A method for extracting capsaicin and capsanthin from capsicum oleoresin

A technology of capsicum oleoresin and capsanthin, applied in chemical instruments and methods, natural dyes, azo dyes, etc., can solve problems such as environmental pollution, high labor intensity, incomplete extraction, etc., to eliminate environmental pollution and improve labor efficiency. Efficiency, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

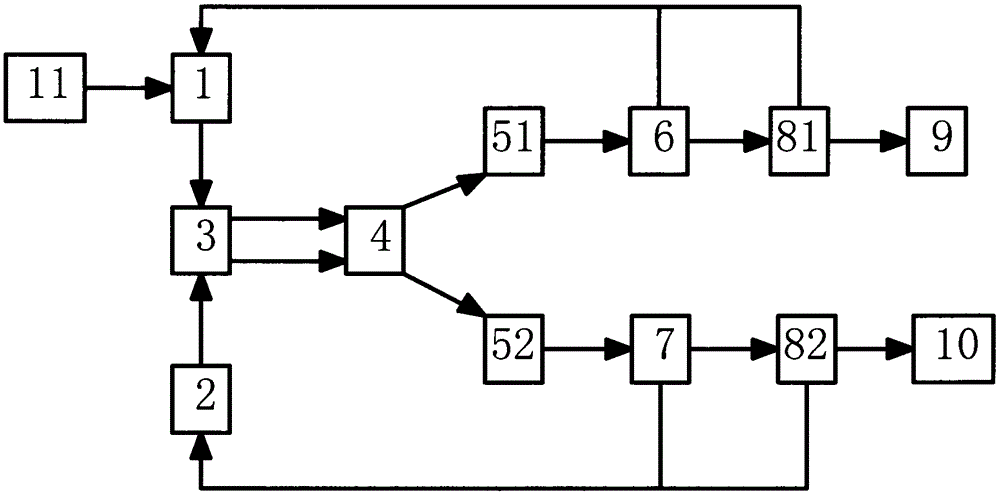

[0013] The present invention is described in further detail now in conjunction with accompanying drawing. Accompanying drawing is a simplified process flow chart, only schematically illustrates the basic process flow of the present invention.

[0014] Specific implementation one: please refer to figure 1 , a method for extracting capsaicin and capsanthin from capsicum oleoresin, the steps comprising:

[0015] (1), capsicum oleoresin 11 is made into preliminary dilution solution with diluent n-hexane in batching tank-1, wherein the volume ratio of capsicum oleoresin and diluent n-hexane is 1: 5;

[0016] (2), adding extractant methanol aqueous solution in batching tank two 2, the initial dilution solution prepared in step 1 and extractant methanol aqueous solution are transported in the cooler 3 according to the volume ratio 1:5;

[0017] (3), control the temperature of the cooling solution coming out of the cooling machine 3 between 25°C, send the cooling solution coming out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com