A liquid aluminum alloy electromagnetic conveying equipment

A technology of conveying equipment and aluminum alloy, which is applied in the direction of sending molten metal into the mold, metal processing equipment, casting equipment, etc., which can solve the problem of affecting the automation level of casting production, affecting the quality of aluminum alloy castings, and deteriorating the casting production environment, etc. problems, to achieve the effect of improving the level of production automation and material utilization, realizing clean and safe production, and improving the level of production automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

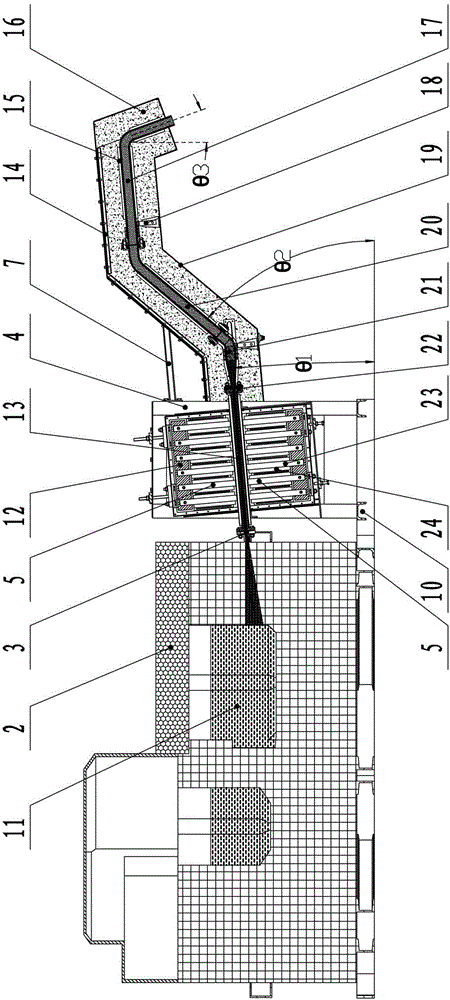

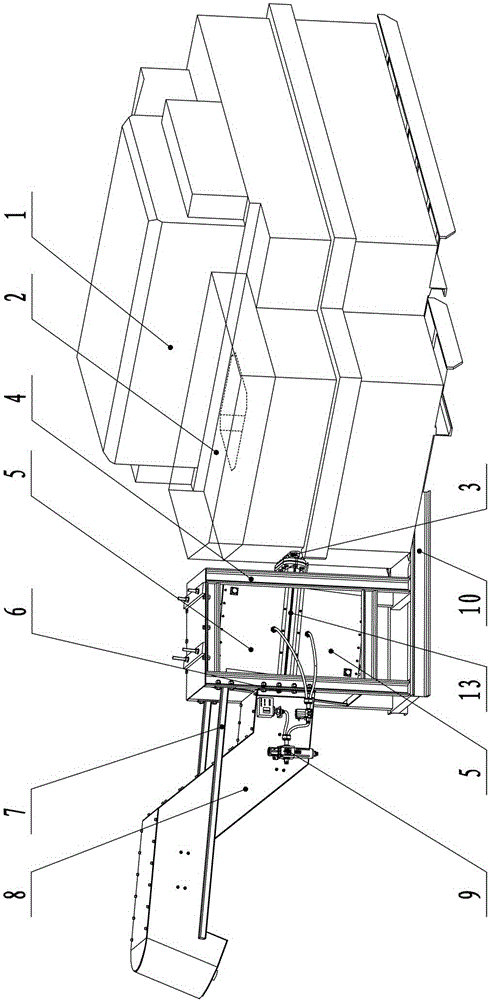

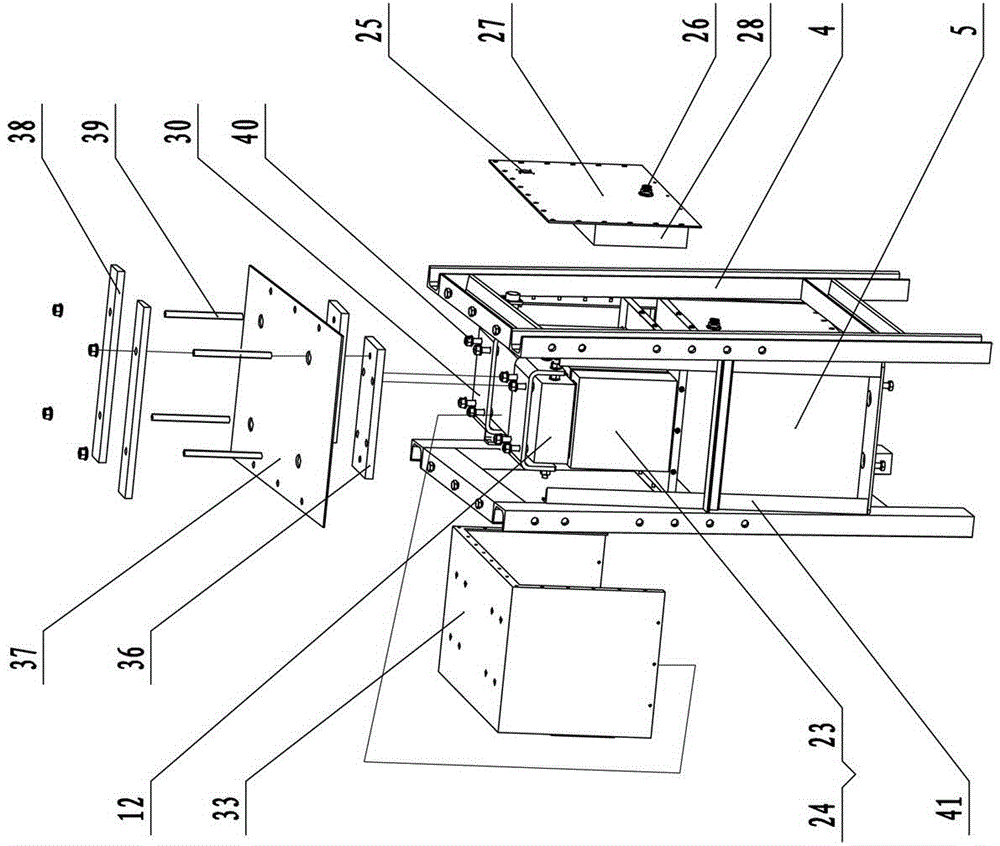

[0023] Such as figure 1 , 2As shown, the present invention includes an aluminum alloy liquid holding furnace 1, a flat pump ditch 13, an electromagnetic pump body 5 and its air cooling system 9, an electromagnetic pump body support 4 and a delivery pipeline 8, wherein: the holding furnace 1 adopts a holding furnace cover 2 Sealing is carried out, and a furnace side opening 3 is provided at a height of one third of the side wall of the holding furnace 1 from the bottom of the furnace cavity. The extension base 10 of the holding furnace is extended in 3 directions. Two separate electromagnetic pump bodies 5 are symmetrically arranged directly above and directly below the flat pump groove 13 . The electromagnetic pump body 5 is placed on the electromagnetic pump body support 4 with an adjustable magnetic gap, and is cooled by an air cooling system 9 . The electromagnetic pump body bracket 4 is fixed on the extension base 10 of the holding furnace. The other end of the flat pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com