Bio enzyme preparation for improvement of paper forming strength of alkaline peroxide mechanical pulp (APMP) and application thereof

A hydrogen peroxide and bio-enzyme technology, applied in the field of papermaking, can solve the problems of reducing the paper strength of pulp, reducing the bonding force between fibers, and insufficient paper strength, and achieve the effect of increasing the bonding force and improving the paper strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

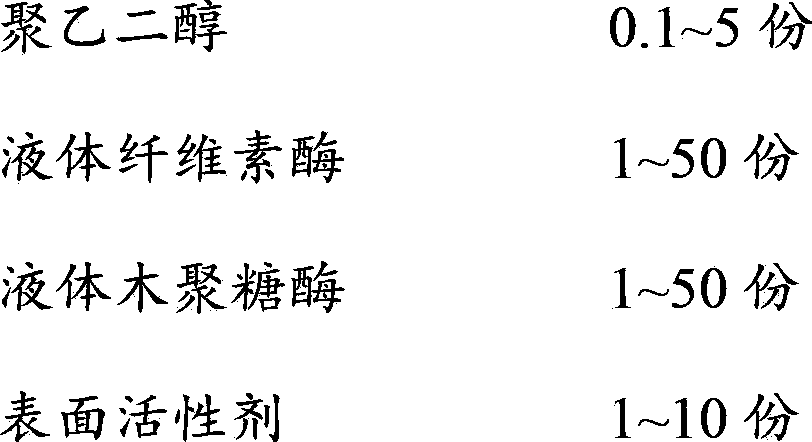

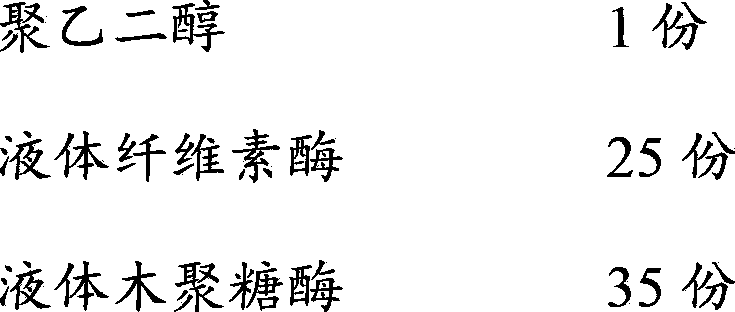

[0029] In a 250mL stainless steel container, add 34g of deionized water, 5g of polyoxyethylene stearate (40) ether, 1g of polyethylene glycol, 25g of liquid cellulase with an enzyme activity of 800U / ml, and 35g of liquid cellulase with an enzyme activity of 500,000U / ml. ml of liquid xylanase, mixed and stirred evenly to obtain a yellow-brown uniform liquid, which is the biological enzyme preparation for improving the paper strength of alkaline hydrogen peroxide mechanical pulp of the present invention.

Embodiment 2

[0031] In a 250mL stainless steel container, add 44.9g of deionized water, 5g of polyoxyethylene stearate (40) ether, 0.1g of polyethylene glycol, 10g of liquid cellulase with an enzyme activity of 800U / ml, and 40g of enzyme activity of The liquid xylanase of 500000U / ml is mixed and stirred evenly to obtain a yellow-brown uniform liquid, which is the biological enzyme preparation for improving the paper strength of alkaline hydrogen peroxide mechanical pulp of the present invention.

Embodiment 3

[0033] In a 250mL stainless steel container, add 34g of deionized water, 10g of polyoxyethylene stearate (40) ether, 5g of polyethylene glycol, 50g of liquid cellulase with an enzyme activity of 800U / ml, and 1g of liquid cellulase with an enzyme activity of 500,000U / ml. ml of liquid xylanase, mixed and stirred evenly to obtain a yellow-brown uniform liquid, which is the biological enzyme preparation for improving the paper strength of alkaline hydrogen peroxide mechanical pulp of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com