Phosphorus loaded particles and methods for their preparation and use

A particle and red phosphorus technology, applied in the field of phosphorus-loaded particles and its preparation and use, can solve the problems of limiting polymer films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

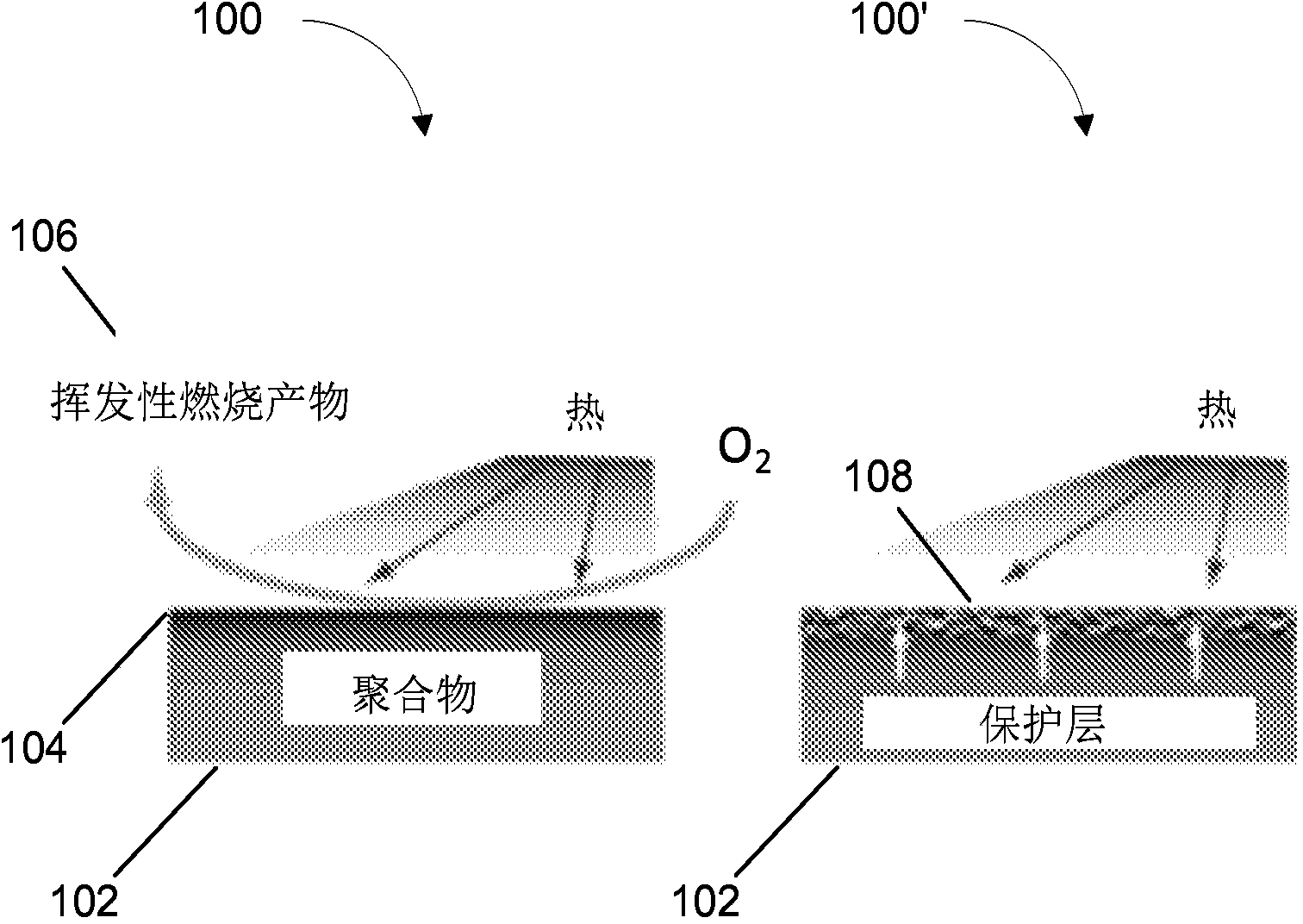

Problems solved by technology

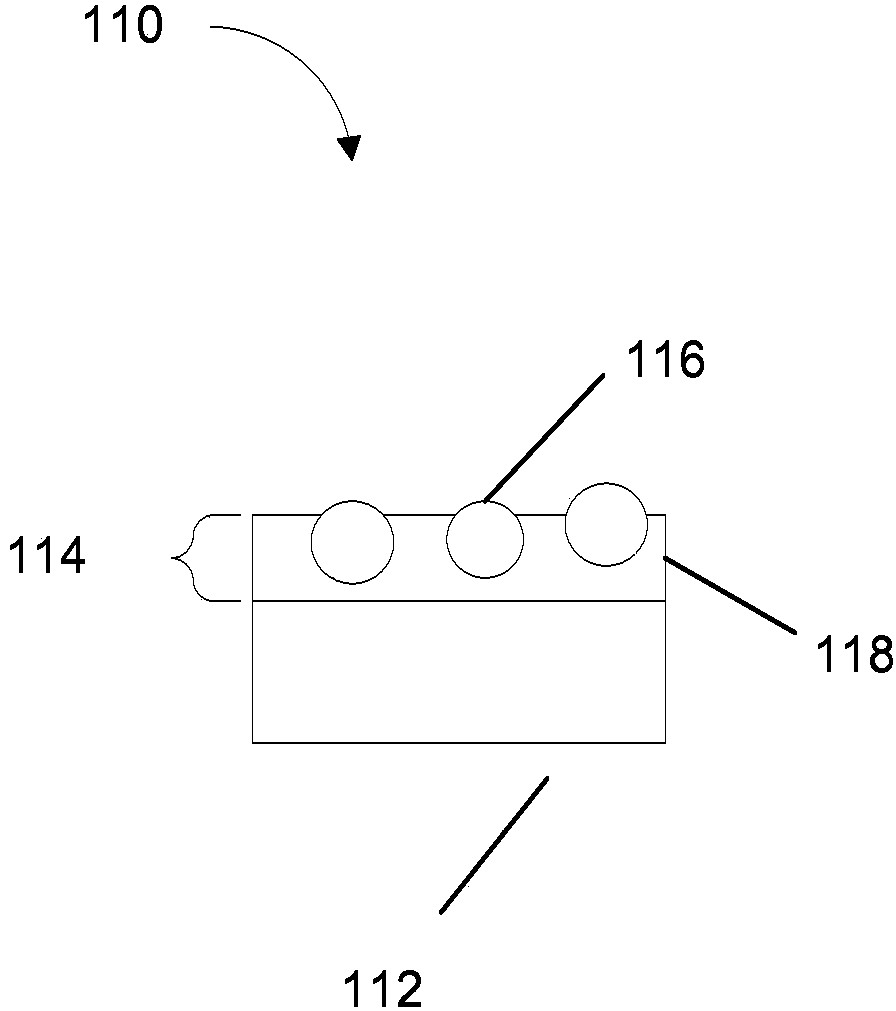

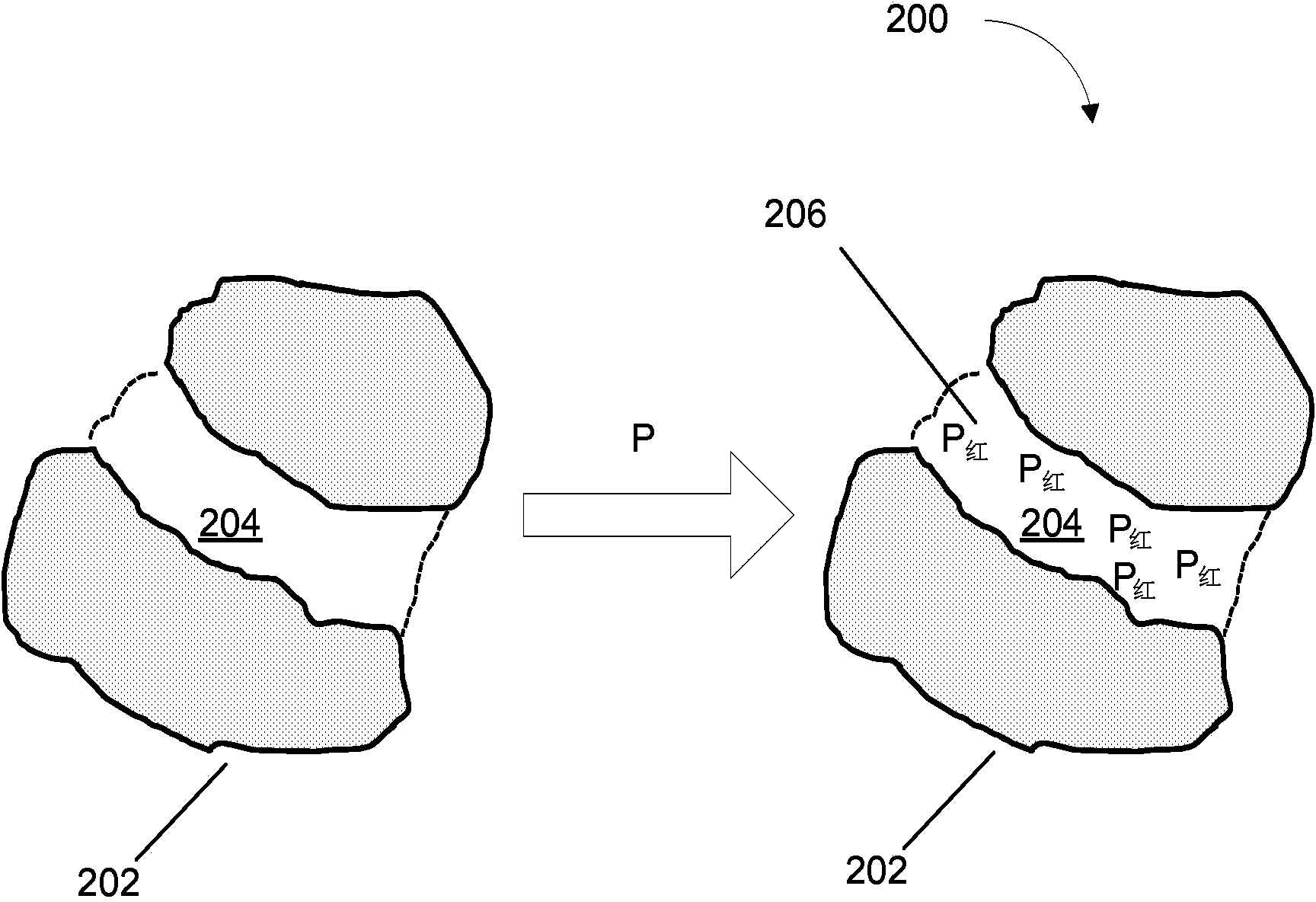

Method used

Image

Examples

Embodiment 1A

[0115] Example 1A: Preparation of exemplary non-combustible silica particles containing nanoscale pores: silica gel with the following characteristics can be obtained: particle size of about 35 microns to 75 microns (220 mesh to 440 mesh); nanopore diameter, about 60 Angstroms; nanopore volume, about 0.8 cm3 / g; surface area, about 50 m2 / g (Sigma-Aldrich, St. Louis, MO). The silica gel can be heated to 200° C. for 10 minutes in a rotary kiln to remove adsorbed water and allowed to cool to produce dry silica gel for use in the following examples.

Embodiment 1B

[0116] Example 1B: Preparation of exemplary non-combustible alumina particles comprising nanoscale porosity: alumina with the following characteristics can be obtained: particle size of about 50 microns to 75 microns (220 mesh to 290 mesh); surface area, about 200 square meters m / g (Sigma-Aldrich, St. Louis, MO). Alumina can be heated to 200° C. for 10 minutes in a rotary kiln to remove adsorbed water and allowed to cool to produce dry alumina for use in the following examples.

Embodiment 1

[0117] Example 1C: Adsorption of white phosphorus and conversion to red phosphorus in silica: 1 gram portion of dry silica gel can be combined with 1 gram of white phosphorus in a ceramic crucible and can be heated to 50°C. The silica gel and the obtained molten white phosphorus can be stirred together with a ceramic rod, and the mixture can be heated to 300° C. for 1 hour. The mixture can be cooled to room temperature, stirred with 25 mL of carbon disulfide at about 45°C for about 10 minutes, filtered, and washed with 3 x 20 mL of boiling carbon disulfide. The mixture can be removed from the filter and the remaining solvent removed under vacuum to obtain a dry powder which can then be passed through a 220 mesh screen to remove any large unadsorbed red phosphorus particles. The result was 1.9 g of dry silica flame retardant composition powder. The silica flame retardant composition can be analyzed and can be found to have the following characteristics: weight percent red phos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com