Patents

Literature

31results about How to "Guaranteed degradation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antibacterial argentum-carried hydroxylapatite/carbon nanotube composite artificial bone and preparation thereof

The invention discloses an antibacterial argentum-carried hydroxylapatite / carbon nanotube composite artificial bone and a preparation method thereof. Hydroxylapatite / carbon nanotube composite powder prepared by an in situ synthesis method is used as a carrier, and argentum-carried hydroxylapatite / carbon nanotube composite powder is obtained through ion exchange and ion adsorption; and the argentum-carried hydroxylapatite / carbon nanotube composite powder is used as a raw material, and the antibacterial argentum-carried hydroxylapatite / carbon nanotube composite artificial bone is prepared by a hot pressed sintering method. The artificial bone obtained by the method has obvious antibacterial effect, and not only maintains stronger mechanical property and good biological performance of the hydroxylapatite / carbon nanotube composite artificial bone, but also can treat and prevent infection so as to avoid multiple surgeries.

Owner:SHANDONG UNIV

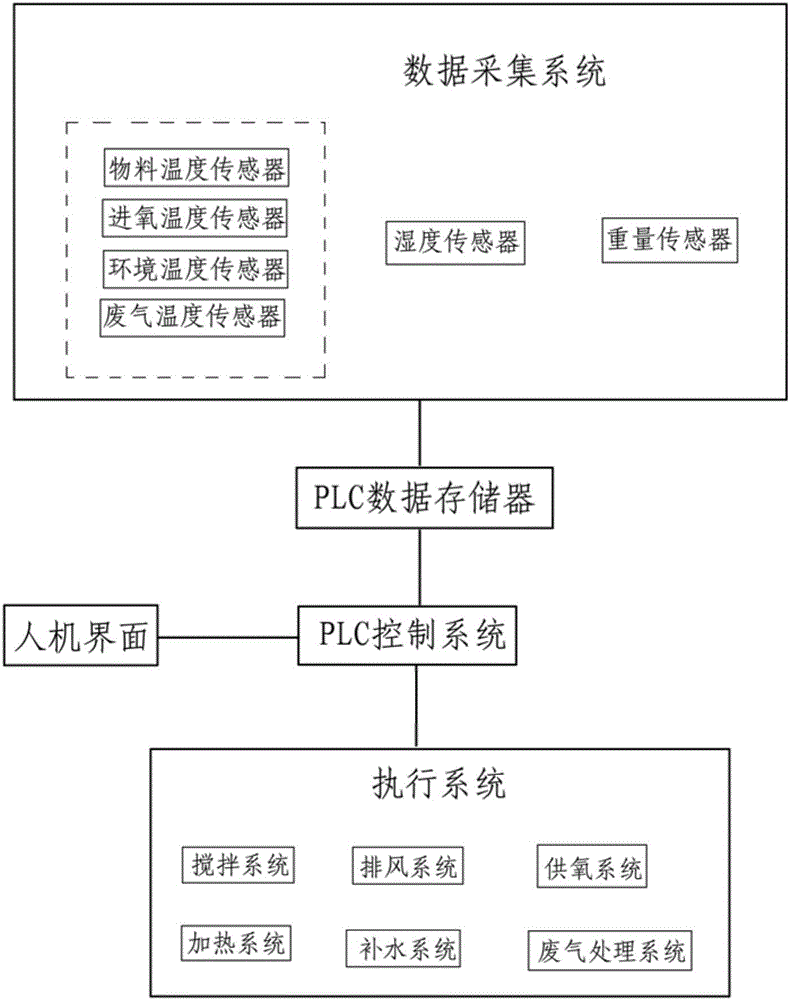

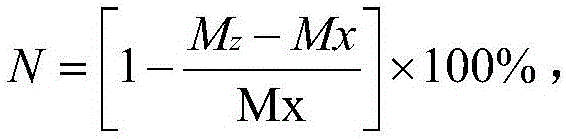

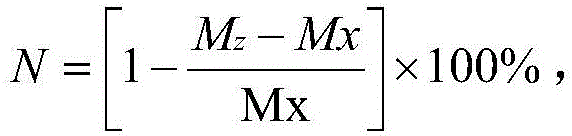

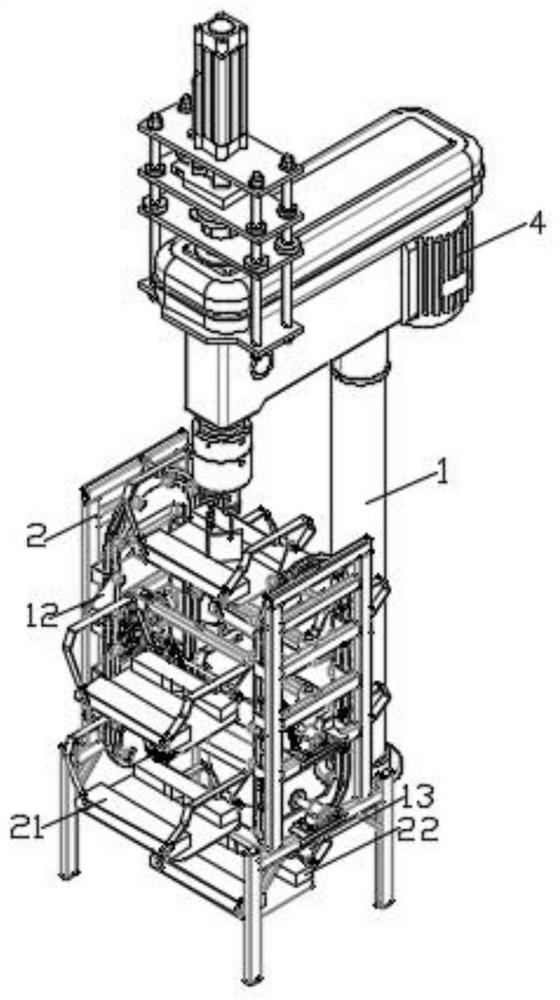

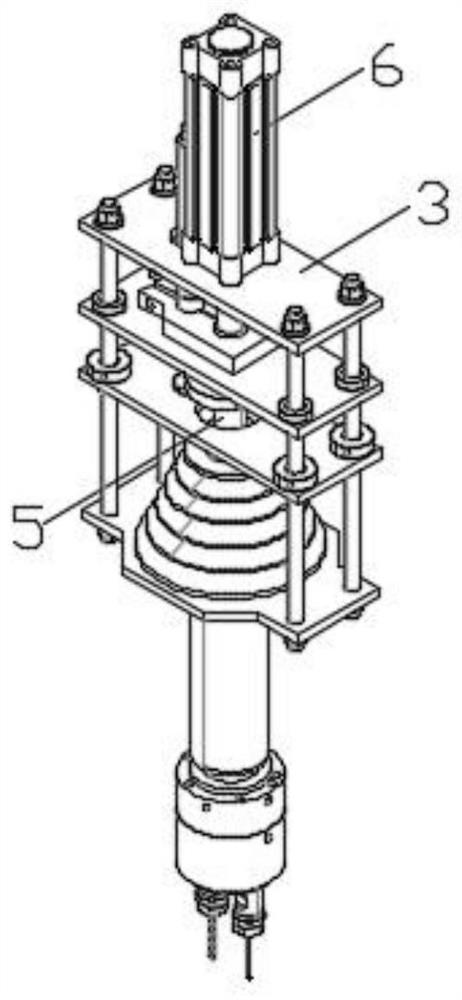

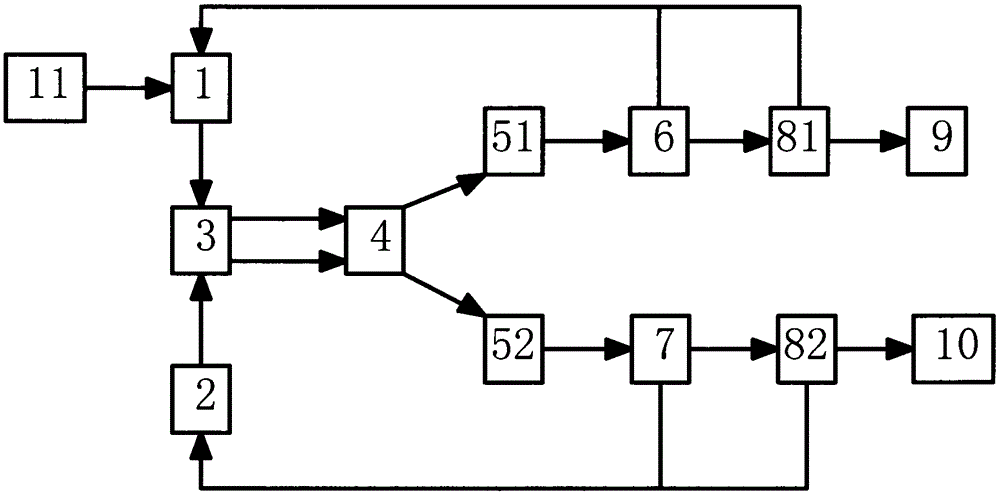

Intelligent control method and system for microbial decomposition process of organic matters

InactiveCN106431540AIncrease temperatureEasy to breedBio-organic fraction processingFertiliser treatment controlWeight changeDecomposition

The invention relates to an intelligent control method and system for a microbial decomposition process of organic matters. The invention aims to provide the intelligent control method and the intelligent control system for the microbial decomposition process of the organic matters; the temperature, humidity and weight changes of a material during microbial decomposition can be fully utilized, the temperature, humidity and oxygen supply quantity in the decomposition process can be intelligently controlled, and the decomposition efficiency of the organic matters is improved. According to the method, through acquisition of the temperature data, weight data and humidity data in the process of microbial decomposition of the organic matters, and with combination of predetermined ideal state temperature-time change data, ideal state humidity-time change data and ideal state decomposition rate-time change data of microbial flora in the organic matter decomposition process, the temperature, humidity, oxygen supply and decomposition rate in the organic matter decomposition process are adjusted.

Owner:SHANGHAI YIKE ENVIRONMENT TECH CO LTD

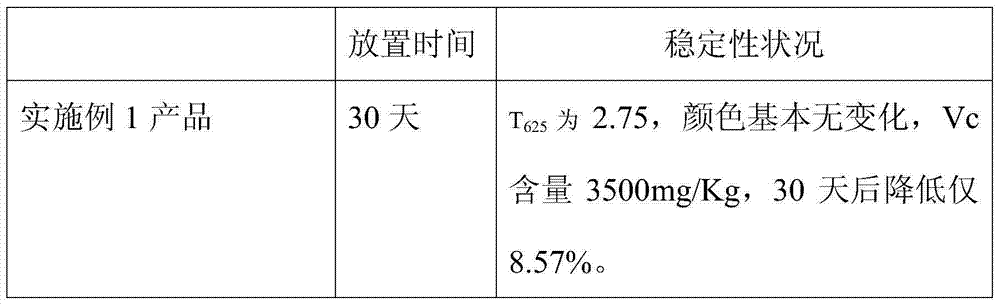

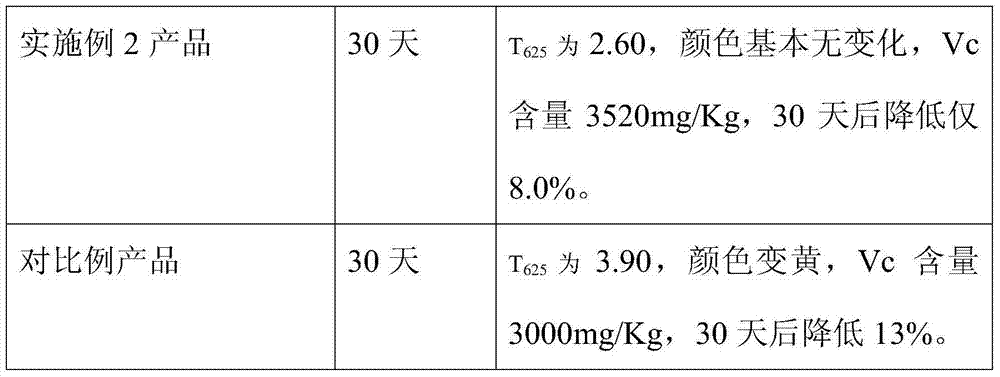

Not-concentrated freshly squeezed compound fresh jujube juice and processing method thereof

ActiveCN104287006AEnhance fragranceIncrease moisture contentNatural extract food ingredientsFood preparationNutrientKiwi fruit

The invention discloses non-concentrated freshly squeezed compound fresh jujube juice and a processing method thereof, and the compound fresh jujube juice comprises the following raw materials by weight: 45-60 parts of fresh jujube, 45-60 parts of snow pear, 7-10 parts of kiwi fruit and 1-5 parts of cucumber. The compound fresh jujube juice is prepared as follows: a variety of finely selected ripe fresh fruits are pretreated and then frozen for more than 24h, then pulped and squeezed at 0 DEG C, and then processed by vacuum degassing, aseptic filling, and ultra high pressure sterilization. The compound fresh jujube juice prepared under the cold processing conditions is not subjected to heat treatment to prevent damage of nutrient substances in fruit and fresh jujube color degradation, the prepared compound fresh jujube juice product is green and yellow in color, uniform in quality, refreshing and fragrant, and is non-concentrated freshly squeezed nutritional fresh jujube juice meeting modern consumption demands.

Owner:NORTHWEST A & F UNIV

Antibiotic silver-carrying modified artificial coral bone and its prepn process

The antibiotic silver-carrying modified artificial coral bone consists of modified artificial coral bone with controllable degradation speed as carrier and adsorbed silver ion particle. The modified artificial coral bone consists of calcium carbonate in 30-70 wt% and hydroxyapatite. The preparation process of the antibiotic silver-carrying modified artificial coral bone includes the following steps: 1. preparing modified artificial coral bone; 2. soaking the artificial coral bone in silver nitrate solution, heliophobic vacuum low temperature freeze drying, adding sodium chloride solution to form silver chloride precipitate on the surface of the artificial bone and heliophobic vacuum low temperature freeze drying; and 3. distilled water dialysis to prepare antibiotic silver-carrying modified artificial coral bone.

Owner:GUANGZHOU MAIBANG BIOLOGICAL SCI TECH

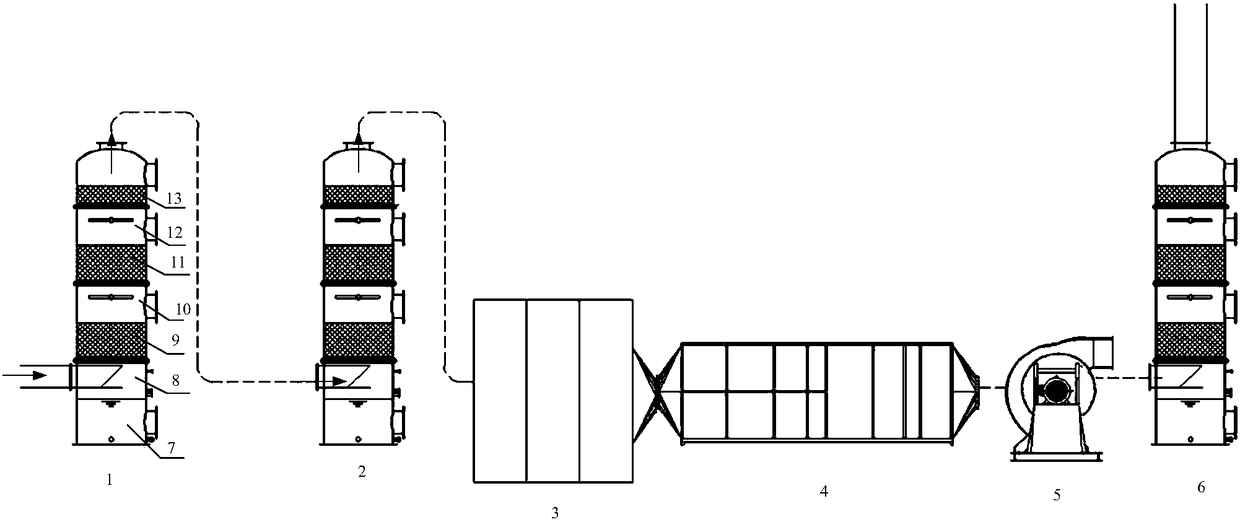

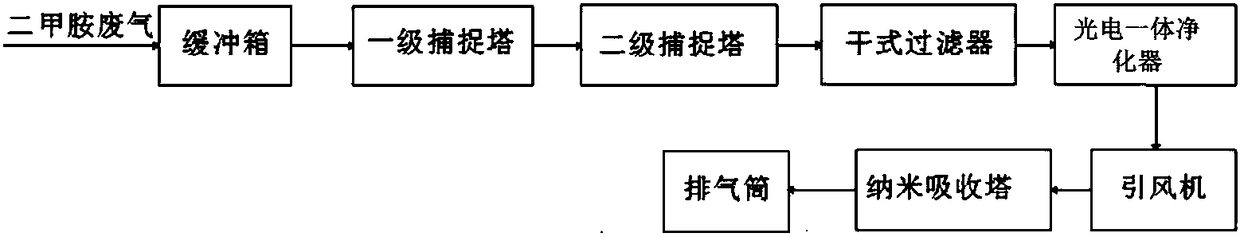

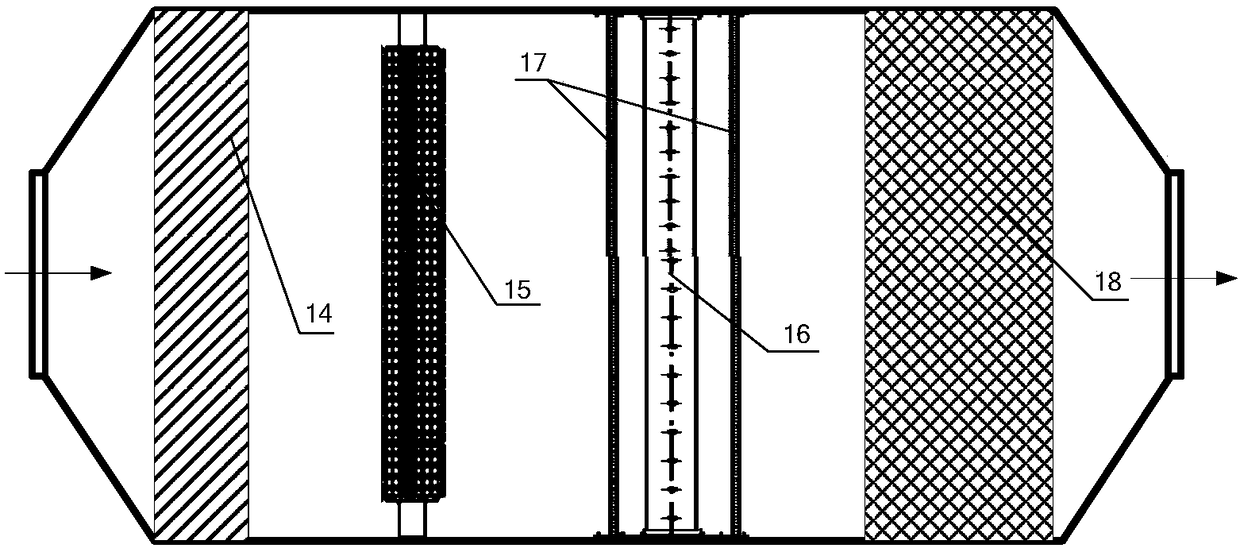

Dimethylamine waste gas treatment device and process in synthetic leather industry

PendingCN108554172AImprove discharge efficiencyGuaranteed degradationCombination devicesGas treatmentDischarge efficiencyLeather industry

The invention discloses a dimethylamine waste gas treatment device and process in synthetic leather industry. The dimethylamine waste gas treatment device comprises a primary capture tower, a secondary capture tower, a dry filter, a photoelectric integral purifier and a nanometer absorption tower, wherein an air outlet of the primary capture tower is connected with an air inlet of the secondary capture tower through a pipeline; an air outlet of the secondary capture tower is connected with an air inlet of the dry filter through a pipeline; an air outlet of the dry filter is connected with an air inlet of the photoelectric integral purifier; an air outlet of the photoelectric integral purifier is connected with an air inlet of the nanometer absorption tower through a pipeline. A discharginghigh-voltage electrode is arranged in a plasma reaction section; the discharging high-voltage electrode is of a stainless steel mace structure. Compared with the prior art with the defects that the pretreatment efficiency is low, so that spark discharge is generated in the plasma discharging process, and meanwhile, the oil mist influences the discharging process efficiency, the dimethylamine waste gas treatment device and process have the advantages that after the two-stage capture towers are added, the plasma discharging efficiency is improved; sufficient high-energy active substances are generated; further, the dimethylamine degradation is ensured.

Owner:HANGZHOU DIANZI UNIV +1

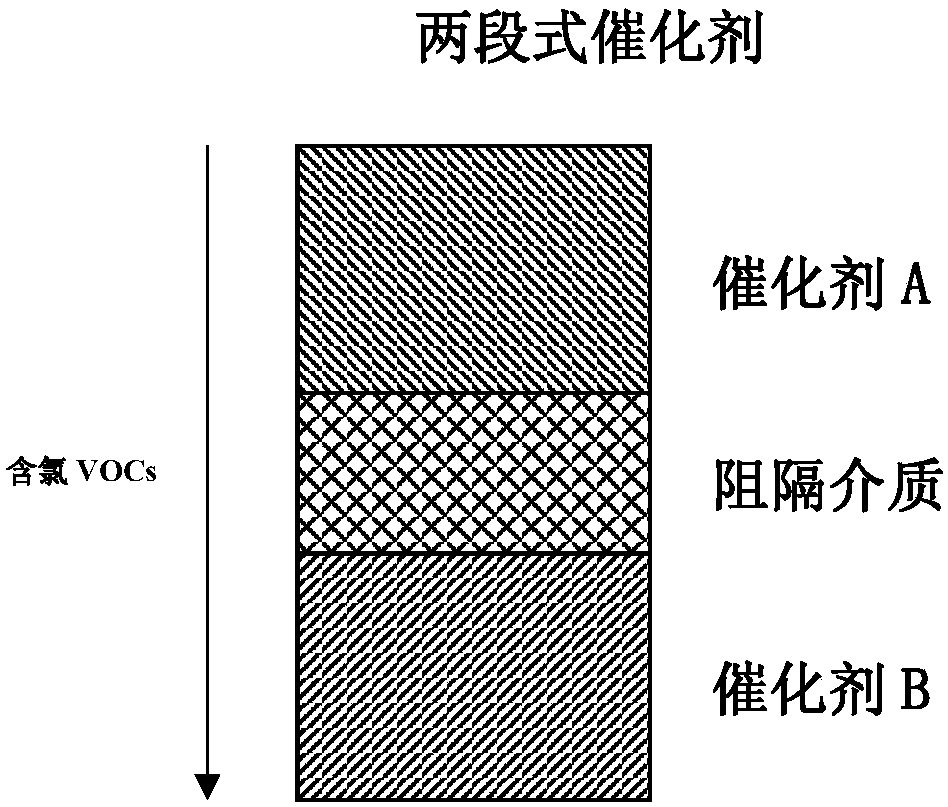

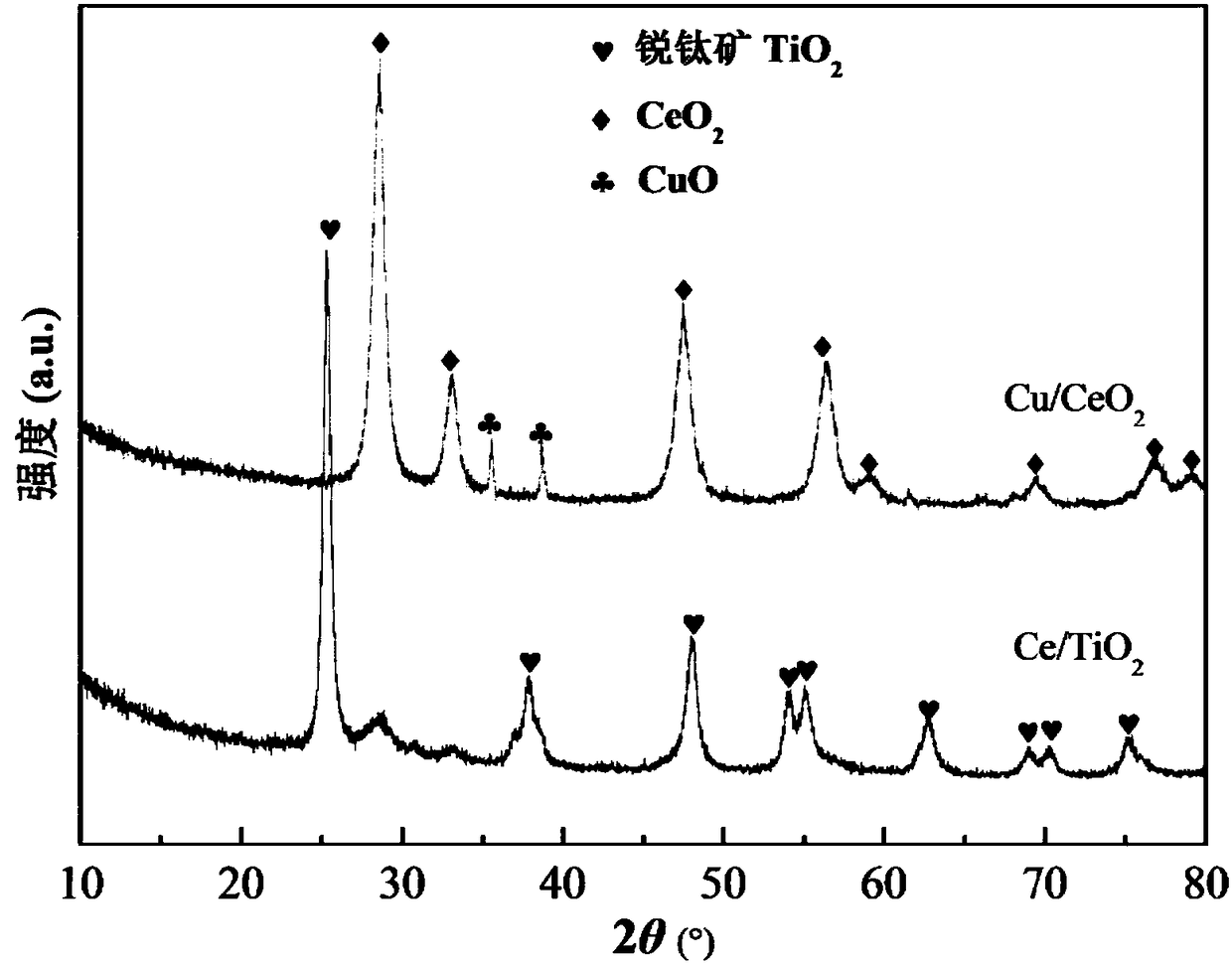

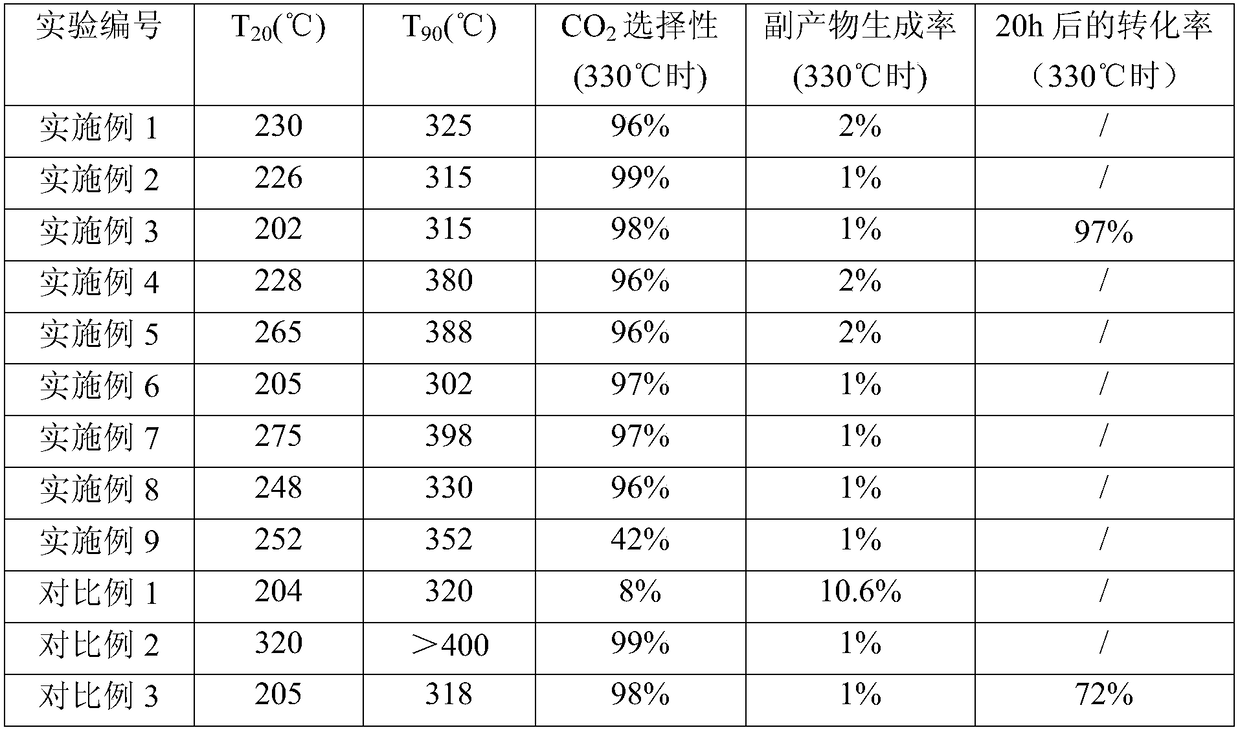

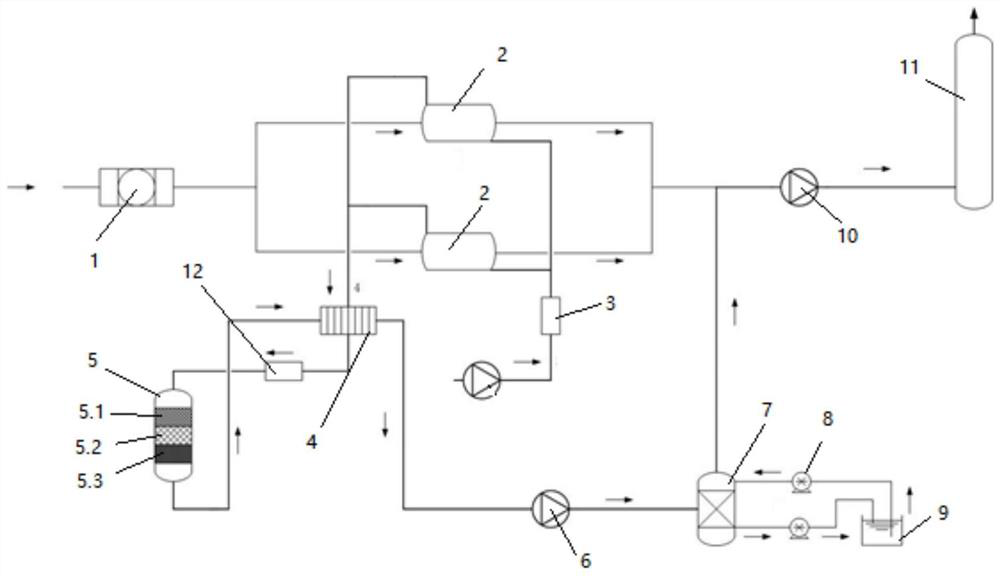

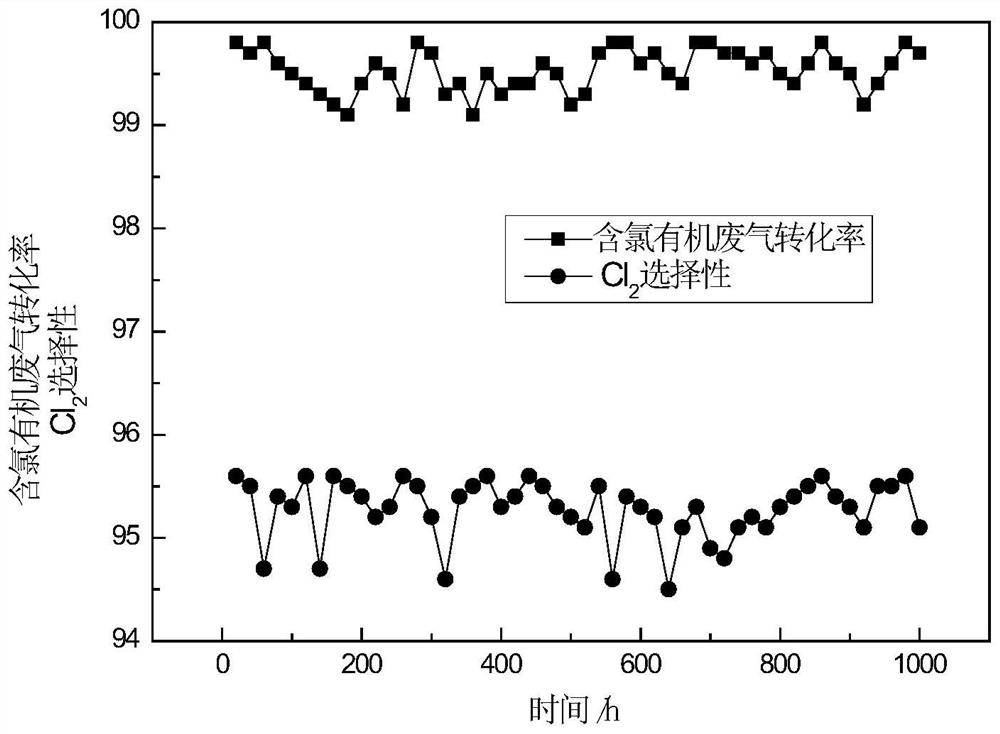

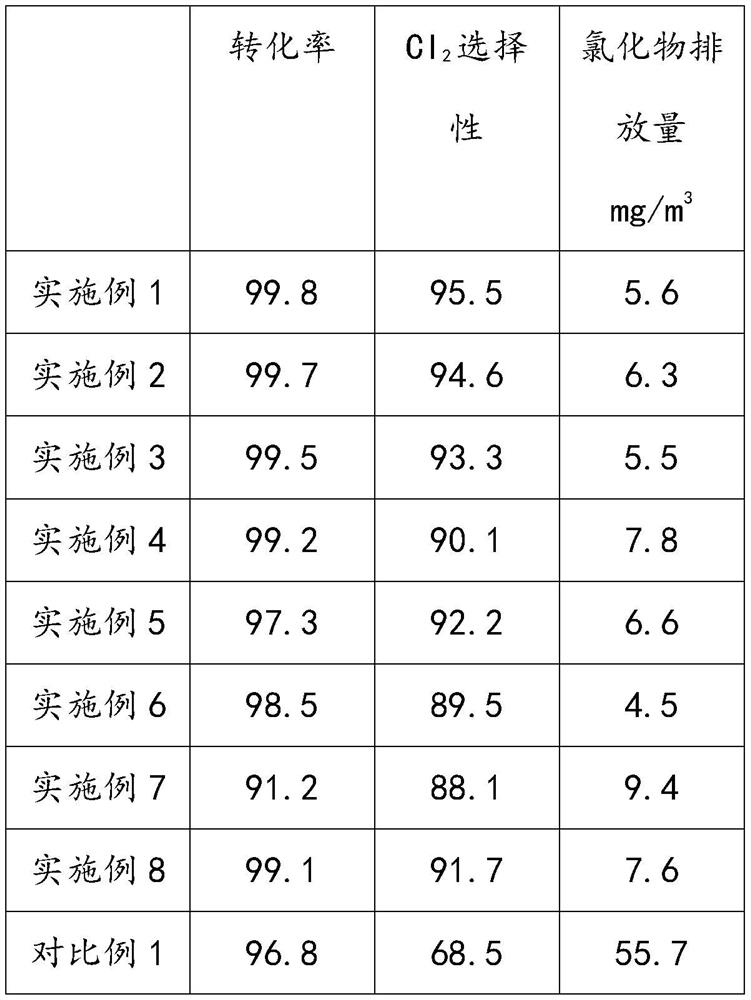

Two-stage catalyst for catalytic degradation of chlorine-containing volatile organic chemicals (VOCs) as well as preparation method and application of two-stage catalyst

InactiveCN108126685AGuaranteed complete oxidationDegradation GuaranteeGas treatmentCatalyst protectionGlass fiberChemical compound

The invention discloses a two-stage catalyst for catalytic degradation of chlorine-containing volatile organic chemicals (VOCs) as well as a preparation method and application of the two-stage catalyst. The two-stage catalyst is prepared from a catalyst A, a catalyst B and a barrier medium, wherein the catalyst A and the catalyst B are set in two stages, and the two stages of catalysts are isolated from each other by means of the barrier medium; the active components of the catalyst A are at least one of compounds of Ce, Cr, V, Fe and Ni, and a carrier of the catalyst A is an acidic oxide; theactive components of the catalyst B are least one of compounds of Cu, and a carrier of the catalyst B is CeO2; the barrier medium is at least one of SiO2, Al2O3, quartz sand, quartz wool and glass fibers. The two-stage catalyst can well solve the problems of deep oxidation and catalyst chlorine poisoning.

Owner:ZHEJIANG UNIV

Easily degradable plastic bag

The invention provides an easily degradable plastic bag. The easily degradable plastic bag comprises the following components in percentage by weight: 40-60% of film-grade polyethylene, 20-40% of film-grade polylactic acid, 1-15% of a plasticizer and 2-8% of glass fiber. The easily degradable plastic bag is produced by a plastic film blowing machine and has the advantages that the production process is simple, the plastic bag can be automatically degraded when the temperature of the environment is higher than 55 DEG C, and the abandoned polylactic acid films can be degraded in the abandoned environment.

Owner:TIANCHANG EARTHQUAKE OFFICE

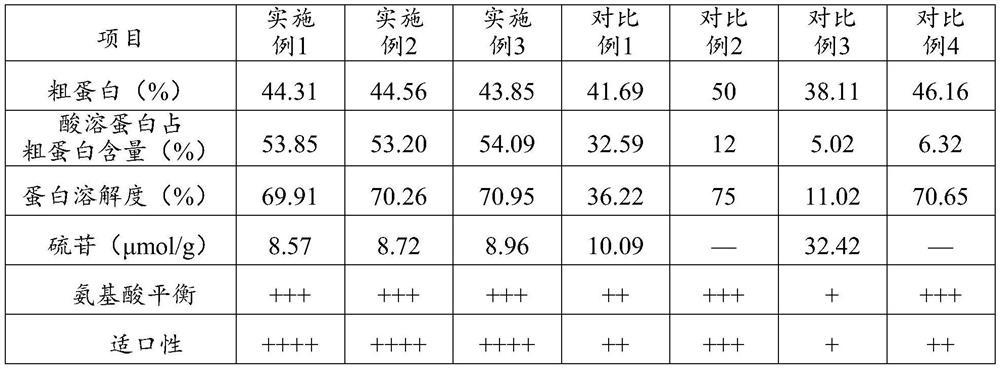

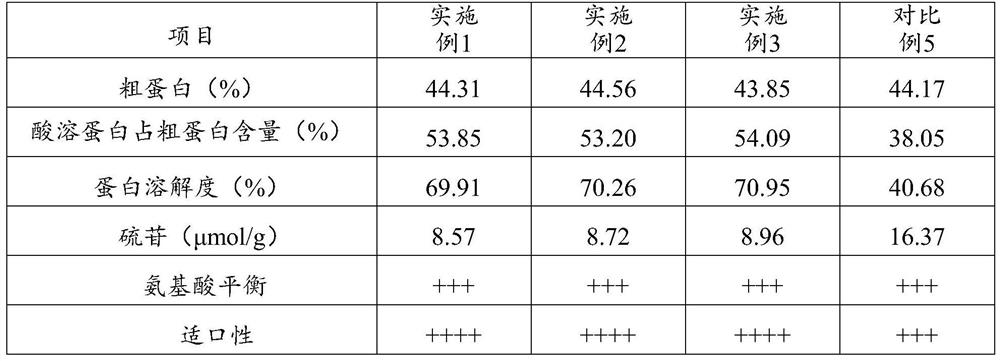

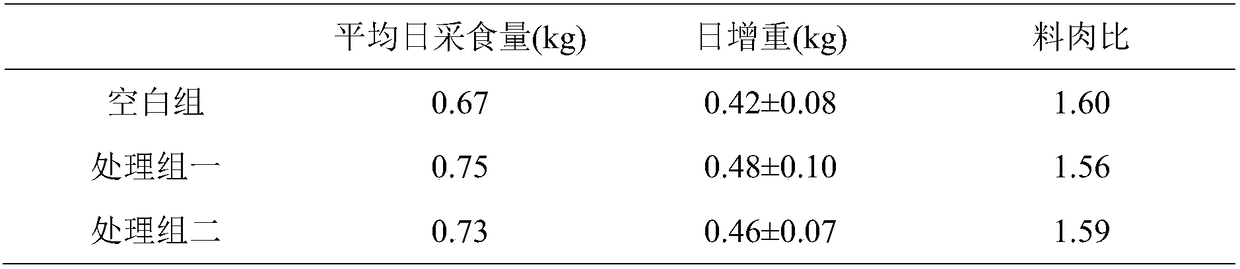

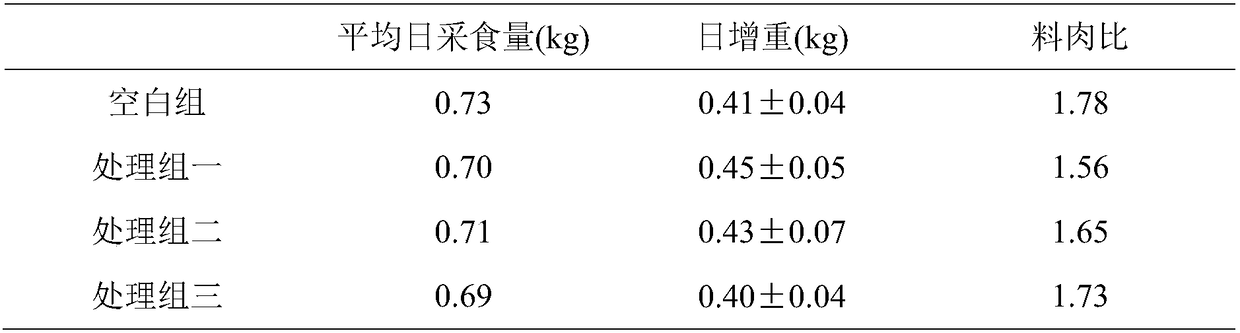

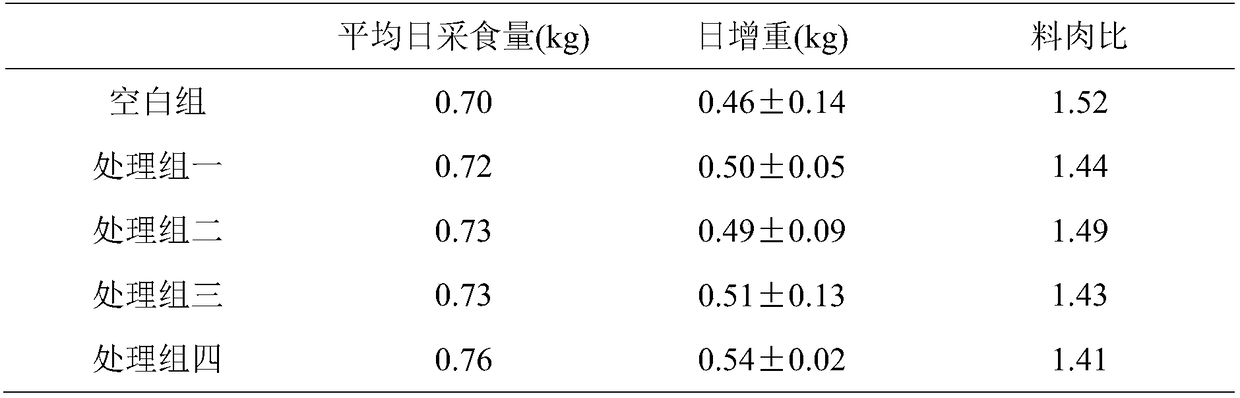

Preparation method of fermented protein feed and fermented protein feed

PendingCN111903835AImprove and adjust the problem of species imbalanceInhibition of growth and reproductionFood processingAnimal feeding stuffBiotechnologyNutrition

The invention provides a preparation method of a fermented protein feed and the fermented protein feed, and belongs to the technical field of biological fermented feeds. The preparation method comprises the following steps: 1) mixing a protein raw material with water, Tween 80 and a peroxyacetic acid solution to obtain a mixed material; 2) inoculating the mixed material obtained in the step 1) with aspergillus oryzae, and performing solid-state aerobic fermentation to obtain a fermented material; and 3) mixing the fermented material obtained in the step 2) with an enterococcus faecium culturesolution and water, and performing anaerobic fermentation and enzymolysis to obtain the fermented protein feed. Experimental results show that the preparation method of the fermented protein feed hasthe effects of reducing the contents of toxic, harmful and anti-nutritional ingredients in protein raw materials, increasing the content of acid-soluble protein, increasing the solubility of protein,improving and regulating amino acid balance and improving the palatability of the feed, so that the nutritional requirements for production of complete formula feeds or breeding of animals can be better met.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

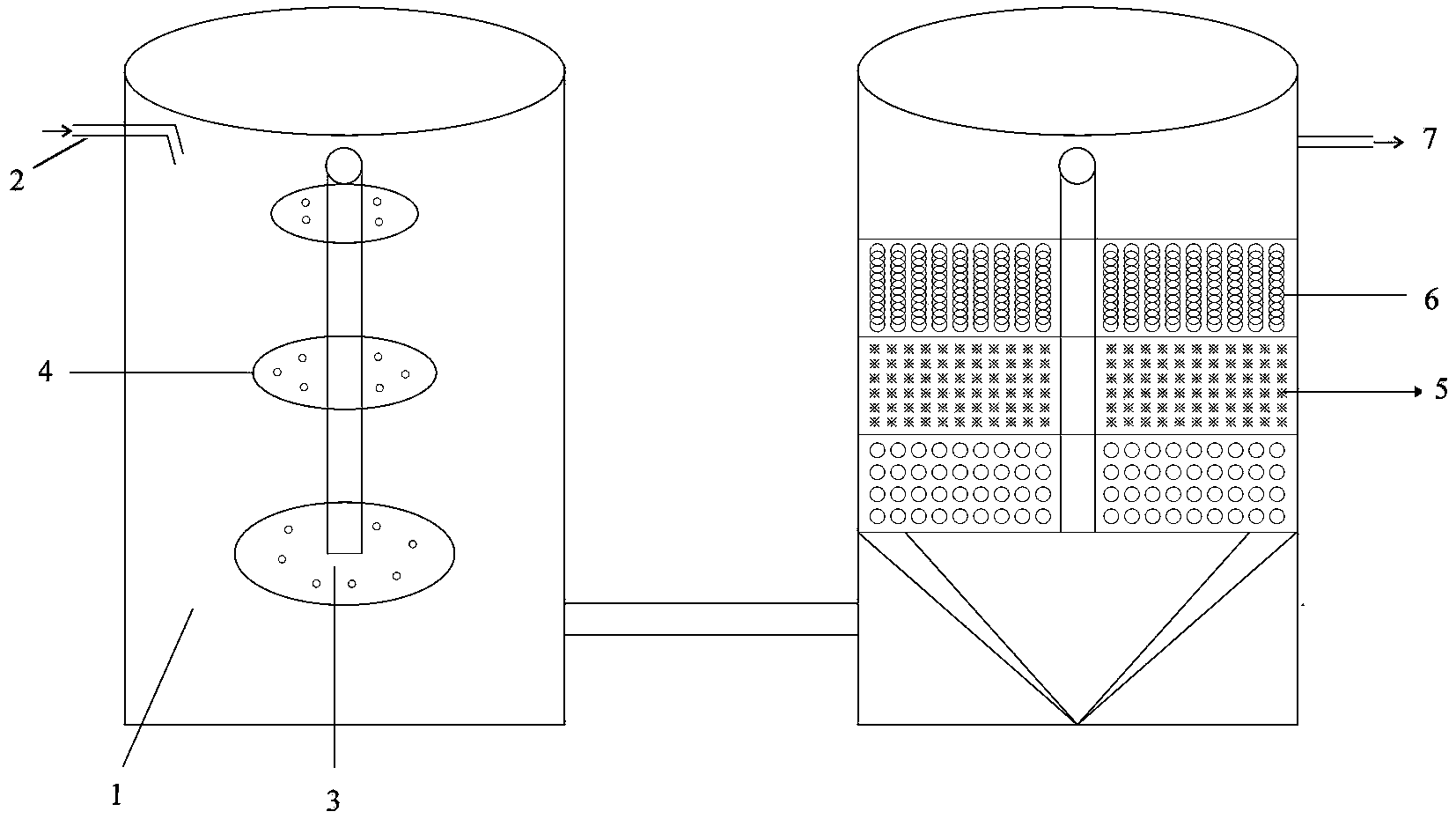

Domestic sewage filtering device

InactiveCN104163542AReduce impactLiquid flow is stableMultistage water/sewage treatmentEngineeringFilter material

The invention discloses a domestic sewage filter device, which comprises two parts of a separation device and a filtering device; the separation device is a cylinder, an upper side face of the cylinder is provided with a water inlet, a support column is arranged in the middle of the cylinder, the support column is provided with movable separation disintegrators, a lower side face of the cylinder is provided with a water outlet; the filtering device is a cylinder, the lower side face of the cylinder is provided with a water inlet, the water inlet of the cylinder of the filtering device is connected with the water outlet of the cylinder of the separation device, an upper side face of the cylinder of the separation device is provided with a water outlet, multi layers of filter materials are arranged from bottom to top in the cylinder of the separation device, the lower filter material is arranged on a filter plate, the filter plate is supported by a column or other substances, and an exhaust pipe is arranged in the middle of the filter materials. The domestic sewage filter device adopts the technical scheme, compared with the prior art, the domestic sewage filter device has the advantages of full sewage degradation, fast purification, simple structure, and up-to-standard sewage discharge.

Owner:苗育卓 +1

Production process of environment-friendly degradable plastic film

The invention discloses a production process of an environment-friendly degradable plastic film. The production process of the plastic film comprises the following steps of 1, preparing and screening raw materials such as polyethylene plastic particles, polylactic acid plastic particles and starch plastic particles, 2, melting and mixing the raw materials, 3, extruding the raw materials mixed in the step 2 through a casting machine, 4, cooling the film extruded in the step 3, 5, flattening the cooled film through a flattening device, 6, spraying, washing and drying the flattened film, and 7, slitting and rolling the dried film. According to the production process of the environment-friendly degradable plastic film, the production efficiency can be guaranteed, full mixing of raw materials is guaranteed, and what can be guaranteed is that the plastic film is rapidly and fully degraded.

Owner:福建新达人塑胶制品有限公司

Environmentally-friendly degradable plastic and preparation method thereof

The invention provides an environmentally-friendly degradable plastic and a preparation method thereof, and relates to the technical field of plastic processing. The environmentally-friendly degradable plastic is prepared from, by weight, 40-50 parts of polylactide, 12-14 parts of polybutylene succinate, 4-8 parts of polyvinyl chloride, 4-10 parts of plant fibers, 30-40 parts of grafted starch, 1-3 parts of calcium oxide, 1-3 parts of oligosaccharides, 1-1.6 parts of nano-silica, 1-2 parts of polyaluminum chloride, 0.6-1.6 parts of sodium citrate, 0.4-0.8 part of a dispersant, 0.2-0.5 part ofa crosslinking agent and 1-1.2 parts of a plasticizer. The preparation method overcomes the deficiencies of the prior art, adopts a combination of various biodegradable components to prepare the starch blended plastic in order to make the product effectively and completely degraded, and has the advantages of simple production process, convenience in production and low cost, and is suitable for promotion and production.

Owner:安徽新利清洁用品有限公司

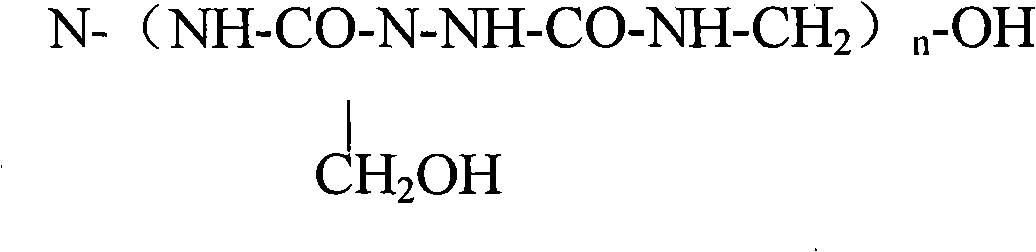

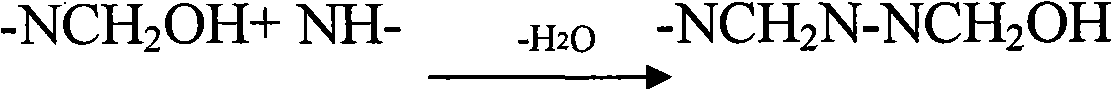

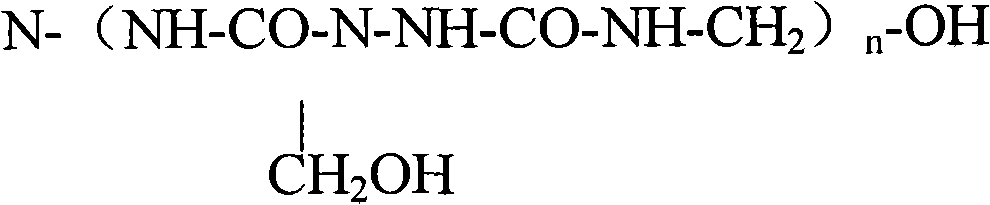

Manufacturing method of urban energy-saving and environmental-friendly cultivation medium

InactiveCN102101933AAvoid burning seedlingsIncrease matrix nutrientsCultivating equipmentsSoilless cultivationElastomerMethyl group

The invention relates to a manufacturing method of an urban energy-saving and environmental-friendly cultivation medium, which comprises the following implementation steps: in the first phase of an addition reaction, urea and formaldehyde are allowed to perform a hydroxymethylation reaction in a medium with a neutral or slightly alkaline pH of 7-8 to obtain monomethylol urea and dimethylol urea; further reaction is performed to obtain trimethylol urea and tetramethylol urea when the molar ratio of formaldehyde and urea (F / U) is higher; in the second phase of a polycondensation reaction, various methylol ureas are allowed to perform condensation in a weak acid condition with a pH of 4-6 to obtain a hydrophilic resin, wherein in the molecular structure, the hydroxymethyl group and the hydrogen connected to the nitrogen have a polycondensation capability; with the progress of the above reaction, the molecular weight increases gradually, and the molecular state becomes more complex, and even a network structure is formed, so the resin becomes an elastomer with a stereo configuration. The invention uses urea formaldehyde foam plastics as a novel plant cultivation medium to substitute soil, is environmental-friendly and can effectively save resources.

Owner:天津市津鸥化肥有限责任公司

Daily environment-friendly degradable plastic thin film

The invention relates to daily environment-friendly degradable plastic thin film. The daily environment-friendly degradable plastic thin film is prepared from, by weight percentage, 50-80% of thin-film-grade polyethylene and 20-50% of thin-film-grade polylactic acid. The polylactic acid is an ideal fully-degradable plastic, and the thin-film-grade polylactic acid and the thin-film-grade polyethylene can be blended to prepare the degradable plastic film with different degradation rates. The daily environment-friendly degradable plastic thin film can be produced by using a common plastic film blowing machine, during production, thin-film-grade polyethylene particles and the thin-film-grade polylactic acid can be uniformly mixed, and the degradable plastic thin film can be formed through blowing of the plastic film blowing machine. The components of the thin film are the polylactic acid and thin-film-grade polyethylene plastics, and since the polylactic acid can be automatically decomposed at the ambient temperature higher than 55 DEG C or under the function of rich oxygen and microorganisms, the degradation of the discarded polylactic acid thin film in the discarded environment can be ensured.

Owner:王翼

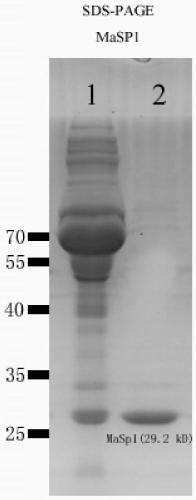

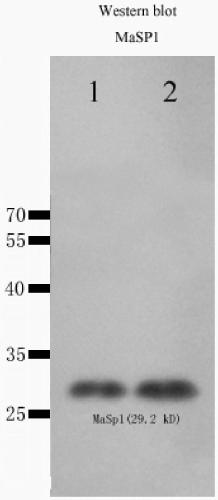

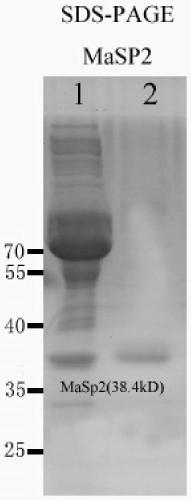

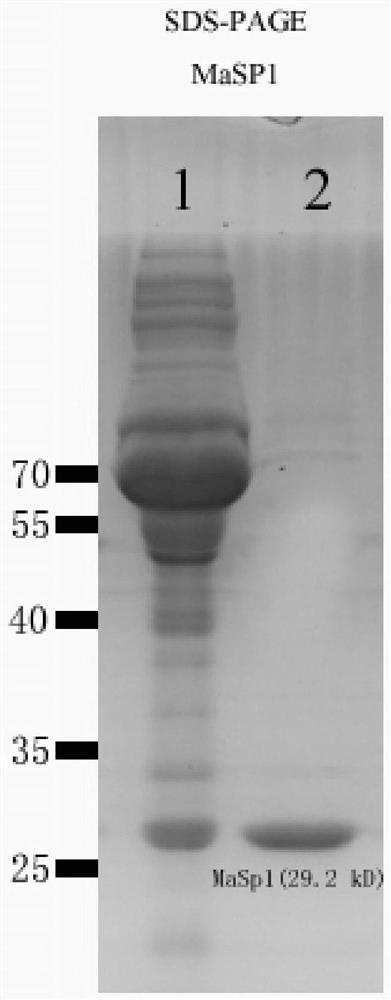

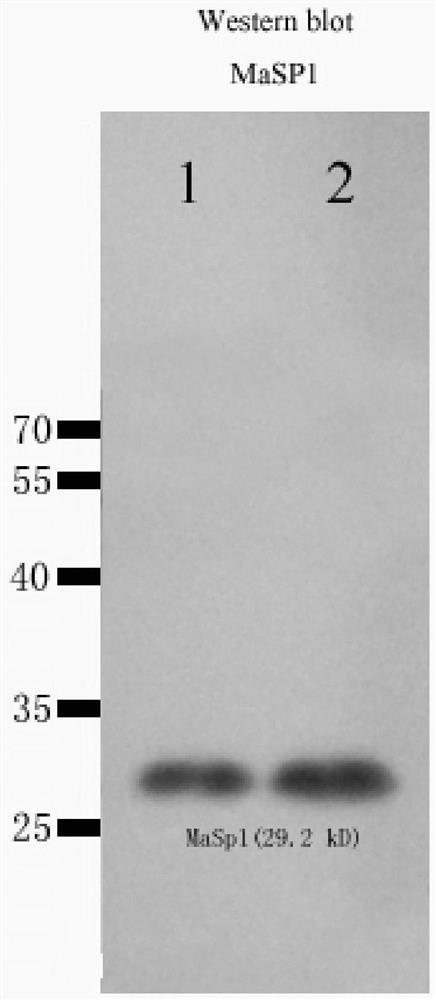

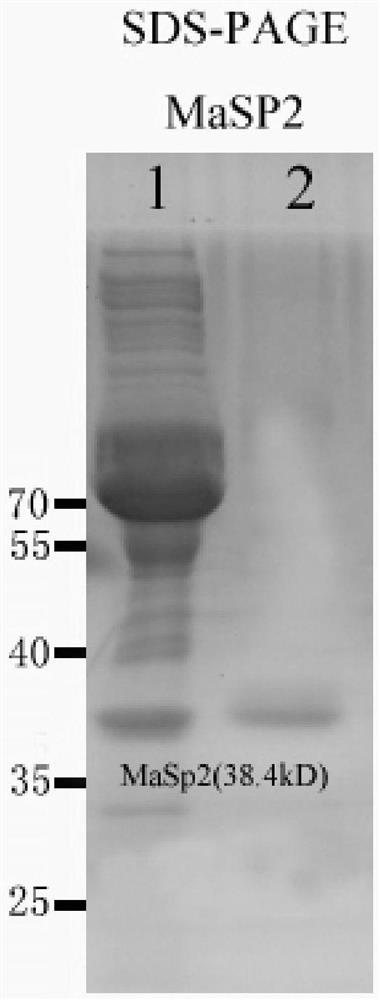

Recombinant spider silk protein and application thereof

ActiveCN110117328AWith controlled degradationWide range of usesMonocomponent protein artificial filamentOrganic non-cellulose fibresEnzyme digestionBiological materials

The invention provides a recombinant spider silk protein. The sequence structure comprises at least two spider silk protein structural domain monomers and at least one protease enzyme digestion site;each protease enzyme digestion site is positioned between every two adjacent spider silk protein structural domain monomers. By inserting each protease enzyme digestion site between every two adjacentspider silk protein domain monomers, when the recombinant spider silk protein is used in vitro, the recombinant spider silk protein can be combined with a tool enzyme to control the enzymolysis of the recombinant spider silk protein. Compared with existing spider silk proteins which need to be slowly degraded for a long time under the assistance of microorganisms, the recombinant spider silk protein has the advantage of controllable degradation; when the recombinant spider silk protein is used in the human body, since the protease enzyme digestion sites on the recombinant spider silk proteincan be enzymatically hydrolyzed by enzymes in the human body, a biological material prepared from the recombinant spider silk protein can be slowly degraded in the human body, so that the applicationvalue of the recombinant spider silk protein is increased, and the application is wider.

Owner:SUZHOU BAIYUAN GENT CO LTD

Complex enzyme capable of improving production properties of suckling piglets and application of complex enzyme

InactiveCN109393185AIncrease profitImprove digestibilityAccessory food factorsPectinaseNeutral protease

The invention relates to the field of feed additives, in particular to a complex enzyme capable of improving production properties of suckling piglets and an application of the complex enzyme. The complex enzyme comprises 60-80wt% of endogenous enzymes and 20-40wt% of non-starch polysaccharides enzymes, wherein the endogenous enzymes comprise low-temperature alpha-amylase, glucamylase, acid protease, neutral protease and alkali protease; and the non-starch polysaccharides enzymes comprise xylanase obtained through trichoderma reesei liquid fermentation, mannase obtained through aspergillus niger solid fermentation, beta-glucanase, cellulase and pectinase. The problem of low digestion and utilization rate of a feed, caused by imperfect digestive enzymes of the suckling piglets at the stagecan be effectively solved, and the raising cost can be saved.

Owner:北京盛拓达生物技术有限公司

Degradable plastic film

A degradable plastic film is composed of film-grade polyethylene and film-grade polylactic acid. The weight percentage of film-grade polyethylene is 50%-80%, and the weight percentage of film-grade polylactic acid is 20%-50%. Polylactic acid is an ideal fully degradable plastic, and film-grade polylactic acid and film-grade polyethylene can be blended to make degradable plastic films with different degradation rates. The invention can be produced by an ordinary plastic film blowing machine. During production, the film-grade polyethylene particles and film-grade polylactic acid can be evenly mixed, and the degradable plastic film can be blown by the plastic film blowing machine. The composition of the present invention has polylactic acid and film-grade polyethylene plastics, because polylactic acid will decompose automatically when the ambient temperature is higher than 55°C or under the action of oxygen-enriched and microorganisms, the discarded polylactic acid film will be in the discarded environment , can guarantee degradation.

Owner:TIANJIN KAIXUAN PLASTIC PROD

Polyoxymethylene monofilament for fishing as well as preparation method and application of polyformaldehyde monofilament

ActiveCN110129921AGood spinnability and comprehensive performanceNo broken wireMonocomponent synthetic polymer artificial filamentConjugated synthetic polymer artificial filamentsChemistryMelt spinning

The invention discloses a polyformaldehyde monofilament for fishing. The polyformaldehyde monofilament is prepared from the following components in parts by weight: 75-90 parts of polyformaldehyde, 0.5-3 parts of graphene, 7.5-17 parts of thermoplastic polyurethane, 0.5-3 parts of an antioxidant, 0.5-1 part of a formaldehyde absorbent and 0. 5-1 part of a lubricant. According to the fishing polyformaldehyde monofilament, graphene and thermoplastic polyurethane are blended, then polyformaldehyde is reinforced, toughened and modified, and the polyformaldehyde monofilament for fishing is preparedby melt spinning, three-stage thermal stretching and heat setting processes. A preparation method has the advantages of simple operation process and low production cost. The prepared reinforced and toughened polyformaldehyde monofilament for fishing can be used for polyformaldehyde rope nets, ocean trawls, breeding nets, polyformaldehyde ropes and the like.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

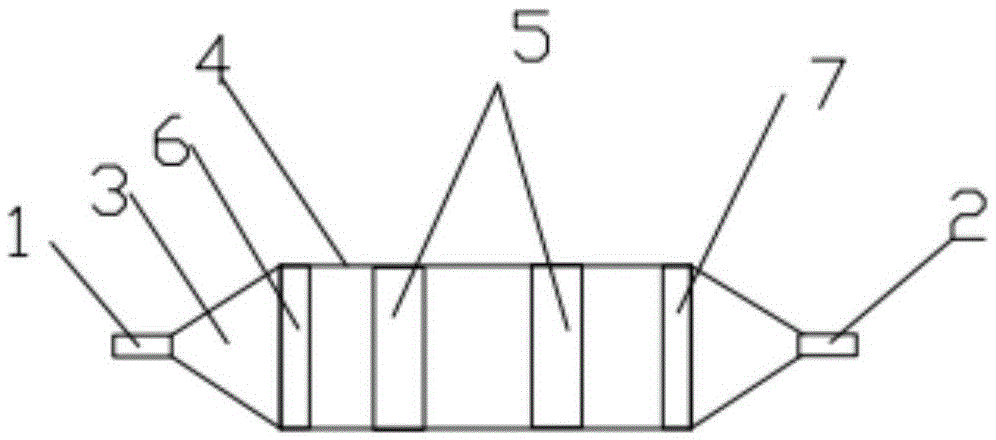

Filter screen electrolytic apparatus used for water treatment

InactiveCN105417796ALarger than surfaceWide variety of sourcesWater contaminantsTreatment involving filtrationWater flowOrganic matter

The invention relates to the technical field of water treatment and degradation, and more specifically relates to a filter screen electrolytic apparatus used for water treatment. The filter screen electrolytic apparatus comprises a liquid inlet and a liquid outlet, wherein cone-shaped tubes and an electrolytic bath welded with the cone-shaped tubes are arranged between the liquid inlet and the liquid outlet, the electrolytic bath is in a sealing state; the corresponding filter screen electrodes are arranged in the middle of the electrolytic bath, a filter block is arranged at front end of the filter screen electrode, and the filter block employs a ceramic micropore plate. According to the invention, the filter screen electrode is arranged in the electrolytic bath, degradation of an organic matter can be guaranteed, and at the same time, liquidity of water flow can be guaranteed, a structure space of the electrolytic bath is reduced, and the filter screen electrolytic apparatus has the characteristics of convenient usage, simple operation, good practicality and low cost.

Owner:TAICANG DONGNENG ENVIRONMENTAL PROTECTION EQUIP

Domestic sewage filter device

InactiveCN104163542BReduce impactLiquid flow is stableMultistage water/sewage treatmentEngineeringExhaust pipe

The invention discloses a filter material device for domestic sewage, which comprises two parts: a separating device and a filtering device; the separating device is a cylinder with a water inlet on the upper side of the cylinder and a support in the middle of the cylinder Column, on the supporting column, there is a movable separation pulverizer, and a water outlet is provided on the lower side of the cylinder; the filter device is a cylinder, and a water inlet is provided on the lower side of the cylinder, and the water inlet is connected with the separation device The water outlet on the upper cylinder is connected, and the water outlet is provided on the upper side of the cylinder, and there are multiple layers of filter material in the cylinder from bottom to top. Or other supports, and an exhaust pipe is arranged in the middle of the filter material. Because the present invention adopts the above-mentioned technical scheme, compared with the prior art, the present invention has the advantages of sufficient sewage degradation, fast purification, simple structure, and can meet the sewage discharge standard.

Owner:苗育卓 +1

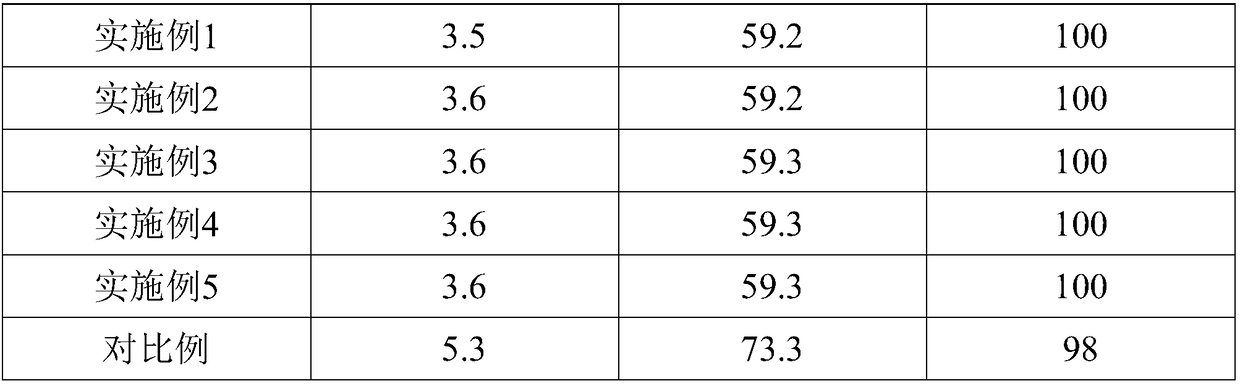

Crop slow-release fertilizer prepared by using edible fungus residue

InactiveCN108911849AReduced release rateControlled release rateMagnesium fertilisersAlkali orthophosphate fertiliserPhosphateMonopotassium phosphate

The invention discloses a crop slow-release fertilizer prepared by using edible fungus residue, and relates to the field of crop fertilizers. The crop slow-release fertilizer comprises a slow-releasefertilizer matrix, a slow-release fertilizer coating film and a binder, wherein the slow-release fertilizer matrix comprises the following raw materials in parts by weight: 200-300 parts of bauxite-modified edible fungus residue, 120-180 parts of urea, 70-100 parts of potassium dihydrogen phosphate, 35-55 parts of ammonium chloride, 15-35 parts of ammonium sulfate, 8-16 parts of magnesium aluminosilicate, 40-80 parts of an amino acid compounding agent, 20-45 parts of potassium sulfate, 5-9 parts of ferric chloride, 30-50 parts of soybean meal and 3-7 parts of fulvic acid; and the slow-releasefertilizer coating film comprises the following raw materials in parts by weight: 50-80 parts of polylactic acid, 30-40 parts of starch, 30-50 parts of bamboo fiber compounded polyhydroxybutyrate, 25-30 parts of polypropylene and 6-8 parts of propylene glycol monomethyl ether acetate. The prepared slow-release fertilizer has abundant nutrition and slow release rate, and the slow-release fertilizercoating film can be easily degraded and do not pollute the lands.

Owner:安徽省舒城久富田经济发展有限责任公司

A kind of recombinant spidroin protein and its use

ActiveCN110117328BWith controlled degradationWide range of usesMonocomponent protein artificial filamentOrganic non-cellulose fibresMicroorganismSpider Proteins

A recombinant spidroin protein provided by the present invention, the sequence structure includes: at least two spidroin protein domain monomers, and at least one protease cleavage site; the protease cleavage site is located in two adjacent Between spidroin domain monomers; by inserting a protease cleavage site between two adjacent spidroin domain monomers, when the recombinant spidroin protein is used in vitro, it can bind tool enzymes to control recombination Enzymatic hydrolysis of spidroin protein, compared with the existing spidroin protein that needs to be slowly degraded for a long time with the assistance of microorganisms, the recombinant spidroin protein of the present invention has the advantage of controllable degradation. When the recombinant spidroin protein is used in the human body, Since the protease cleavage site on the recombinant spidroin protein can be hydrolyzed by enzymes in the human body, the biological material made of the recombinant spidroin protein can be slowly degraded in the human body, improving the application value of the recombinant spidroin protein. more extensive.

Owner:SUZHOU BAIYUAN GENT CO LTD

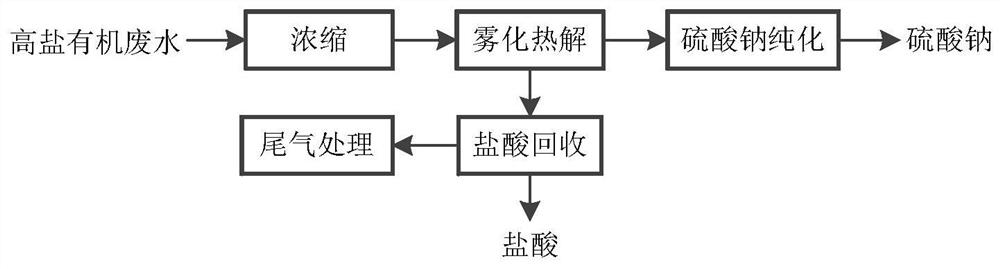

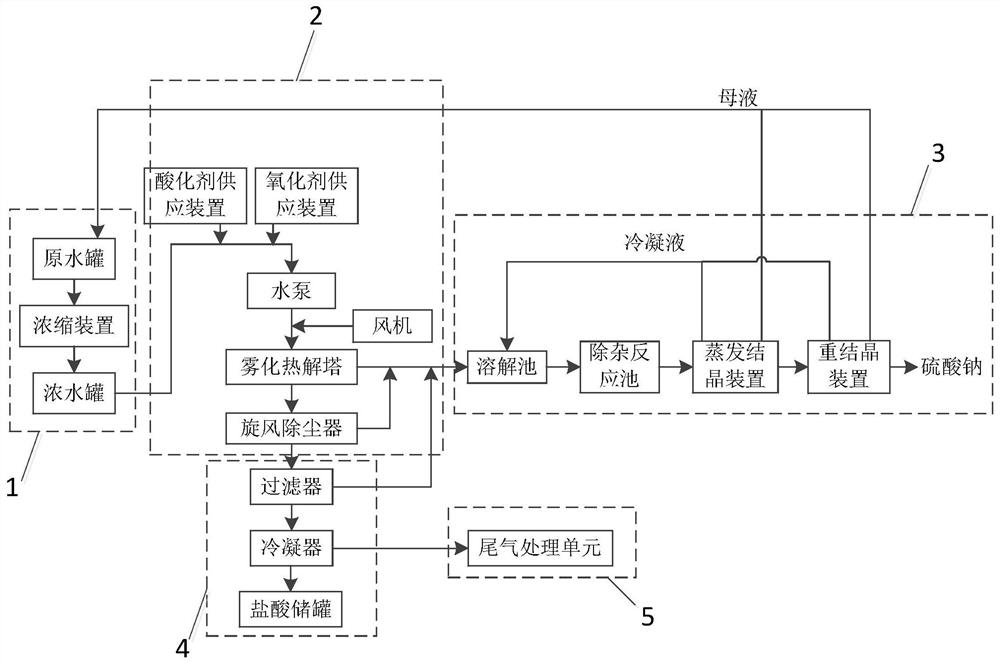

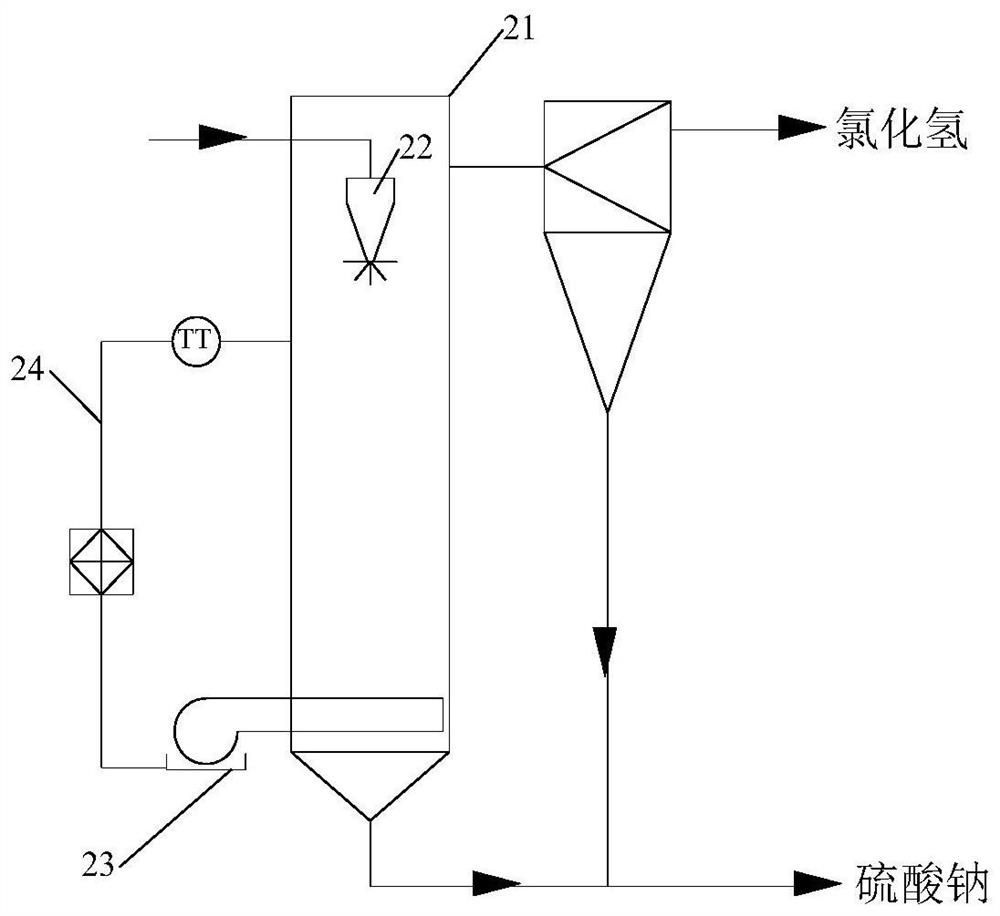

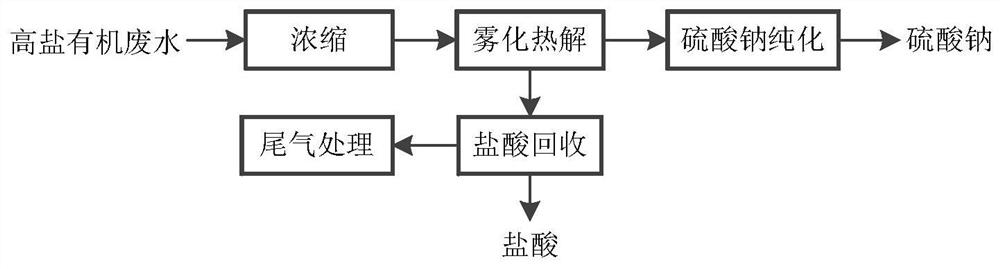

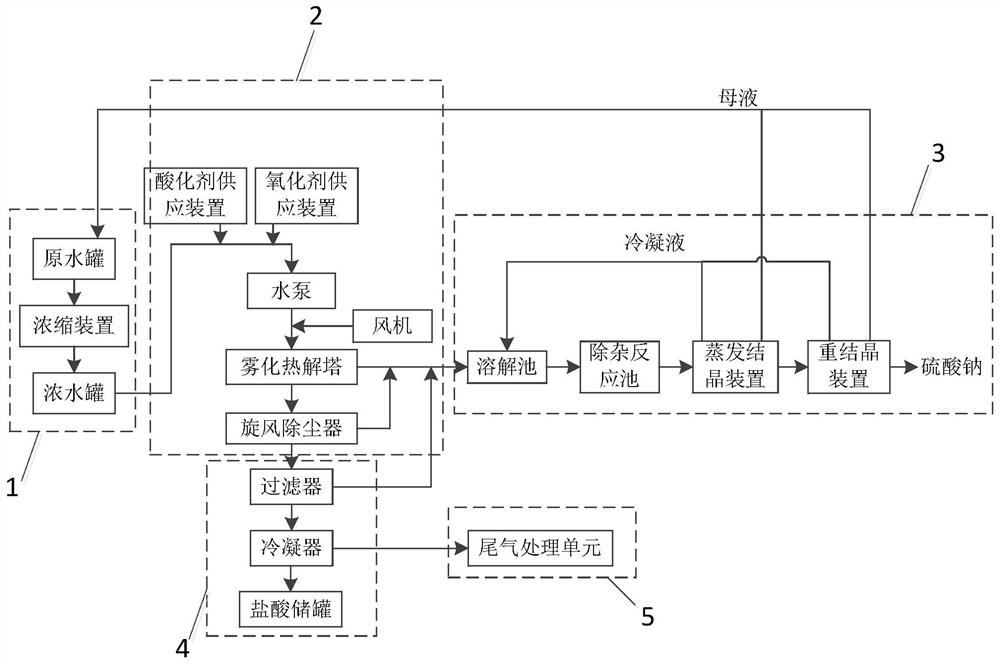

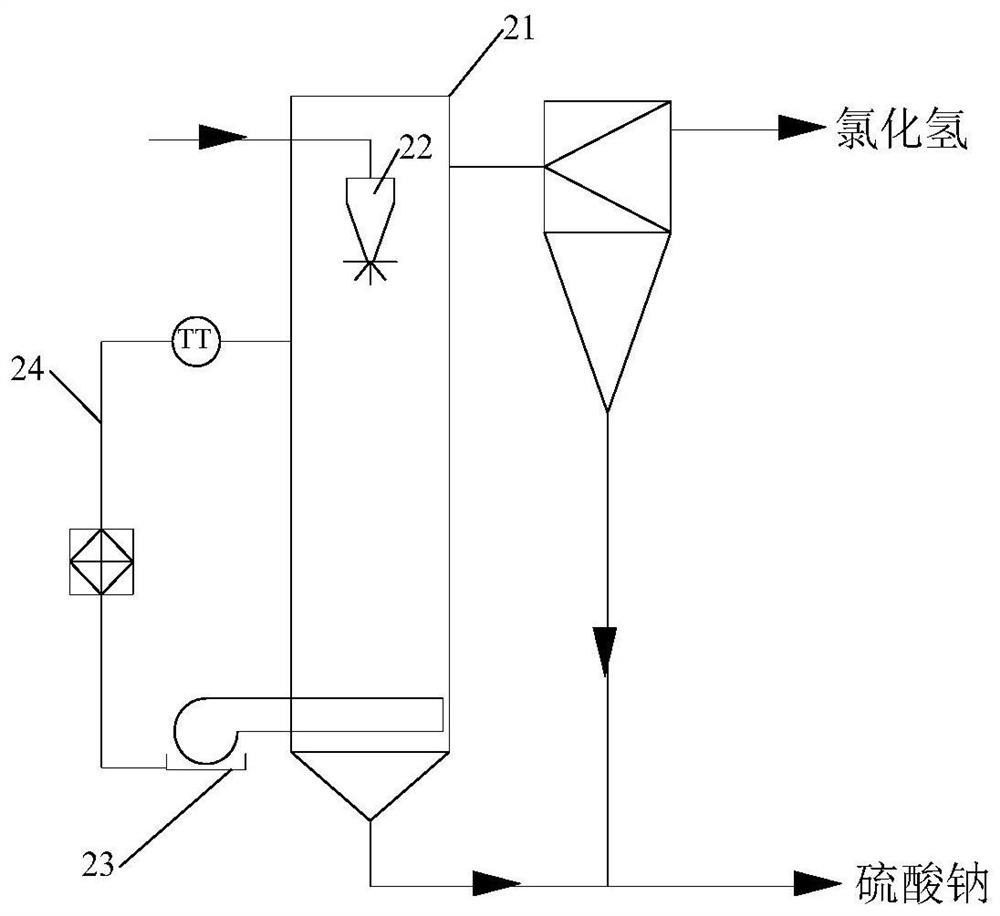

A system and method for resourceful treatment of high-salt organic wastewater

ActiveCN112225377BReduce consumptionIncrease concentrationChlorine/hydrogen-chloride purificationWater contaminantsOrganic matterHydrogen chloride

A system and method for resourceful treatment of high-salt organic wastewater, the system includes five units of raw water concentration, atomization pyrolysis, sodium sulfate purification, hydrochloric acid recovery and tail gas treatment. The raw water concentration unit concentrates the high-salt organic wastewater; the atomization pyrolysis unit adds an acidifying agent to the concentrated solution for acidification, and at the same time adds an oxidant, then atomizes and pyrolyzes the organic matter in the water to completely oxidize and remove, and separates to obtain hydrogen chloride gas and sodium sulfate. Mixed salt; the sodium sulfate purification unit dissolves, removes impurities, evaporates and crystallizes the separated sodium sulfate mixed salt, and the sodium sulfate is purified through recrystallization; the hydrochloric acid recovery unit filters and condenses the separated hydrogen chloride gas to recover hydrochloric acid; tail gas The processing unit deacidifies and purifies the remaining tail gas of the hydrochloric acid recovery unit. The system and method can realize high-efficiency removal of organic matter in high-salt wastewater, and recover hydrochloric acid and sodium sulfate crystalline salt at the same time; realize resourceful treatment of high-salt organic wastewater, and have good application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A kind of polyoxymethylene monofilament for fishing and its preparation method and application

ActiveCN110129921BImprove spinnabilityImprove performanceMonocomponent synthetic polymer artificial filamentConjugated synthetic polymer artificial filamentsPolyoxymethylenePolymer science

The invention discloses a polyoxymethylene monofilament for fishing, which is made of the following components in parts by weight: 75-90 parts of polyoxymethylene, 0.5-3 parts of graphene, 7.5-17 parts of thermoplastic polyurethane, and 0.5 parts of antioxidant 3 parts, 0.5-1 part of formaldehyde absorbent, 0.5-1 part of formic acid absorbent, 0.5-1 part of lubricant. The polyoxymethylene monofilament for fishery provided by the present invention uses graphene and thermoplastic polyurethane to blend and then strengthens and toughens the polyoxymethylene. Polyoxymethylene monofilament has the advantages of simple operation process and low production cost. The reinforced and toughened polyoxymethylene monofilament for fishery prepared by the invention can be used in polyoxymethylene rope nets, ocean-going trawls, breeding nets, polyoxymethylene ropes and the like.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

System and method for resourceful treatment of high-salt organic wastewater

ActiveCN112225377AAchieve removalEfficient removalChlorine/hydrogen-chloride purificationWater contaminantsRaw waterProcess engineering

The invention discloses a system and a method for resourceful treatment of high-salt organic wastewater. The system comprises five units, namely a raw water concentration unit, an atomization pyrolysis unit, a sodium sulfate purification unit, a hydrochloric acid recovery unit and a tail gas treatment unit. The raw water concentration unit is used for concentrating the high-salt organic wastewater; the atomization pyrolysis unit is used for adding an acidifying agent into the concentrated solution for acidifying, adding an oxidizing agent at the same time, thoroughly oxidizing and removing organic matters in water through atomization pyrolysis, and separating to obtain hydrogen chloride gas and sodium sulfate mixed salt; the sodium sulfate purification unit is used for dissolving the separated sodium sulfate mixed salt, removing impurities, evaporating and crystallizing, and purifying sodium sulfate through recrystallization; the hydrochloric acid recovery unit is used for filtering and condensing the separated hydrogen chloride gas and recovering hydrochloric acid; and the tail gas treatment unit is used for deacidifying and purifying residual tail gas of the hydrochloric acid recovery unit. According to the system and the method, organic matters in the high-salinity wastewater can be efficiently removed, and hydrochloric acid and sodium sulfate crystalline salt can be recycled; the resourceful treatment of the high-salt organic wastewater is realized, and the method has a relatively good application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

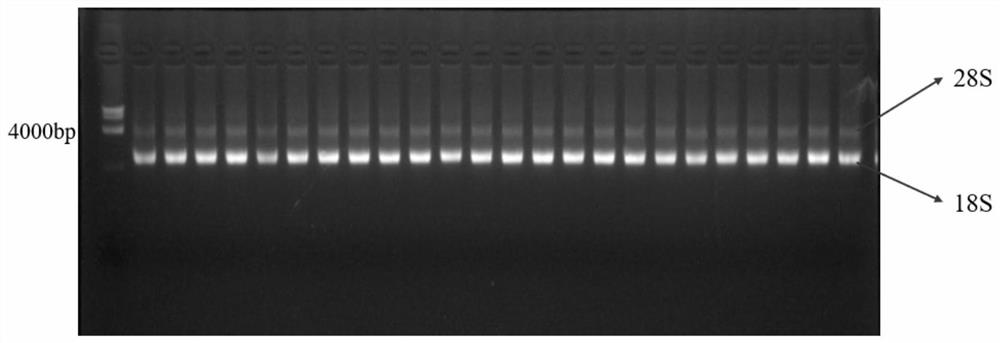

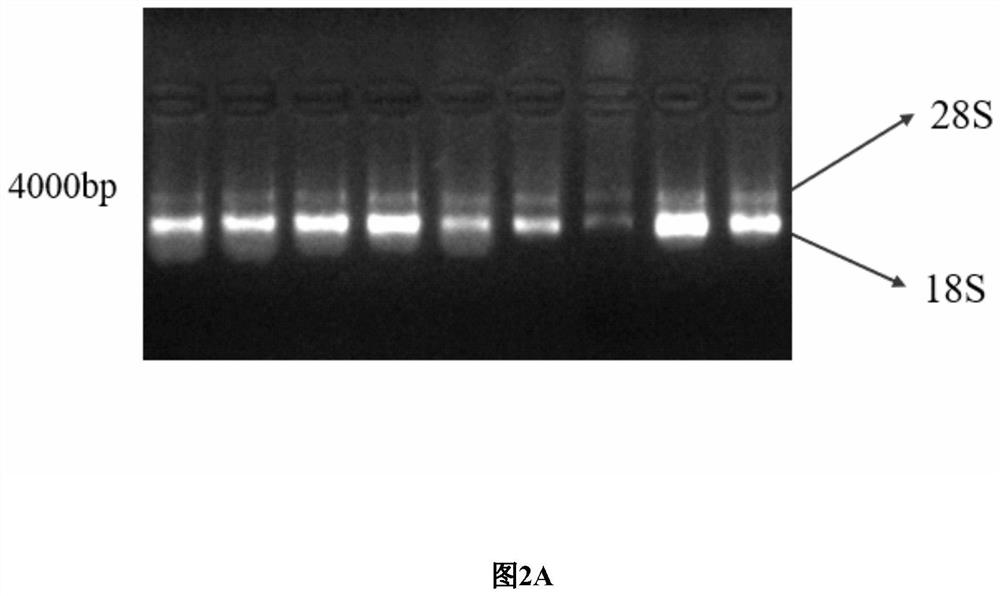

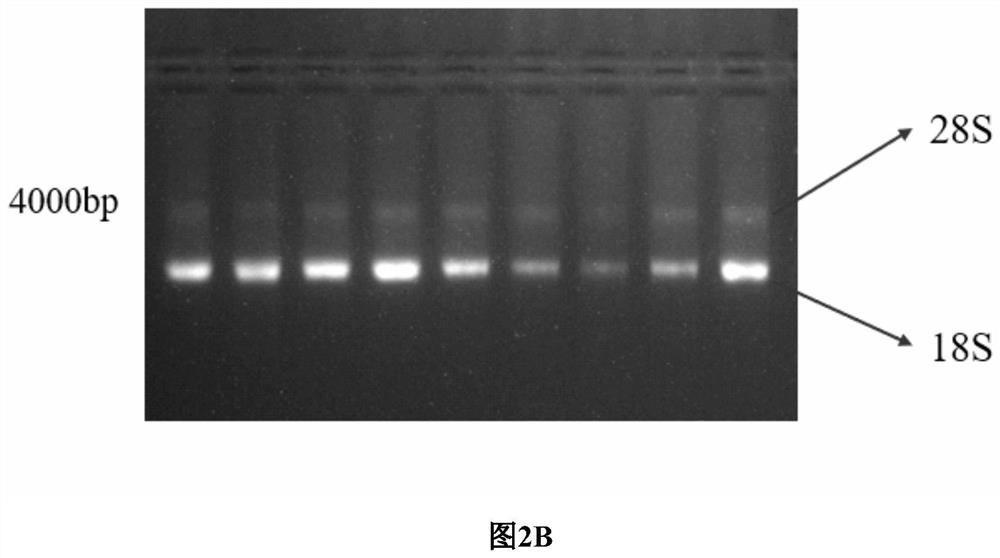

Method for extracting total RNA from hemolymph of procambarus clarkii

InactiveCN112458079AQuality improvementKeep aliveMicrobiological testing/measurementDNA preparationBiotechnologyTotal rna

The invention belongs to the technical field of preparation technology of RNA samples from aquatic animals, and specifically relates to a method for extracting total RNA from hemolymph of procambarusclarkii. The method includes two main steps of extracting the hemolymph of procambarus clarkii and separating blood cells and extracting the total RNA from the hemolymph samples. The extraction of thetotal RNA can be completed with only a small amount of hemolymph, so that the procambarus clarkii can be still alive after blood drawing, and the observation and study on the genetic changes in the bodies of the procambarus clarkii can be continuously carried out. The extracted total RNA is excellent in quality and little in degradation and can be used for high-throughput sequencing; and the method is low in cost, simple in operation and stable in extraction effect, and can guarantee the activity of the procambarus clarkii while extracting the total RNA from the hemolymph.

Owner:HUAZHONG AGRI UNIV

Environmentally-friendly degradation film

The invention relates to an environmentally-friendly degradation film, which comprises 50-80 wt% of film-grade polyethylene and 20-50 wt% of film-grade polylactic acid. According to the present invention, polylactic acid is an ideal fully-degradable plastic, such that the degradable plastic films with different degradation rates can be prepared by blending the film-grade polylactic acid and the film-grade polyethylene; the environmentally-friendly degradation film can be produced by using the common plastic film blowing machine, wherein the film-grade polylactic acid and the film-grade polyethylene are uniformly mixed during the production, and the degradable plastic film can be blown through the plastic film blowing machine; and the environmentally-friendly degradation film comprises thepolylactic acid and the film-grade polyethylene plastic, and the polylactic acid can be automatically decomposed at the ambient temperature of higher than 55 DEG C or under the action of rich oxygen and microorganisms, such that the waste polylactic acid film can be degraded in the waste environment.

Owner:TIANJIN KAIXUAN PLASTIC PROD

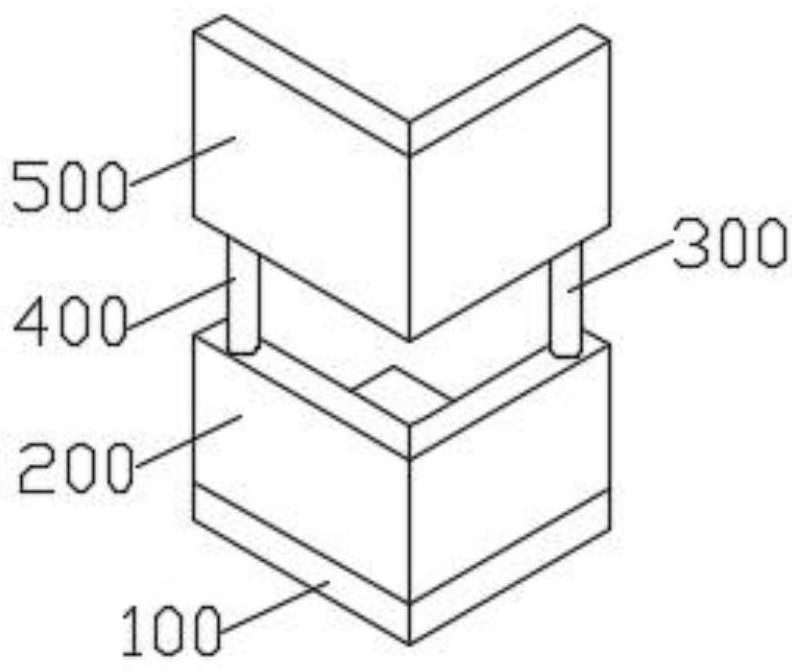

Fixing part for bottom of paper-plastic product and preparation method of fixing part

InactiveCN112238619AAvoid deformationGuaranteed degradationOther accessoriesMetal working apparatusStructural engineeringMechanical engineering

The invention discloses a fixing part for the bottom of a paper-plastic product and a preparation method of the fixing part. The fixing part comprises a fixing base, two lower side baffles are installed on the fixing base, a screw rod is installed on one lower side baffle, a guide rod is installed on the other lower side baffle, two upper side baffles are arranged above the two lower side baffles,the screw rod is in threaded connection with one upper side baffle, and the guide rod is in sliding connection with the other upper side baffle. According to the fixing part, through the arrangementof the screw rod and the guide rod, the distance between the upper side baffles and the lower side baffles can be adjusted, the fixing part can be installed at the corner position of the bottom of thepaper-plastic product, fixing of the corner positions of the paper-plastic product at different heights is achieved, and the paper-plastic product is effectively prevented from deforming in the usingprocess; and when the fixing part is degraded, no pollution component is generated, safety and environmental protection are achieved, meanwhile, the degradation rate is high, and the 25-day degradation rate of the fixing part for the bottom of the paper-plastic product is 99% to 99.5% through GB / T 20197-2006 measurement.

Owner:东莞市创新新材料开发有限公司

Special long-acting slow release composite fertilizer for cotton

InactiveCN108976005AReduced release rateNo wasteSuperphosphatesCalcareous fertilisersPolyvinyl alcoholMonocalcium phosphate

The invention discloses a special long-acting slow release composite fertilizer for cotton, and relates to the field of a composite fertilizer. The composite fertilizer is prepared from a composite fertilizer nutrient and a slow release coating film, wherein the composite fertilizer nutrient is prepared from the following raw materials in parts by weight: 100 to 160 parts of bauxite modified edible fungus dregs, 80 to 100 parts of manure organic fertilizers, 40 to 60 parts of urea, 35 to 55 parts of monocalcium phosphate, 20 to 35 parts of ammonium phosphate, 10 to 15 parts of molybdenum trisulfate, 16 to 22 parts of potassium chloride, 13 to 18 parts of copper sulfate, 22 to 28 parts of ammonium chloride, 6 to 10 parts of potassium sulphate, 16 to 20 parts of sodium nitrate and 28 to 36 parts of crop straws; the slow release coating film is prepared from the following raw materials in parts by weight: 60 to 80 parts of polylactic acid, 30 to 40 parts of starch, 25 to 45 parts of bamboo fiber composite polyhydroxybutyrate, 30 to 40 parts of polyvinyl alcohol, 10 to 15 parts of hydroxymethyl propyl cellulose and 5 to 6 parts of propylene glycol methyl ether acetate; the composite fertilizer contains organic fertilizers and inorganic fertilizers; meanwhile, the release speed of the composite fertilizer is low; the fertilizer waste and the excessive development of the cotton rootsystem cannot be caused; the slow release film has degradation performance; the pollution cannot be caused on the land.

Owner:安徽省舒城久富田经济发展有限责任公司

A method for extracting capsaicin and capsanthin from capsicum oleoresin

ActiveCN103910646BReduce consumptionImprove efficiencyCarboxylic acid amide separation/purificationNatural dyesChromatographic separationWater vapor

The invention relates to a method for extracting capsaicin and capsanthin from capsicum oleoresin. The method adopts a low temperature efficient dynamic reflux continuous forward single stage or forward and reverse multistage extraction manner, thus having good extraction effect and high efficiency; the method uses less solvent, thus saving labor cost, reducing energy consumption, and improving production efficiency. A negative pressure steam concentrator used in the method can reduce the temperature of steam to be less than 65DEG C, so that the capsanthin product is guaranteed not to be degraded due to overhigh temperature, and a large amount of heat resource is guaranteed to be used for heating so as to improve the efficiency and the use ratio of the heat resource. By adopting airtight continuous mechanical operation, liquid-liquid extraction and chromatographic separation, the method obtains over 98% of s high contentcolorless capsaicin and more than 480E of non-spicy capsanthin, and also improves labor efficiency, the use ratios of the capsaicin and capsanthin in the raw material are over 98%, and environmental pollution is also avoided.

Owner:蒋悦茜

Catalytic combustion treatment method for chlorine-containing organic waste gas

PendingCN114165797AHigh selectivityExtended service lifeHeterogenous catalyst chemical elementsIncinerator apparatusActivated carbonExhaust fumes

The invention discloses a catalytic combustion treatment method for chlorine-containing organic waste gas, and solves the problems of incomplete oxidation, catalyst poisoning, generation of high-toxicity byproducts, high cost and the like in the catalytic combustion treatment of the chlorine-containing organic waste gas. The chlorine-containing organic waste gas is treated and then introduced into an activated carbon adsorption bed for adsorption, and the activated carbon adsorption bed is switched after adsorption saturation; after being heated by a heater, air is fed into a saturated activated carbon adsorption bed to be subjected to desorption treatment, and gas led out after desorption treatment is heated and then is fed into a catalytic combustion reactor to be subjected to a catalytic combustion reaction; wherein the catalytic combustion reactor is filled with a catalyst A, a barrier medium and a catalyst B; the catalyst A is a catalyst for catalytic combustion of chlorine-containing VOCs; the catalyst B is an HCl oxidation catalyst. The method disclosed by the invention is simple, high in conversion rate and Cl2 selectivity, low in equipment investment and operation cost, long in service life of the catalyst and equipment and capable of recycling byproducts.

Owner:WUHUAN ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com