiment 1

[0064] Put 100g (about 100mL) of chlorella mud 1 with a water content of 80% obtained by flocculation and concentration into a packaging bag, add 0.2mL of concentrated sulfuric acid, 0.05g of sodium carbonate, 50mL of chloroform, and 100mL of methanol, exhaust, and seal. Put the packaging bag into the container 3, increase the pressure to 600MPa, and keep the pressure for 600S. After taking it out, put it into a centrifuge tube, and centrifuge at 4500r / min for 18min. Pour the supernatant into a separatory funnel, add 50 mL of chloroform, shake well, and let stand for 3 h. The lower aqueous layer was discarded, and the supernatant was subjected to reduced-pressure rotary evaporation, and the chlorella oil obtained by wet extraction was obtained after the concentration was completed.

Embodiment 2

[0066] Put 100g (about 100mL) of chlorella mud 1 with a water content of 75% obtained by flocculation and concentration into a packaging bag, add 0.1mL of concentrated sulfuric acid, 0.1mL of perchloric acid, 0.05g of sodium carbonate, add 160mL of petroleum ether, and 100mL of methanol, drain Air, seal. Put the packaging bag into the container 3, increase the pressure to 400MPa, hold the pressure for 200S, increase the pressure to 500MPa, hold the pressure for 200S, and release the pressure. After taking it out, put it into a centrifuge tube and centrifuge at 3000r / min for 5min. Pour the supernatant into a separatory funnel, discard the lower water layer, take the supernatant and carry out rotary evaporation under reduced pressure, and the chlorella oil extracted by wet method is obtained after the concentration is completed.

Embodiment 3

[0068] Put 100g (about 100mL) of chlorella mud with a water content of 80% obtained by flocculation and concentration into a packaging bag, add 0.1mL of concentrated sulfuric acid, add 50mL of chloroform, and 100mL of methanol, exhaust, and seal. Put the packaging bag into the container 3, increase the pressure to 400MPa, and keep the pressure for 1200S. After taking it out, put it into a centrifuge tube, and centrifuge at 4500r / min for 18min. Pour the supernatant into a separatory funnel, add 50 mL of chloroform, shake well, and let stand for 3 h. The lower aqueous layer was discarded, and the supernatant was subjected to reduced-pressure rotary evaporation, and the chlorella oil obtained by wet extraction was obtained after the concentration was completed.

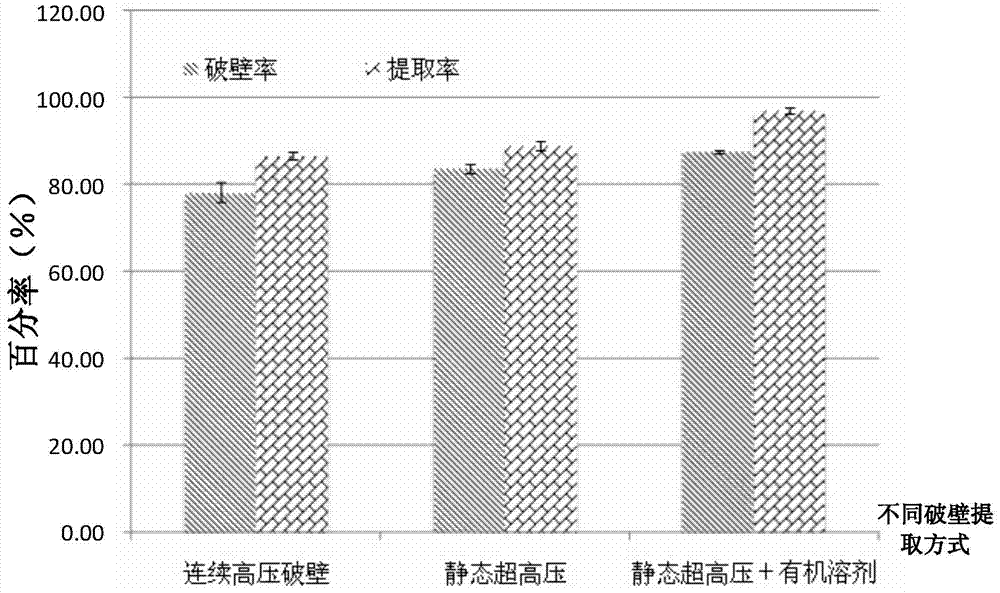

[0069] Compared with prior art, the present invention has following characteristics:

[0070] 1. There is no need to dry the chlorella, which saves a lot of heat.

[0071] 2. Microalgae cells generally have the proble...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com